The weekend read: TOPCon boosts demand for EU equipment

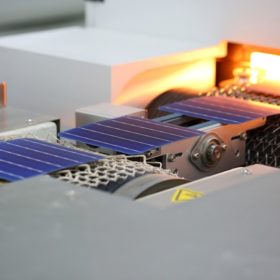

Photovoltaic manufacturers in Asia are importing deposition reactors from the EU to test the latest word in silicon solar cell passivation. Two thin buffer layers sandwiched between silicon wafers and metal contacts are increasing the efficiency of conventional solar cells and setting new records. Equipment suppliers expect the technology to spread through the industry and boost their bottom line.

UNSW, Leadmicro to partner on ALD for PERC production

UNSW Sydney has partnered with Leadmicro to develop the next generation of PERC solar cells and fast-track their time to market. The Chinese PV production machinery manufacturer is donating $1 million Atomic Layer Deposition (ALD) reactor to UNSW to test and adapt a new process for PERC cell solar cell production.

Hanwha supplying 100 MW mono PERC modules to China project

Hanwha Q Cells is continuing its collaboration with CGN Power Group. The manufacturer is delivering its Q.Peak-G5 mono-crystalline PERC solar modules to a 150 MW site in China’s Hubei province.

Longi sets new PERC module efficiency record

Chinese monocrystalline manufacturer Longi Solar Technology has broken its own record for PERC module efficiency, reaching 20.83% in independent testing conducted by TÜV Süd.

TOPCon: The next big thing after PERC

TOPCon technologies could further increase solar cell efficiencies, said Guangyao Jin, chief scientist, DuPont Photovoltaic Solutions, at this year’s Energy Taiwan, held in September. He added that metallization paste is crucial.

EU PVSEC: “Multicrystalline silicon will not die”

At first glance, the European PV conference this week has confirmed the widespread view that the upswing of monocrystalline technology will accelerate. But a closer look reveals that multicrystalline solar cells are still in the game.

Better bifacial adoption, catalyzing innovation focus of Future PV Roundtable at REI

pv magazine’s Future PV Roundtable, held at the 2018 Renewable Energy India (REI) Expo in Greater Noida, discussed how India can better adopt bifacial solar cell and module technology – the future of power generation. Prominent industry speakers also put forth their views on how standards can catalyze solar innovation for India-specific challenges, and on PV materials and components for enhanced module efficiency and recycling.

Challenges and solutions for anti-LID treatment

In PERC modules, both light and elevated temperature induced degradation (LeTID) and light induced degradation (LID) must be mitigated. What makes this tricky, however, is that the mitigation process of the first, counteracts that of the second, says Karin Krauß, R&D project manager, Rehm Thermal Systems. At the pv magazine Roundtable in Taipei next week, she will discuss possible solutions with cell and module manufacturers, and EPCs.

PERC market to reach 158 GW by 2022

Taiwan-based analyst firm, WisolPro says the global capacity for PERC cells is rapidly increasing, with the technology likely to replace polycrystalline cells. HJT, thin film, and n-type PERT technologies are also on the rise.

Goldbeck Solar plans 150 MW of solar in the Netherlands

The EPC has been operating in the Dutch market for a while. It expects to commission 150 MW of solar PV over the next two to three years. In related news, a total of 772 dairy farms are participating in the FrieslandCampina Solar program.