Scientists from Spain’s research center Tecnalia have encapsulated solar panels with a composite material that they claim has enhanced chemical recyclability.

The novel encapsulant material is based on glass fiber-reinforced composite material with an epoxy matrix containing cleavable ether groups. “The aim was to provide the encapsulating material and PV modules with enhanced chemical recyclability while retaining photovoltaic performance and durability,” the research group explained. “Further work will consider improving the moisture barrier properties of the composite, and adjusting the recycling conditions to allow component recovery valid for new modules.”

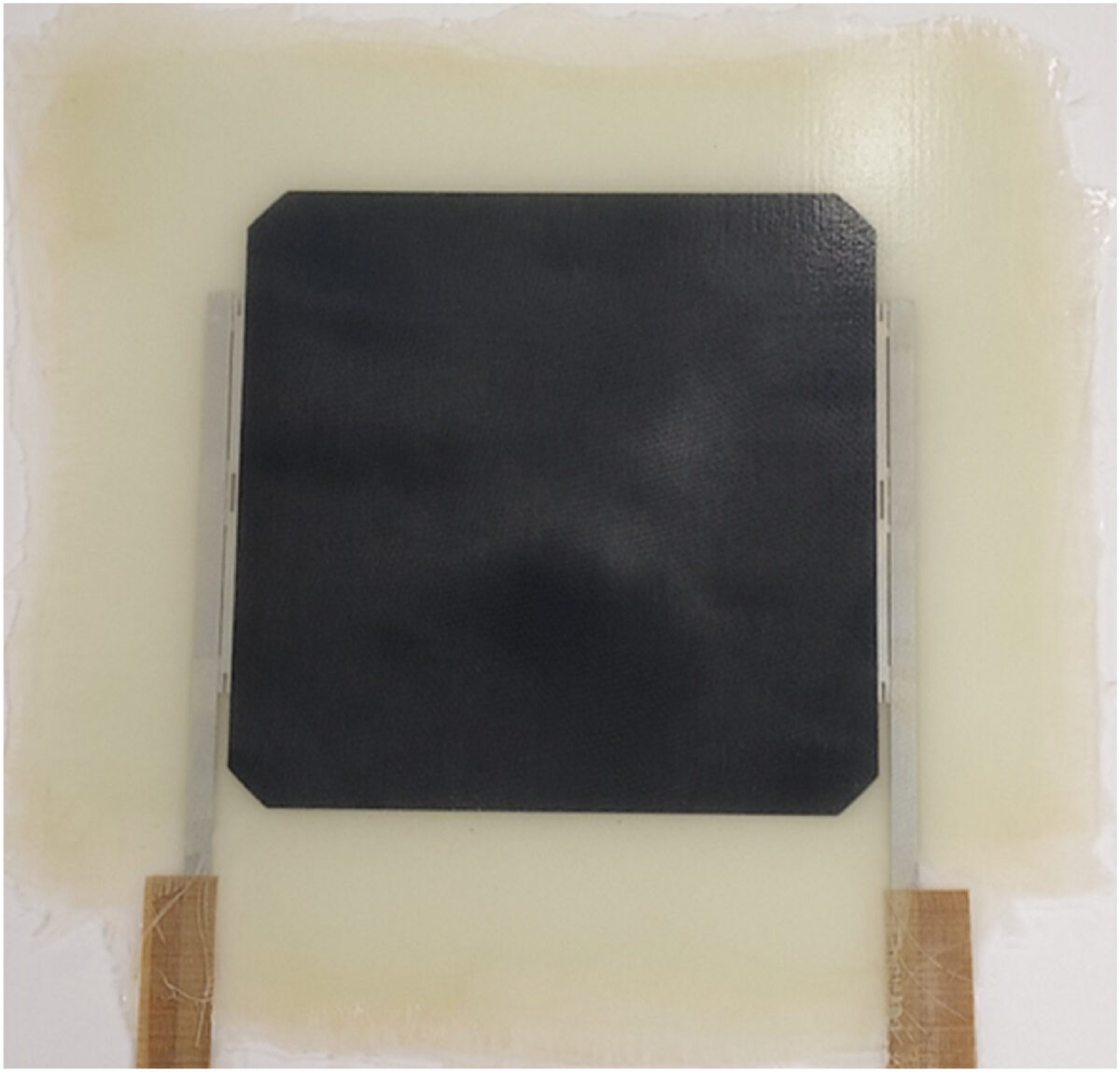

The researchers fabricated twelve solar module samples using monocrystalline silicon cells and encapsulated them with the new material using a linear vacuum resin infusion process. “As reinforcement, a glass fiber fabric with a 300 g/m2 (0/90◦) areal weight was used. The reinforcement layout consisted of 3 layers placed at the front and back of the cell. As a composite matrix, an epoxy resin system with amine base hardener and cleavable chemical groups in its composition was used,” they noted.

The group tested the performance of the panels and compared it to reference modules encapsulated with a standard resin system based on a clear bisphenol-A epoxy and an amine-based crosslinker. In the set of tests, the recyclable encapsulants were tested against the reference encapsulant, as well as bare solar cells without any kind of encapsulation.

“The data of the monomodules with the composite encapsulant based on the recyclable epoxy resin showed an electrical loss in short-circuit current of 6.3% when comparing the electrical performance before and after encapsulation,” the researchers said. “This value was slightly lower than the one obtained for the monomodules with standard epoxy composite, which presented a decrease of 7.2%.”

The group observed a similar trend when analyzing the power at maximum point (Pmp) losses and the external quantum efficiency (EQE) spectra, a metric for the efficiency and spectral response of photovoltaic devices.

Popular content

The researchers also conducted a damp-heat test for 500 hours of exposure on the panel encapsulated with the new material, and found it showed an electrical loss in short-circuit current of 3.4%, which compared to only 1.5% for the benchmark panel.

“After 1000 h exposure, the observed short-circuit current decrease was even more pronounced, being significantly higher for the cleavable epoxy matrix,” the academics noted. “A final loss of 4.9% was measured for recyclable resin, whereas the standard epoxy showed a lower value of 2.8%. Regarding Pmp values, the loss reached 4.7% and 3.4% for the recyclable and standard composite respectively.”

In addition, the researchers carried out stability and aging tests for UV exposure and thermal cycling. As for the latter, it presented a loss of around 1% in short-circuit current and Pmp, which is not considered significant, as it is below the measurement accuracy of the technique. As for the UV exposure, electrical losses were also close to 1%.

The novel material was described in the paper “Composite material with enhanced recyclability as encapsulant for photovoltaic modules,” published in Heliyon.

Looking ahead, the researchers noted future work needed in both analysis and improvement of surface homogeneity, as well as studying the aging performance of the modules made with the recovered fibers, and possibly using a different resin-fiber interface. Additionally, the researchers see opportunity to improve the proposed technology. “Future work will also be focused on improving the damp-heat stability of the composite, in a trade-off with a successful recyclability,” they stated.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.