Building the perfect perovskite, one layer at a time

A University of Cambridge-led team of researchers have demonstrated precisely controlled layer-by-layer epitaxial vapor growth of two-dimensional halide perovskite films in an industrially compatible process. Their findings could help develop more thermally stable perovskite solar cells.

Sharp offers space-qualified solar cells, plans perovskite-silicon tandem production

The Japanese technology company is offering three types of space-grade compound solar cell designs for satellites and spacecraft.

Inverted perovskite solar cell based on self-assembled monolayer achieves 26.92% efficiency

Researchers in China have developed an inverted perovskite solar cell approaching the 27% efficiency threshold. The device incorporates a specially designed self-assembled monolayer that passivates perovskite defects and enhances efficiency.

Key takeaways from Perovskite Connect 2025

Industry and researchers at the first global perovskite trade fair in Berlin discussed scalability, durability, and pathways to commercialization, with organizers already planning a second edition for October 2026.

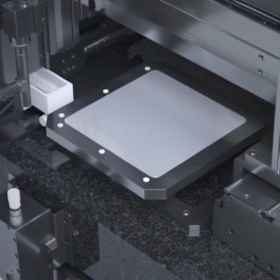

NPC Incorporated, Gosan Tech partner on perovskite solar module manufacturing

The alliance aims to utilize Gosan’s advanced inkjet printing technology in the manufacturing of perovskite modules, mainly for the Japanese and US markets.

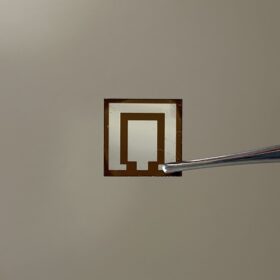

Tiny pinholes can lead to device failure in perovskite solar cells

Researchers in the United States have found microscopic pinholes in perovskites are responsible for the breakdown of such solar cells when under reverse bias conditions. They say the findings should push scientists and engineers to prioritize the production of pinhole-free films to make perovskites more robust and stable.

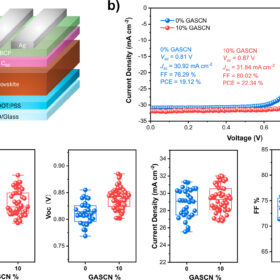

Researchers use guanidinium thiocyanate to raise perovskite cell efficiency

Researchers have used guanidinium thiocyanate as a chaotropic agent to modulate the crystal growth rate during perovskite crystallization. They compared different concentrations of the guanidinium thiocyanate. Champion device efficiency was 22.34%.

Perovskite rollout gathers pace

Perovskite’s growing visibility at industry events in 2025 is a sign that perovskites have progressed beyond the small lab-made devices seen earlier this decade. The focus is now on developing materials, processes, and a supply chain ready for large-scale manufacturing and deployment.

UK researchers developing new type of cadmium telluride PV panels for space applications

A team of UK researchers is working on lightweight cadmium telluride (CdTe) solar devices for space arrays. The aim is to develop 20%-efficient ultra-thin devices to provide lightweight, compact, lower cost solar power for satellites and space-based manufacturing applications.

Bottom-up cost model for perovskite solar module manufacturing

Scientists in Switzerland have conducted techno-economic analysis of perovskite solar module manufacturing costs in terms of levelized cost of energy and have found that these products could be competitive in the Alpine country provided that they achieve an efficiency of over 24% with a lifespan of 20 years and over 20% with a lifecycle of 30 years.