All-perovskite tandem solar cell with dipolar passivation achieves 30.1% efficiency

Researchers in China have developed a dipolar passivation method that reduces defects and improves charge transport in solar cells based on narrow-bandgap tin lead perovskite. The approach has enabled the fabrication of all-perovskite tandem solar cells with efficiencies of around 30% and enhanced stability,

Huasun unveils 770 W, 2,000 V heterojunction solar module

The Chinese manufacturer said the higher-voltage design of the new module reduces cable, combiner, pile-foundation, and land-use requirements, delivering balance-of-system savings of up to CNY 0.15 ($0.012)/W in western China. The module offers a power output of 730 W to 770 W and a conversion efficiency of up to 24.8%.

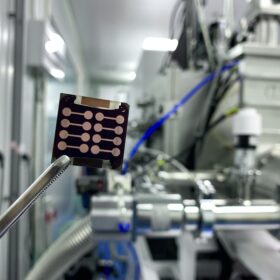

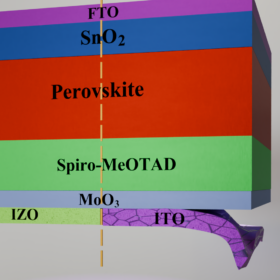

Highly transparent perovskite solar cell achieves 18.22% efficiency

A research team in India has investigated the use of highly conductive transparent electrodes based on amorphous indium zinc made with a room temperature process in perovskite solar cells. The devices could be used in tandem and building-integrated PV applications.

JinkoSolar achieves world record efficiency of 27.79% for TOPCon solar cell

The Chinese manufacturer says Germany’s Institute for Solar Energy Research Hamelin (ISFH) has independently verified the result.

New research sheds light on passivation-related defects in heterojunction solar cells

Korean researchers revealed that efficiency losses in heterojunction solar cells arise from two coexisting defect types – dangling bonds and weak silicon-silicon bonds. Their findings explain how hydrogenated amorphous silicon passivation help mitigate these defects and improve cell performance.

Spanish researchers developing rear-side concentrated PV modules for agrivoltaics

Researchers at University of Jaén in Spain have demonstrated a semi-transparent crystalline silicon solar photovoltaic module with rear-side optical concentrators for agrivoltaics applications.

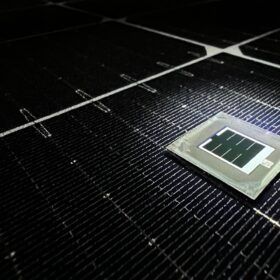

Plenitude tests perovskite-silicon tandem solar modules in utility-scale installation pilot

The Italian renewable energy company said it will validate Swift Solar’s 28% efficiency perovskite-silicon tandem technology in a utility-scale project.

Longi achieves 33.35% efficiency for flexible perovskite-silicon tandem solar cell

The Chinese manufacturer said the tandem device was developed through a dual-buffer layer strategy that improves interfacial adhesion while preserving efficient charge extraction. The efficiency result was certified by the US Department of Energy’s National Renewable Energy Laboratory (NREL)

South Korea sets 2030 goal for perovskite-silicon tandem solar panels

South Korea has allocated KRW 33.6 billion ($22.8 million) for R&D on perovskite-silicon tandem solar technology with a goal of commercializing 28%-efficient modules by 2030, according to the Ministry of Economy and Finance.

Photonic curing could accelerate transition to copper-metallized solar cells

Researchers in the United States have developed a photonic curing technique using laser sintering to rapidly heat and cure copper pastes on temperature-sensitive solar cell substrates without causing thermal stress. The process purportedly produces dense, low-porosity copper layers with strong adhesion to indium tin oxide, achieving low bulk and contact resistivity.