Currently accounting for around 5% of the market for solar modules, cadmium telluride is well established as a thin-film PV material, thanks largely to U.S. manufacturer First Solar. Though lower efficiency than today’s silicon modules, the material is able to compete on manufacturing cost, and there is plenty of room to push for higher efficiencies.

Much of the recent research into CdTe has focused on improving performance through the interface between layers at the front of the cell. And improvements here have now begun to shine a light on the limitations caused at the rear surface. This was the focus for scientists at the University of Toledo in the United States, who trialed a new material as a passivation layer on the rear side of a CdTe cell.

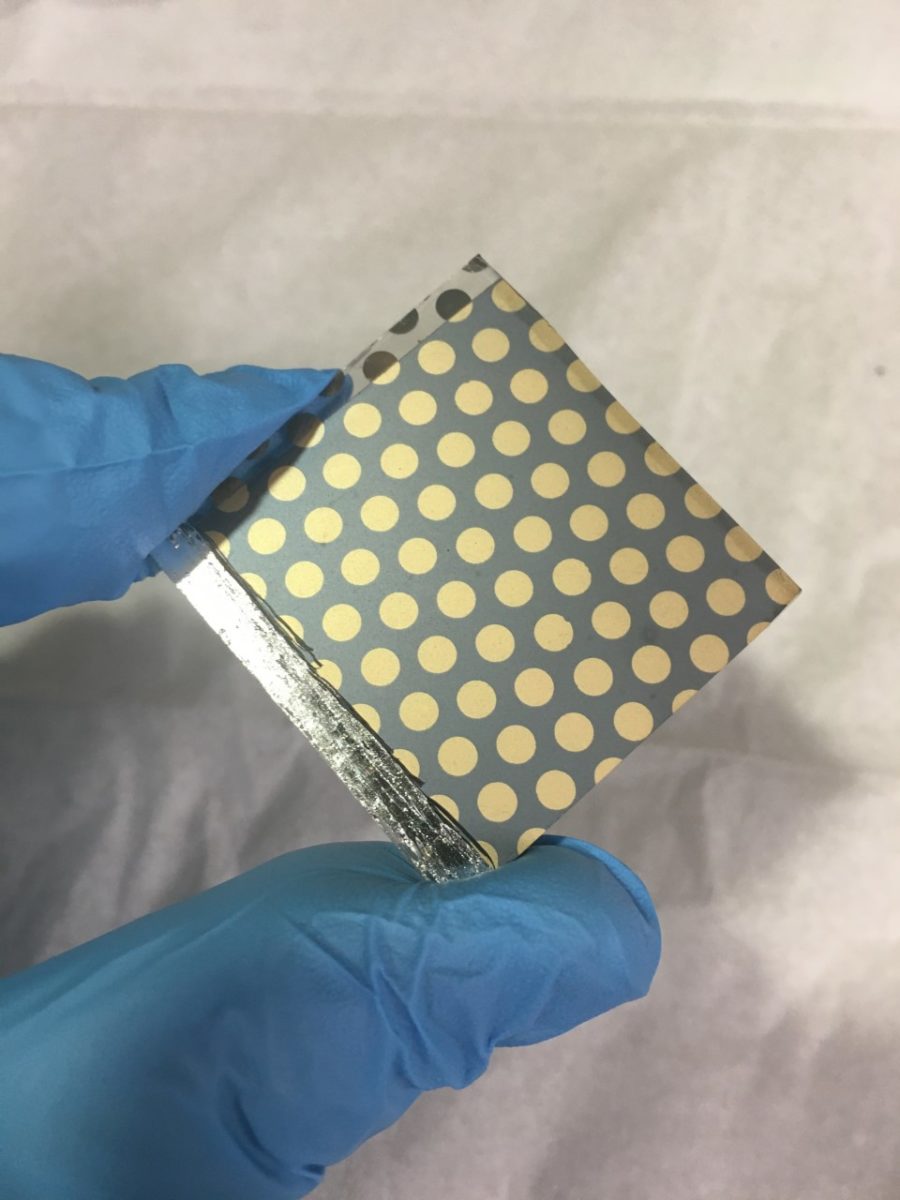

The group worked with solution-processed copper-aluminum oxide (CuxAlOy), and demonstrated that incorporating this material into the back surface of the cell led to improvements in performance. The work is described in full in the paper Improving CdSeTe Devices With a Back Buffer Layer of CuxAlOy, soon to be published in the IEEE Journal of Photovoltaics.

“We do not evaluate production cost,” University of Toledo researcher Manoj K Jamarkattel told pv magazine. “However, the outcomes of this research mainly focused to increase carrier lifetime and improve overall device efficiency which will obviously reduce dollars/watts for other production companies.”

Cells fabricated with the CuxAlOy layer reached efficiencies up to 17.4%, compared to 16.5% for control devices that the group fabricated without the additional back buffer layer.

Minority carrier lifetime

Contributing to the efficiency, the group notes that the back buffer layer allowed for rapid improvement to the cell’s minority carrier lifetime, and that furthering their understanding of the mechanisms at work in this could lead to even higher efficiency achievements. “Noticeably increased PL intensity, carrier lifetime >650 ns, and increased [open circuit voltage] indicate that the CuxAlOy buffer reduces recombination at the back interface,” the group stated. “…Further characterization of the device stacks with back-buffer layer is needed to determine the critical Cu diffusion, electronic process at the interface and bulk, and to better understand the passivation mechanisms.”

These cells were produced in laboratory conditions, and though the researchers did not evaluate the potential cost of their approach, they note that improving efficiency could naturally help to bring down production costs.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.