Best tech for intermediate-band solar cells

Researchers in Spain have analyzed the most important technologies for the development of intermediate-band solar cells (IBSC), a solar PV technology that was conceived to exceed the Shockley–Queisser limit. They identified four established technologies that are currently being adopted to manufacture IB materials and IBSC prototypes. Their future goal is to find the appropriate material to fabricate cheap and very efficient IBSCs.

NREL’s performance ratio method applied to thousands of PV systems

Researchers have analyzed the monthly performance ratio of 8000 PV installations distributed across the United Kingdom by using the calculation model of the U.S. National Renewable Energy Laboratory. They measured, in particular, thermal impact on the performance ratio (PR) and found that Spring and Summer seasons have higher monthly PR compared to Autumn and Winter.

Perovskite-based solar window tech from NREL

NREL’s new solar window darkens in the heat of the sun, producing electricity via embedded perovskite film. The tech is based on formamidinium-based metal halide perovskite, an inherently thermochromic material exhibiting significant optical changes.

Plasma passivation process to cut silicon cell costs

Scientists in Saudi Arabia have developed a new passivation process for n-type silicon solar cells, which they say could offer a simpler, lower-cost alternative to current processes used in manufacturing. The group fabricated wafers using this process with promising results, and now plans to integrate the process into a full silicon cell.

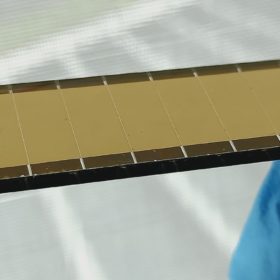

Mini perovskite solar panels with 18.4% efficiency

Researchers in Singapore have developed a 6.4 cm2 solar module based on co-evaporated methylammonium lead iodide (MAPbI3). They claim that the panel is a step forward in the industrialization of perovskite mini-modules.

US startup wins $7.6 million in funding for ribbon silicon furnaces

Leading Edge Equipment Technologies falls in the kerfless solar wafer or direct solar wafer category. Its “drop-in” manufacturing tech cuts wafer costs by 50%, drives up commercial PV power by 7%, and reduces manufacturing emissions by 50%. It’s the emissions piece that may be winning over investors.

Chinese PV Industry Brief: Stable wafer and cell prices and another 2.2 GW solar-plus-storage project

Solar manufacturers Longi and Tongwei have frozen next month’s prices.

Can CIGS thin-film PV manufacturing return in the US?

A scientist familiar with First Solar’s earlier efforts in CIGS makes the case for the CdTe pioneer to return to the technology.

The best PV module cooling technique

An international research team has analyzed all existing cooling technologies for PV panels and has indicated the current best options and future trends of research. According to its findings, active water cooling, although expensive and not particularly practical, is the most effective cooling technique while passive cooling systems, despite being easy to apply, have still limited possibilities.

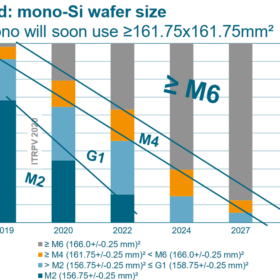

Update of the ITRPV roadmap shows three wafer formats will prevail

In an update to its International Technology Roadmap for Photovoltaics, the German engineering association the VDMA said that solar module sizes of up to 4.0m² may be brought to mass production in the future.