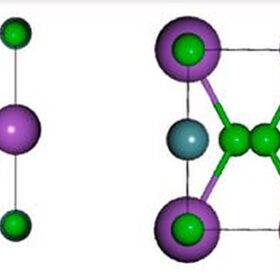

New perovskite material for lead-free solar cells

An Algerian research group has analyzed the electronic, elastic, optical, and thermoelectric characteristics of the KGeCl3 perovskite to verify if this lead-free material may be used for solar cells and other electronic devices. The scientists found that the novel material has a direct bandgap semiconductor with bandgap energies of 0.92 eV, 1.26 eV, and 1.88 eV for cubic, tetragonal, and orthorhombic phases, respectively.

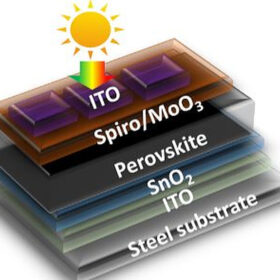

Perovskite solar cell built on steel substrate achieves record efficiency of 17.1%

Scientists in Australia claim to have achieved the highest efficiency ever reported to date for a perovskite solar cell built on a steel substrate. They utilized an indium tin oxide (ITO) interlayer between the steel substrate and the cell in order to avoid iron diffusion from the substrate into the PV device.

Sekisui Chemical unveils plan to produce solar thin films based on perovskite

A spokesperson from the Japanese plastics maker told pv magazine that production is currently being carried out at a small facility in the laboratory, and that the location of a full-scale production facility is currently under consideration.

Deployment trumps manufacturing in EU priorities

A lack of clear policy support, raw material dependency, and higher production costs are inhibiting the localization of European solar manufacturing, despite strong demand.

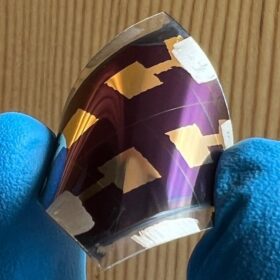

Flexible indoor perovskite solar cell achieves 32.5% efficiency

Italian scientists have developed a flexible indoor perovskite solar cell with 32.5% efficiency. Their design uses a PET substrate combined with a tetrabutylammonium bromide layer over the perovskite absorber. This additional layer effectively reduces defect density and enhances the stability of the underlying 3D perovskite structure.

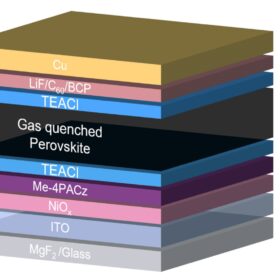

Imec presents inverted perovskite solar cell with 24.3% efficiency

The researchers of the Belgian research institute used a dual-layer treatment for the perovskite absorber, which they said improved the cell efficiency and stability. The device achieved an open-circuit voltage of 1.17 V, short-circuit density of 24.5 mA/cm2, and a fill factor of 84.6%.

NREL develops perovskite solar cells with 93% bifaciality

The National Renewable Energy Laboratory (NREL) has made highly bifacial perovskite cells with a front-side efficiency of 23%.

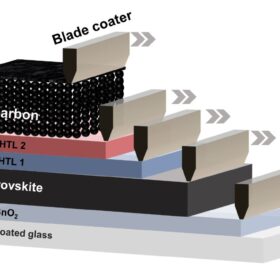

Fully printed carbon electrode perovskite solar cell achieves 19.2% efficiency

German scientists have fabricated a carbon electrode perovskite solar cell with a hole-transporting bilayer made of organic semiconductors instead of a conventional hole transport layer. They claim this approach improves the device’s fill factor and open-circuit voltage.

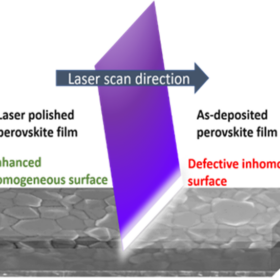

Commercial laser treatment to boost perovskite solar cell performance

European scientists used a nanosecond pulsed ultraviolet laser to reduce surface defects in perovskite films for solar cell applications. The result is a significant increase in cell efficiency and stability. The new technique may be particularly suitable for roll-to-roll (R2R) production lines.

GCL-SI unveils perovskite solar panel with 16.02% efficiency

GCL-SI has launched a new 320 W perovskite solar module. The company guarantees that the 10-year end power output will be at least 90% of the nominal output power, which decreases to 80% after 25 years.