Spread over two editions of pv magazine this summer, Array Changing Technologies showcases more than 40 of the year’s top solar innovations, from new modules and inverters to the latest innovations in monitoring software and mounting systems.

Once again, pv magazine put together a jury of independent experts from across the global PV industry, who picked through this year’s bumper crop of entries to select a few choice products as particularly worthy of recognition, thanks to their potential to solve problems for industry players, push more watts out of solar installations or bring down the overall cost of deploying more solar.

After bringing the four jurors together for a lively debate, the following have been selected as 2018’s Array Changing Technologies:

Joint winner: NEXTracker: TrueCapture

![]() NEXTracker states that its TrueCapture system can increase plant yield by up to 6%. It does this by drawing from the latest meteorological forecasts on diffuse light conditions such as clouds, fog, or pollution particulates. Then its self-learning algorithm corrects panel direction to minimize production loss due to inter-row shading and clouds. Further, the system has smart panel sensors that provide real-time sensing information on each tracker row’s shading and light conditions. This approach is unique due to the incorporation of machine learning algorithms. These improve system behavior over time and let it adapt to local conditions.

NEXTracker states that its TrueCapture system can increase plant yield by up to 6%. It does this by drawing from the latest meteorological forecasts on diffuse light conditions such as clouds, fog, or pollution particulates. Then its self-learning algorithm corrects panel direction to minimize production loss due to inter-row shading and clouds. Further, the system has smart panel sensors that provide real-time sensing information on each tracker row’s shading and light conditions. This approach is unique due to the incorporation of machine learning algorithms. These improve system behavior over time and let it adapt to local conditions.

Jurors were impressed by this innovation’s ability to provide a verified gain in energy production from an installation, and to maximize ground coverage, whilst compensating for terrain and other factors.

“We are delighted to be selected by pv magazine for this year’s Array Changing Technologies 2018 award,” states Dan Shugar, NEXTracker CEO and founder. “With successful field deployments running in several countries totaling hundreds of megawatts, we’d like to thank our customers for collaborating with us, and proving that our TrueCapture smart control system can produce up to 6% more energy.”

Joint winner: Ferroamp Powershare

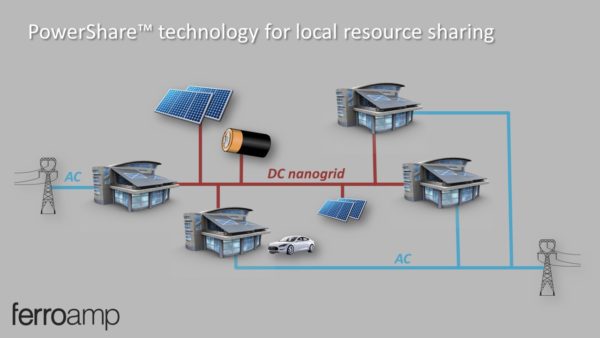

Current electricity grids are centralized, top-down systems. But what would a bottom-up system look like? Ferroamp’s Powershare is a good example of such an approach. It is a small-scale DC nano-grid shared by a small group of consumers as a backup to the main AC grid. The Powershare nano-grid consists of small-scale generation – usually PV and/or wind – and often also batteries and electric vehicle charging stations. A number of successful projects in Sweden have shown the feasibility of the solution by connecting local office buildings in a small grid. This provides them with backup electricity in the case of a power outage, but also creates a local microeconomy and reduces their electricity tariffs. The company acknowledges that regulatory hurdles exist in many countries in which there are few distribution companies with a natural monopoly. However, the European Union’s ‘Winter Package’ has taken steps toward opening up markets for micro-grids operated alongside traditional monopolies.

Current electricity grids are centralized, top-down systems. But what would a bottom-up system look like? Ferroamp’s Powershare is a good example of such an approach. It is a small-scale DC nano-grid shared by a small group of consumers as a backup to the main AC grid. The Powershare nano-grid consists of small-scale generation – usually PV and/or wind – and often also batteries and electric vehicle charging stations. A number of successful projects in Sweden have shown the feasibility of the solution by connecting local office buildings in a small grid. This provides them with backup electricity in the case of a power outage, but also creates a local microeconomy and reduces their electricity tariffs. The company acknowledges that regulatory hurdles exist in many countries in which there are few distribution companies with a natural monopoly. However, the European Union’s ‘Winter Package’ has taken steps toward opening up markets for micro-grids operated alongside traditional monopolies.

Ferroamp impressed the experts with it’s solution’s ability to prepare for a future of freedom from utilities and a grid based on multiple, distributed energy sources.

“We are really excited being recognized as winner in the PV Magazine Array Changing Technologies. This will help us spread the word about our novel PowerShare technology and its' possibilities to increase the profitability and versatility of PV installations on global markets,” says Björn Jernström, CTO, Ferroamp.

Highly commended: Cobalt Energy PV-Serve/PV-Vision

Inspection services are not as sensational and headline-grabbing as some parts of the PV value chain, but are a quiet achiever in the plant manager’s arsenal. U.K.-based Cobalt Energy offers the PV-Serve and PV-Vision solutions that work together to enable night-time electroluminescence inspections, dark I-V curve tracing, and bypass diode function checks. First, PV-Serve injects a reverse current flow into a given string or module. Then PV-Vision can capture high definition video and photographs of electroluminescence. Active cells emit a bright grey or white light, while damaged or inactive cells appear darker or even jet black. Detectable defects include: mechanical stresses, manufacturing defects, potential induced degradation (PID), and bypass diode failures.

Cobalt Energy’s solution was singled out by jurors for its portability, and potential to allow plant operators to hold manufacturers and EPC providers responsible for the equipment they install.

Both parts of the Array Changing Technologies 2018 feature are available in full from the feature page on pv-magazine.com. pv magazine would like to thank our expert jurors for their time, and all the companies who submitted products for sharing their latest innovations with us. Until next year!

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.