A new approach developed by researchers at the Max Planck Institute could potentially pave the way for the transition from 2D foil current collectors, which are used in today’s lithium-ion batteries, to fleece current collectors. The innovation could drive the emergence of a new generation of rechargeable batteries with high energy density, faster charging rates, prolonged runtimes, and longer lifespans.

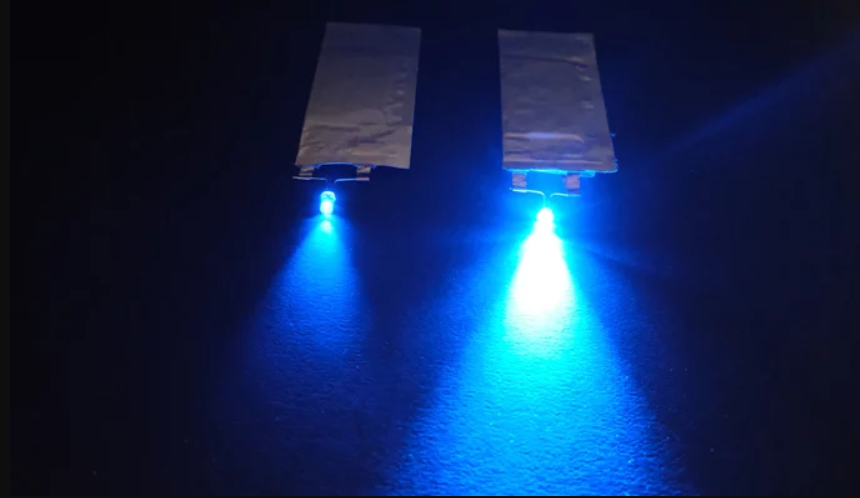

At the heart of the team's innovation is a process developed by Joachim Spatz, the director at the Max Planck Institute for Medical Research. The process results in very fine metallic fibers, which can be used to make thicker battery cells.

The metallic fibers, which have good electrical conductivity, are then processed into a dense, conductive metal mesh and filled with the active material of the anode or cathode. Such electrodes make it possible to increase the thickness of battery cells to more than 2 mm, or 10 times that of cells commonly used today.

The active material, which is important for energy storage, currently accounts for just 60% of lithium-ion battery weight. But the new design developed at the Max Planck Institute for Medical Research reduces the metal content and increases the active material proportion of the total battery weight.

The metal meshes have a significantly larger surface area than conventional current collectors, so the batteries with such current collectors can be charged and discharged much faster. In addition, the metal mesh is said to make the lithium-ion batteries safer by reducing the electrical resistance of the electrodes and increasing their mechanical stability, eliminating unfavorable hotspots in heat generation, as well as electrical and mechanical stress.

The researchers said the new batteries are resource efficient due to “significantly reduced material consumption and an extremely energy-saving manufacturing process.” The millimeter-thick electrodes are said to translate into significantly extended battery life and up to 30% less material costs per kilowatt-hour.

The active material and the batene fleece, as the current collector, are highly elastic and capable of adapting to volume changes during charging and discharging. This reportedly prevents the premature aging of the battery.

While the innovation can function as a drop-in technology for existing production lines, according to the researchers, it is not limited to the lithium-ion batteries of today. The ultra-fine metal mesh electrodes are also said to have great potential for other battery chemistries, such as lithium metal solid-state batteries or sodium-ion batteries.

Batene GmbH, a newly established spinoff of the institute, has licensed the technology through the Max Planck Society’s central technology transfer company, Max Planck Innovation, and is now marketing it. It has already secured initial funding of €10 million.

The startup has also exclusively licensed the corresponding rights to develop and market the technologies. Following successful demonstrators, it is now ready to build up a larger production capacity for electrodes made of metal fleece, to further develop the technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Thicc v. rolled, hooray! Why would it burn brighter without raising cell voltage?

Ooh, I need some batene fleece slippers to get me through spring. Too bad it’s too fine and there’s no tanned batene hide attached. Also pouring molten lithium and solid electrolyte on my feet was a bad idea.