PV panel, battery production up to 45% more expensive in EU than in China, IEA finds

Despite the ongoing implementation of industrial strategies in other countries, the value of China’s exports will exceed $340 billion by 2035, according to the International Energy Agency.

A gulf between PV ambition and testing facilities

Though it already hosts several of the world’s largest PV installations, the Middle East and North Africa (MENA) region’s solar industry is still young, with limited local infrastructure and expertise. Project developers are learning quickly that building PV in harsh desert environments requires a careful eye on quality. New testing laboratories are looking to meet demand.

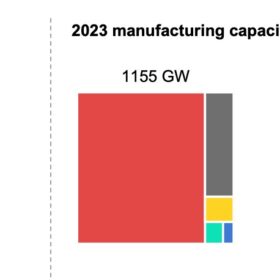

China’s solar dominance set to continue amid price slide

With solar module oversupply triggering a price freefall in 2023 and no recovery in sight, market consolidation, inventory pile-up, technology shifts, and challenges to reshoring PV manufacturing are set to affect all levels of the solar supply chain.

Turkey’s solar ambitions range beyond its borders

The number of module assembly businesses in Türkiye continues to rise but, despite protectionist moves to support domestic manufacturing, consolidation appears likely. Ambitions abroad, expansion at home, and interest from Chinese suppliers, were all on show at the recent SolarEX trade fair in Istanbul.

How drone EL mapping can help solar insurance claims

As the world becomes increasingly roiled by extreme weather, drone-based electroluminescence (EL) mapping can be a key weapon in the arsenal of solar investors.

EC announces European Solar Charter to support PV manufacturing

The European Commission (EC) has proposed the European Solar Charter (ESC) in response to the challenges facing the continent’s solar manufacturing industry. The document sets out a series of voluntary actions to be undertaken to support the EU photovoltaic sector and bears no mention of EU trade tariffs or restrictions on cheap solar panel imports.

ESIA releases action plan to support Europe’s PV manufacturing industry

The European Solar PV Industry Alliance (ESIA) has published a 10-point action plan geared toward delivering 30 GW of EU solar manufacturing capacity by 2030. It includes calls for targeted financial support, sustainability standards for PV units, and the development of a European Solar Academy and European PV Passport.

European coalition urges EU to support PV manufacturers

A position paper from Solar Industry Regions Europe (SIRE) says a balance must be struck between protecting the European solar market and reaching the market objectives of the energy transition.

Weekend Read: Thin prospects

The production of PV ingots and wafers remains the most highly concentrated of all the production stages in the silicon solar supply chain. Yet efforts to re-establish production in Europe and the United States are not for the faint-hearted.

Suniva buys production equipment to restart idled factory

Suniva has ordered equipment for thermal process steps annealing, diffusion and anti-reflective coating and passivation (PECVD) from Germany’s Centrotherm, as it proceeds with plans to expand high-efficiency monocrystalline silicon solar cell production in Norcross, Georgia.