The weekend read: What’s next for polysilicon?

The past 12 months have proved profitable for polysilicon manufacturers, as selling prices have soared to levels not seen since 2011. However, with major new capacity expansions on the horizon from most of the leading manufacturers, and new players planning to enter the scene, the market balance looks set to shift. Exawatt’s Alex Barrows rounds up where the industry stands and what might happen next.

The Hydrogen Stream: Hydrogen-powered heavy-lift unmanned aerial vehicle from Korea

UK research firm Wood Mackenzie reports that Northeast Asia and Europe are expected to become the main hydrogen importers, accounting for 55% of seaborne hydrogen trade, whereas Australia, the Middle East and, possibly, Russia and the U.S. have the greatest export potential. Plug Power and Lhyfe closed a deal to build green hydrogen generation plants throughout Europe.

Focus COP26: How can Africa attract more solar investments?

Africa has 40 % of the world’s solar potential but only 1 % of the world’s solar panels.

Solar Power Mexico ready to take off

Mexico’s largest solar event will take place from 9 to 11 November in Mexico City. The organizers presented the conference program in an online press conference.

Tesla orders 45 GWh of EV batteries from CATL

Reports calculated that the single order would be enough to support production of 800,000 vehicles.

Chinese PV Industry: Government announces deployment of 30 GW of renewables in northwestern China

Furthermore, TBEA has announced a plan to invest in four solar power plants and Flat Glass has agreed to acquire two quartz mines.

High module prices make Italy an early victim of supply chain disruption

Sergio Matalucci reports for pv magazine from the Key Energy event in Rimini on how the Italian solar market is currently dealing with the module price hike and the supply change disruption. According to the president of Italian association Italia Solare, difficulties to source modules in the market have intensified over the last four months.

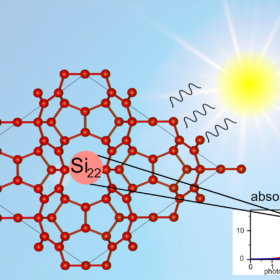

A whole new structure for silicon

Scientists in the United States theorized that a new allotrope of silicon – the same element arranged into a different atomic structure – could show greatly improved photovoltaic performance compared to that used in today’s solar cells. The allotrope, Si22, could also have important properties for use in quantum computing, carbon sequestration and other applications – though fabrication and actual physical testing of the material will be needed to back up the theoretical findings presented so far.

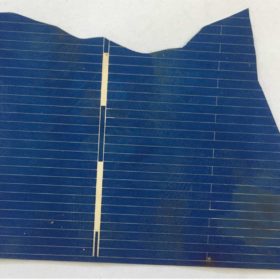

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

India launches tender for 50 GWh of battery cell output with subsidy support

The Indian authorities have opened global bids to set up advanced-chemistry battery cell manufacturing units in India under the production-linked incentive scheme. Applications are open until Dec. 31, but bidders must commit to setting up a minimum of 5 GWh of capacity to qualify for the government subsidy.