Using heat pumps to preheat industrial hydrogen (H2) systems could reduce the need for H₂ by more than 20% and lower the cost of process heat for heavy industry by more than 10%, according to new research from the United Kingdom.

The group of researchers, led by the University of Leeds, claims that utilizing heat pumps to preheat hydrogen to very high temperatures could reduce European industry demands by approximately 200 TWh per year, with a reduction of 40 TWh per year in the UK alone.

In the study “Reducing industrial hydrogen demand through preheating with very high-temperature heat pumps,” published in Applied Energy, the scientists said their findings stem from recent developments in the field of thermo-mechanical energy storage, which enable heat pumps to operate at very high temperatures.

“Heat pumps have typically been considered for low-temperature applications in buildings, district heating, and industry, with maximum temperatures of up to around 75–100 C,” the study notes, adding that combining heat pumps with thermal energy storage has enabled scientists to reach an operating temperature of 500 C with argon as the working fluid.

The researchers said that, while heat pumps are for now far from reaching the extreme temperature required for many industrial heat processes, such as blast furnaces, they can be harvested to preheat combustion air or hydrogen. The article assessed the performance of preheating to temperatures of 300–500 C, and found better cost savings in the higher point.

“For a given combination of electrolyzer capex and electricity price, the relationship between relative cost saving and temperature is found to be linear over the 300 C to 500 C temperature range,” they said. “Adding a reverse Joule-Brayton heat pump to a green hydrogen-based heating system provides cost savings when electricity prices exceed around GBP5 ($6.35)/ MWh. At electricity prices above GBP30/MWh and electrolyzer costs above GBP400/kW, cost savings exceed 5% when preheating to 300 C and 8% when preheating to 500 C.”

Popular content

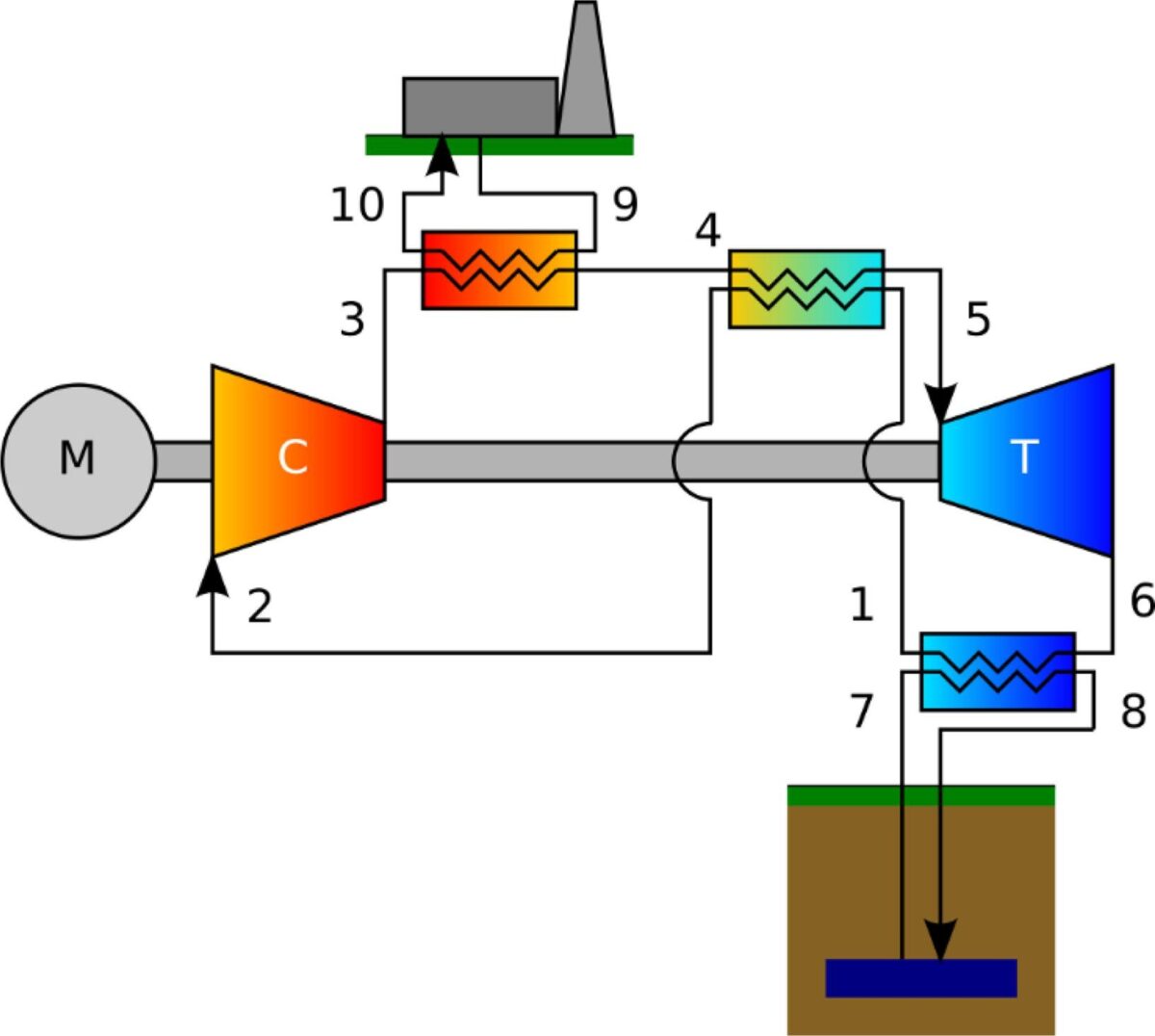

Heat pumps based on the reverse Joule–Brayton cycle are commonly utilized for small-scale applications. They usually draw ambient air into a compressor and then convey the hot compressed air into a heat exchanger where it is cooled, thereby delivering heat to a radiator circulating water or a hot water system. Finally, it expands the air through a reciprocating expander to atmospheric pressure and pushes it out to the atmosphere.

The scientists explained that the cost-saving ensured by this heat pump system is possible partly by the fact that heat pumps absorb heat from the environment and therefore reduce electricity demands. In the proposed system configuration, the group assumed that the heat pump transfers heat from a water source such as mine water to an industrial plant. More cost saving is related to the use of less fuel, hydrogen in this case, that is made possible by its preheating.

“Heat pumps appear to be a lower cost preheating option than electric boilers at electricity prices above around GBP25/MWh, with levelized cost savings on the electric boiler option reaching approximately 4% at electricity prices above GBP130/MWh,” the academics explained. “However whether the savings from using heat pumps outweigh their added complexity requires further investigation and should be considered on an application-specific basis.”

They said their work might help decarbonize the world's economy, as process heat that can utilize heat pumps accounts for around 11% of global energy demand.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.