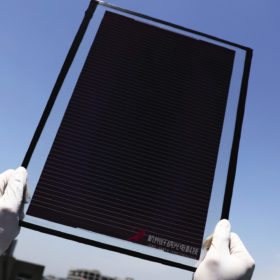

Chinese PV Industry Brief: Microquanta builds 12 MW ground-mounted project with perovskite solar modules

In other news, Haiyuan Material (HYM) said it will commission its 600 MW heterojunction cell factory in July and Polysilicon supplier Daqo announced it is seeking to raise RMB11 billion ($1.74 billion) through a share private placement.

Novel IBC solar cell architecture based on crystal photonics shows efficiency potential of 29.1%

Scientists in Germany designed a poly-Si on oxide (POLO) interdigitated back-contact (IBC) solar cell integrating photon crystals and found this architecture has the potential to reach a power conversion efficiency of over 28%, which would be 1% higher than the current practical limit set by the scientific community. They also found that by improving passivation, the efficiency may be raised up to 29.1%.

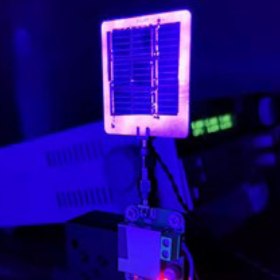

Photovoltaics for underwater wireless communication

Researchers in China used commercially available solar cells to create an underwater optimized lens-free system for high-speed optical detection and have found that the PV devices enable a much larger detection area than commonly used photodiodes.

All-polymer solar cell with 15.53% efficiency via meniscus-assisted coating

Scientists in China have developed an organic, all-polymer solar cell with a special meniscus-assisted coating technique. They claim that the power conversion efficiency of the cell is the highest among solution-printing-based, all-polymer solar cells.

Longi unveils 415W solar panel with 21.25% efficiency

The new product is mainly intended for use in commercial and industrial solar projects. It has a size of less than 2m² and features a short-circuit current below 15A.

Chinese PV Industry Brief: Hoshine plans 200,000 ton poly fab

Hoshine will invest $2.75 billion in the new polysilicon factory. Elsewhere, Irico New Energy today announced a strategic co-operation agreement with PV manufacturer Jinko Solar that will see it prioritize supply of solar panel glass.

TOPCon vs PERC – a battle between fast learning curves

TOPCon solar modules will gain more market share if their average efficiency, already higher than that of PERC panels, continues to improve, according to Stefan Glunz, PV research chief at Germany’s Fraunhofer Institute for Solar Energy Systems ISE. In an upcoming pv magazine webinar on the potential of TOPCon tech, Glunz will show how to reduce costs and increase efficiency.

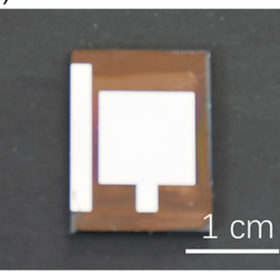

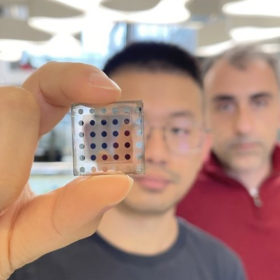

Solar cell based on silver bismuth sulfide nanocrystals achieves 9.17% efficiency

Scientists in Spain have fabricated a silver bismuth sulfide (AgBiS2) material with an absorption coefficient that is claimed to be 5-10 times greater than any other material currently used for PV technology. A cell built with these nanocrystals showed a power conversion efficiency of 9.17%, an open-circuit voltage of 0.495V, a short-circuit current of 26.75mA/cm2, and a fill factor of 63%.

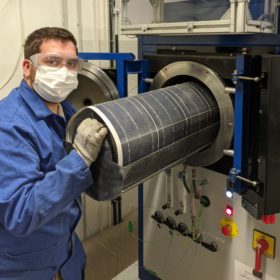

New PV module recycling tech from France

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.

India’s Borosil to expand solar glass production capacity to 2,000 tons per day

The solar panel glass manufacturer expects strong growth in demand for its products at home and abroad with a significant rise expected in the production of PV modules in the USA and Europe.