The use of noise-based techniques for the testing of electronic components and solar cells is not new at the research level, although it has so far been applied to a very limited extent in PV research.

A group of Chinese scientists has recently utilized three types of noise to characterize different parts and types of defects in solar cells through a technique which they described as non-destructive and able to connect directly to the microscopic and medium scale defects in the solar cell materials.

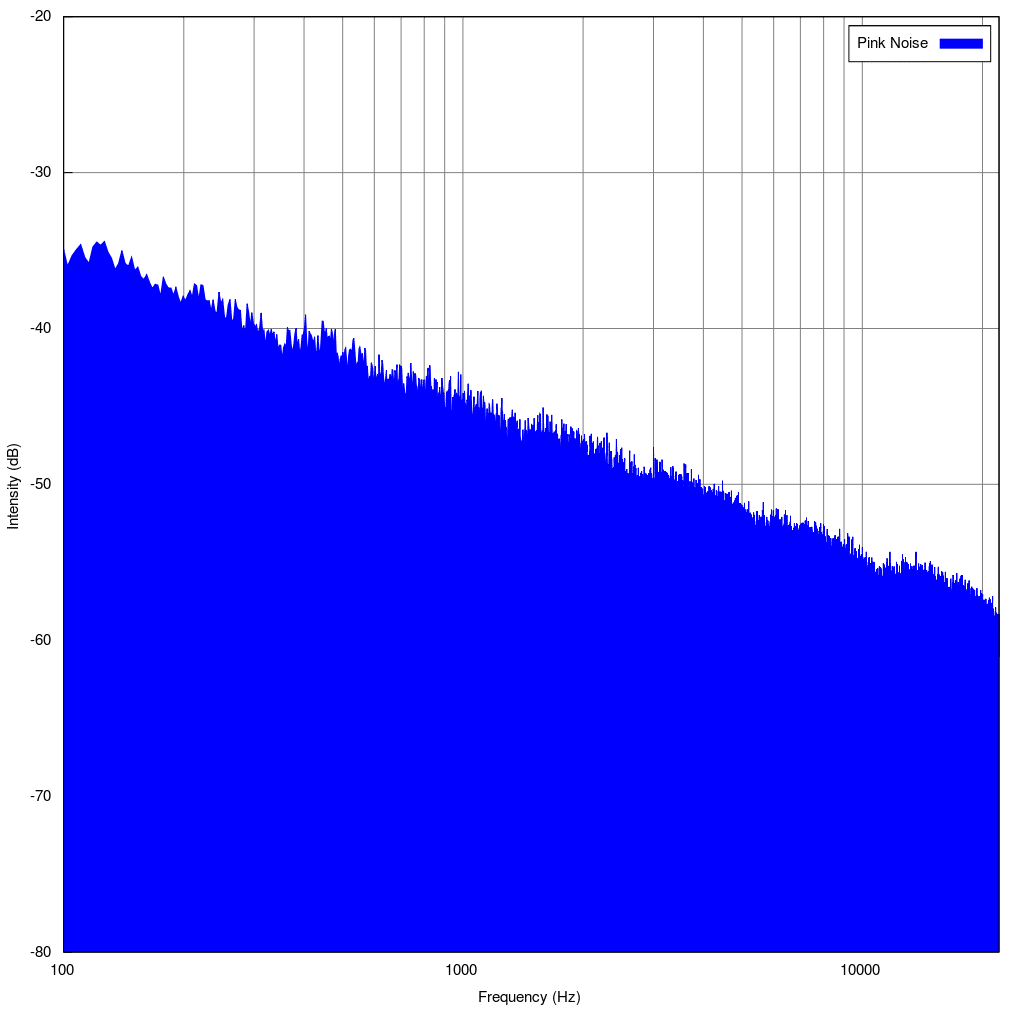

The researchers said that three types of noise were thus far identified in solar cells by previous research: the 1/f noise, which is also known as pink noise and is frequent in electronic devices as a low-frequency phenomenon and in PV devices originates from the diffusion mechanism and recombination mechanism of minority carriers; the so-called microplasma noise in p-n junctions; and the g-r noise caused by the fluctuation of the generation and recombination of electrons in semiconductor-based photon detectors.

“In solar cells, 1/f noise stems mainly from defects on the surface or interface, such as incomplete lattices, unsaturated dangling bonds, or transmission center capture,” the Chinese group explained. “Microplasma noise reflects from the metal impurities and micro-defect clusters in the area of electric charges in the p-n junction space. G-r noise arises mainly from the scattering effect of impurities at deep energy levels inside semiconducting materials on carriers, reflecting defects such as heavy metal contamination precipitation, dislocations, or split levels in the base region or emission-region materials.”

Popular content

The academics conducted high-temperature stress and radiation stress tests at room temperature on a monocrystalline cell. The tests led them to the conclusion the proposed technique is “superior” to others due to its high sensitivity and non-destructiveness. “In addition, noise can distinguish defects of different types at different parts of the cell, which is conducive to improving the production process and guiding the type selection of products,” they concluded. “Finally, noise can also function as a monitor of the reliability of some components and the encapsulation in a cell panel.”

Their experiment is presented in the paper Noise-based analysis of the reliability of silicon solar cells, published in AIP Advances.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.