New PV module recycling tech from France

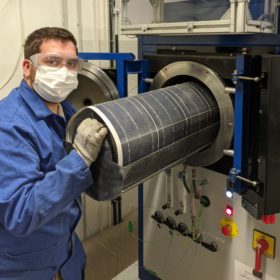

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.

Australia prepares for first solar ‘upcycling’ facility while recycling operations expand

As Australia stares down a deluge of worn out solar panels, recycling – and indeed upcycling – programs are grinding into gear. In Victoria, a site has been found for Australia’s first facility to recover and reuse solar module materials, while Reclaim PV has extended its manufacturer partner and pickup location lists.

Australian solar module manufacturer commits to recycling strategy

Reclaim PV has added another partner to its national solar panel recycling and recovery program with South Australian-based manufacturer Tindo Solar committing to a program that will see close to 100% of the solar PV panels that it handles recycled and re-used in the industry.

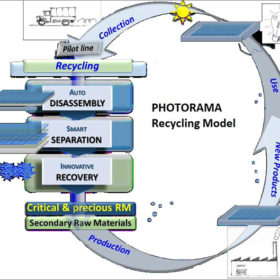

European consortium develops pilot line for complete PV module recycling

A European consortium consisting of Italian energy agency Enea and the French Alternative Energies and Atomic Energy Commission, among other entities, has developed a plan to build a low-emissions pilot line to recover critical and precious metals such as silicon, indium, gallium and silver. The line will be designed to reintroduce new materials and new products into the production cycle.

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

Circular economy could support India’s push for clean energy, self-reliance

The recovery of valuable raw materials from end-of-life solar panels and batteries presents a great opportunity for India to secure future supplies as the nation chases its ambitious renewable energy targets.

Recycling solar panels: Making the numbers work

NREL researchers said a profitable and sustainable solar panel recycling industry could establish itself by 2032. Here’s how the numbers work.

India may host massive amounts of PV module waste by 2030

India’s solar capacity growth up to 2030 also means the accumulation of a significant amount of PV module waste due to early failures or damage during transportation, installation, and operation. The waste generation could be 21 kilotons, assuming India’s cumulative installed PV capacity grows to 287.4 GW by 2030, from 40 GW in 2020. This doesn’t include end-of-life panel waste, as PV systems installed in the 2020-30 period are assumed to have at least 30 years of lifetime.

New process to recycle silicon, silver and glass from end-of-life PV panels

A €4.8 million EU-funded research project is aiming to develop a process that allows recovering all components of a photovoltaic module.

Managing solar PV waste in India

A new report compares the regulatory frameworks of the European Union and India to manage end-of-life solar panels. It also assesses and analyzes the PV waste market and processing capacities in India, while sharing recommendations for Indian stakeholders.