Improving solar panel recyclability with lasers

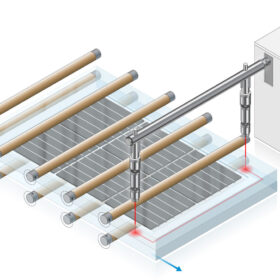

The National Renewable Energy Laboratory developed a proof of concept for a method to remove polymers from solar panel manufacturing to enable more efficient recycling.

New decapsulation tech for solar module recycling

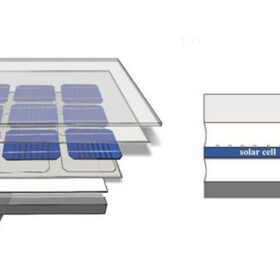

The Chinese Academy of Science has developed a new technique that uses non-toxic lemonene as a reagent to control the degree of EVA expansion during the decapsulation process of end-of-life photovoltaic modules. The proposed approach reportedly achieves the complete delamination of glass and backsheet without excessive damage to the solar cells

Solar waste may reach 1.2 GW annually in Australia

A new report has called for large PV waste and recycling facilities to be established in major Australian cities as a matter of priority with solar waste predicted to reach 100,000 tonnes annually, equivalent to 1.2 GW per year, by the end of the decade.

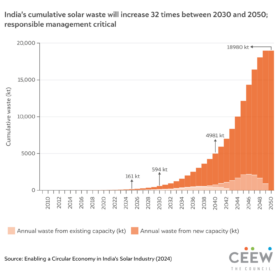

India’s cumulative PV waste to soar by 2050

India’s cumulative solar waste will increase to 600 kilotons (kt) by 2030 and 19,000 kt by 2050, according to a new report by the Council on Energy, Environment and Water (CEEW).

European consortium targets end-of-life PV panel silicon recycling

A European consortium of 11 commercial and non-profit organizations is developing several technologies to make use of end-of-life PV panels by either re-deploying them or by recovering and reprocessing the silicon.

Qcells, Solarcycle aim to jointly recover 95% of solar panel value

Qcells and Solarcycle have established the first US solar recycling alliance.

Hyundai acquires stake in German PV recyling specialist Flaxres

Flaxres says it will leverage Hyundai’s capabilities to expand its business outside of Germany. The company has developed a solar module recycling technology that is based on short-term high-temperature heating using flash lamps.

Solar panel waste is not a significant problem

Solar panel waste will not be a problem because there is so little of it. However, there is a short-term problem in some places because panel deployment is growing fast and recycling is playing catch up.

Netherlands raises solar panel recycling fee to ‘absorb shocks’ in market

PV module importers in the Netherlands saw the solar module recycling fee increase from €6.50 ($6.8) per ton to €40 per ton in July. In a chat with pv magazine, Jan-Willem Jehee, operations manager at Stichting Zonne-energie Recycling Nederland (ZRN), explains the money generated from the fee hike will be used to finance a guarantee fund that would ‘absorb shocks in the market should one occur.’

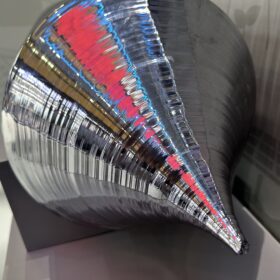

Indian scientists making high-purity polysilicon ingots from recyled PV cells

Indian scientists have produced high-purity polysilicon ingots from recycled solar cells using “spark plasma sintering” (SPS), and claim they may achieve a purity level comparable to commercially available products.