Compared to ubiquitous lithium-ion technology, lithium-sulfur batteries have the potential to offer cheaper, lighter-weight energy storage, as well as cost and safety advantages. Yet the widespread use of these batteries faces hurdles that stem mainly from the limitations in the lifespan of lithium-sulfur cells.

In a bid to bring this technology closer to commercialization, Australian listed company Li-S Energy has announced the development of its first 20-layer battery cells utilizing third-generation (GEN3) semi-solid state lithium sulfur battery technology.

Li-S Energy has been working with Victoria’s Deakin University and PPK Group, among others, to develop the new battery cells, which eliminate the heavy metals like nickel, cobalt and manganese used in lithium-ion batteries.

Li-S Energy’s cell is said to offer volumetric energy density of 540 Wh/l, gravimetric energy density of more than 400 Wh/kg and enhanced safety with the use of a low flammability electrolyte.

The GEN3 battery cell has major advantages over the second-generation iteration, including a 45% increase in volumetric energy density thanks to the use of a lower-porosity cathode material.

Compared to current Li-ion cells, this performance is nearly double the gravimetric energy density and a comparable volumetric energy density. This means that Li-S Energy’s battery cells are now the same size as existing Li-ion batteries but half the weight, the company claims.

Popular content

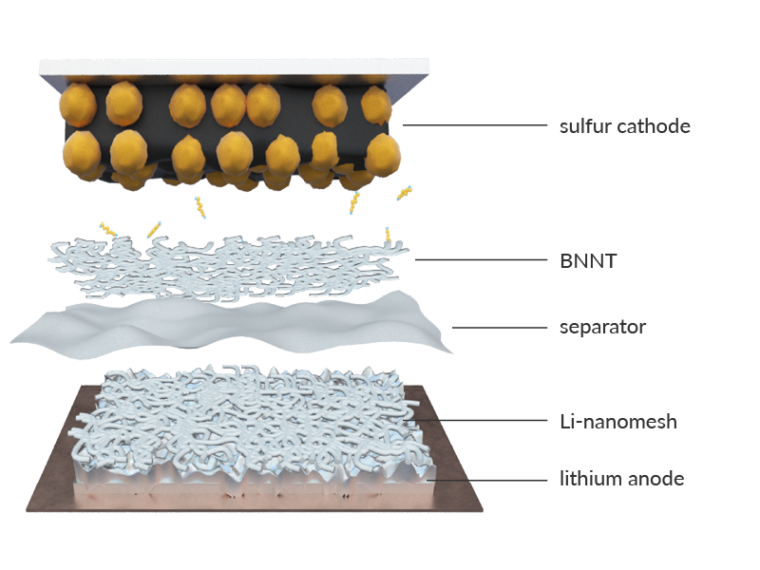

The 20-layer cells use Li-S Energy’s patented Li-nanomesh technology and incorporate boron nitride nanotubes (BNNTs) into the cell construction to reduce dendrite growth and improve safety and cycle life. Test cells have demonstrated sustained performance over 1,000 charge-and-discharge cycles while retaining a specific capacity almost three times that of a typical lithium-ion cell.

The new cells were produced in Li-S Energy’s Phase 2 facility in Geelong, Victoria, where test cell production is anticipated later this year, once the company’s Phase 3 facility is complete. Phase 3 is a 2 MWh production line, which will enable more automated production and include what is potentially the largest dry room in Australia.

“In the coming months we look forward to commencing the production of commercial samples for our partners,” says Li-S Energy CEO, Lee Finniear.

At this point, the Li-S Energy development team is working to develop the cell cycle testing and characterization results to produce an industry standard datasheet on the new 20-layer cells.

Li-S Energy has identified electric aviation and drones as key sector where it has a competitive advantage due to the light weight of its batteries. In 2022, the battery start-up inked a deal with U.S.-based e-aviation company magniX, which will test the potential of the company’s technology for e-aviation applications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.