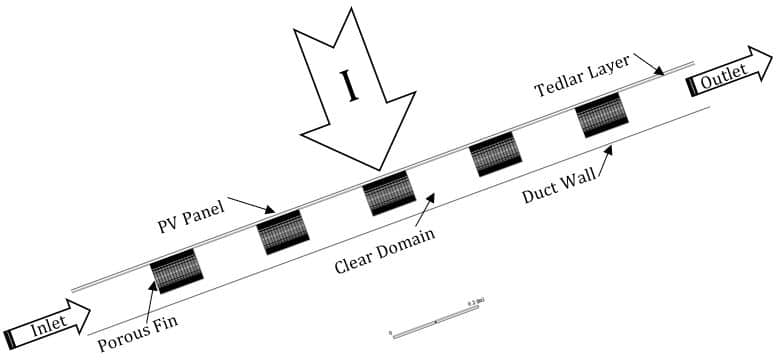

A research group from the Jordan University of Science and Technology and the Australian College of Kuwait have developed a new passive cooling technique for solar modules. The method is based on the use of an open-ended channel, partly filled with an isotropic porous material, with constant thermo-physical properties attached to the backside of the panels.

“The main purpose of using porous material is to extend the heat transfer area by increasing the solid-fluid interaction,” researcher Ali Mahmoud Khlefat told pv magazine. “Any highly conductive material such as copper and aluminum or alloy can be utilized in this regard keeping in mind that the efficiency enhancement would justify the added cost.”

The scientists used a discrete ordinates (DO) model, which facilitates the modeling of a solid zone with adjacent fluid or solid zones on either side as a semi-transparent medium. They chose this method to simulate the radiative heat transfer from the solar radiation, the heat transfer within the PV panel layers, and inside the channel.

With this model, the radiative transfer equation (RTE) – a five-dimensional integro-differential equation with three spatial and two-directional coordinates – was transformed into a transport equation for radiation intensity in the spatial coordinates.

“Air was a nonparticipating media in the radiation process and all other materials used in this study were gray-diffusive,” the researchers explained. “Gray materials are materials that have constant optical properties, i.e. the emissivity and absorptivity are independent of the wavelength of the incident solar irradiance.”

The validation of the simulation was based on a 2007 study and assumed that the panel was tilted at 45 degrees. It was performed with the date, time, longitudes, and latitudes of Bangkok, on a PV panel consisting of a glass cover, a PV layer, a Tedlar layer, and a flow porous layer. The module was exposed to constant heat fluctuations and its temperature and that of the Tedlar layer were assumed to be uniform.

“The PV panel type assumed in the study was the monocrystalline module JKM360M-72 from Chinese manufacturer Jinko with a maximum conversion efficiency of 18.55% and a temperature correction coefficient f 0.0045 K-1, under standard test conditions,” Khlefat said.

The analysis considered a range of different factors, including the convective coefficient, which is defined as the ratio of natural to forced convection. The scientists also looked at the Darcy number, which represents the relative effect of the permeability of a medium versus its cross-sectional area, and the inclination angle of the PV module. In addition, they considered the thickness ratios of the porous material, the conversion efficiency of the solar module, and the internal emissivity of the duct base material on the average Nusselt number. The Nusselt number is the ratio of convective heat transfer to conductive heat transfer at a boundary in a fluid.

Popular content

“It has been proven that the heat transfer from the backside of the PV panel was significantly increased by the proposed system,” the academics said. “The considerable enhancement in heat transfer from the PV panel was achieved because of the high kinetic energy that concurred with high values of the convective coefficient.”

The scientists found that increases in efficiency were proportional to the thickness ratios.

“A porous thickness ratio (SP/S = 0.7) was considered in the following analysis, to compromise between material cost and performance enhancement,” they said. “Moreover, several cases were studied to achieve the optimum configuration to dissipate the heat from the PV panel to the environment.”

The scientists were able to increase the panel efficiency by 6.73% with a three-fin porous layer, by 9.19% with a five-fin porous layer, and by 8.34% with a whole porous layer.

The cost of the proposed technology would depend on the amount of aluminum foam.

“Its cost is around $1 per kg for a minimum amount of 10 kg,” Khlefat stated. “For instance, the amount of aluminum foam needed for a 10-panel system will be around 14 kg, so the cost will be around $14 to install five porous blocks per panel, the percent increase in the output electrical power will be around 21.75%.”

The group presented the cooling technique, which has yet to be applied commercially, in “Thermal cooling of Photovoltaic panels using Porous Material,” which was recently published in Case Studies in Thermal Engineering.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I would like to know if radiative cooling with nano structure is in large scale possible. In theory PV modules can reflect the heat-part of the radiation spectrum, directly through the atmospheric window into space. So PV can be used, like white roofs or bright water for radiative solar management to mitigate the earth heat imbalance, caused by GHG.

This is a very interesting technique and a very efficient system to enhance the electrical output of PV systems, which will save a lot of cost if applied commercially.

hello,

can you suggest me some topics for PhD thesis, where i can work related research area

related to enhance the PV solar by using porous materials.

Thank You