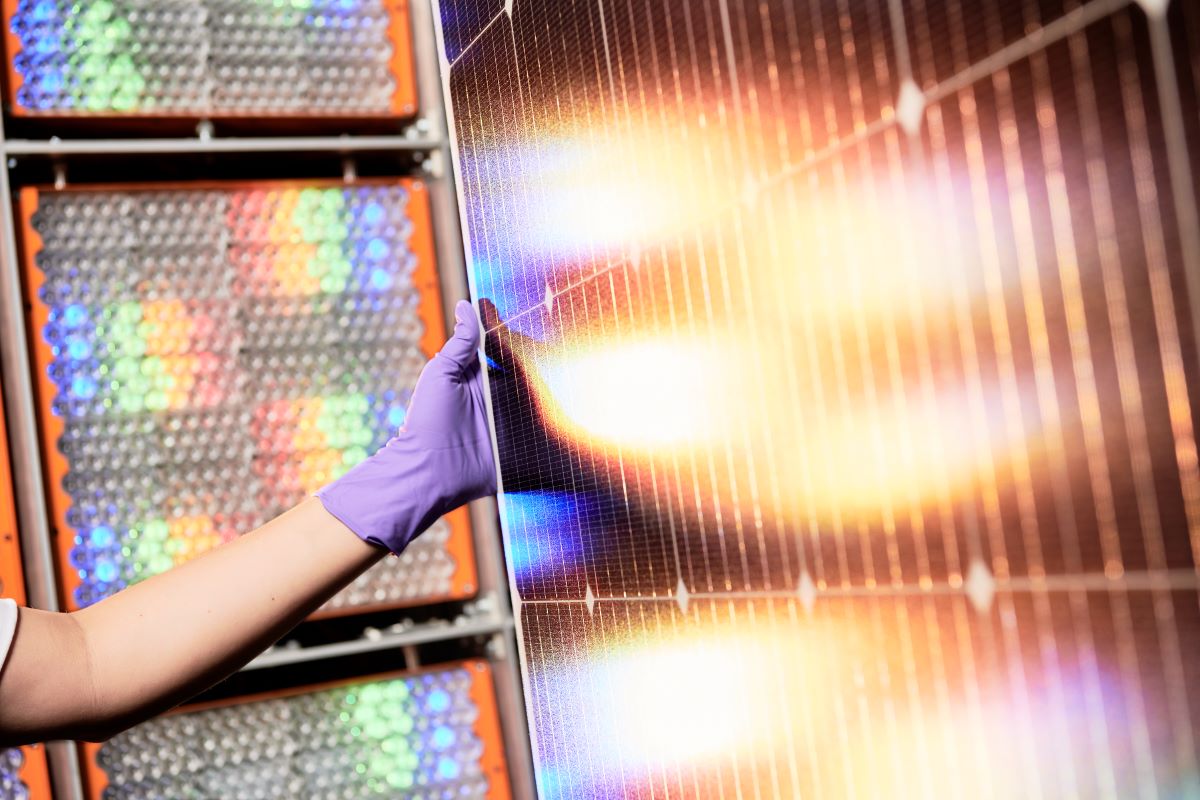

Germany’s Fraunhofer ISE has fabricated a perovskite-silicon tandem solar module with a glass-glass design.

The panel has a power conversion efficiency of 25% and an output of 421 W. It measures 1.68m2 and uses cells produced by Oxford PV, a UK-based perovskite solar cell manufacturer with pilot production in Germany. Oxford PV says that the module was assembled by the Fraunhofer team using its specifications.

“This new world record is a crucial milestone for Oxford PV, proving that our tandem solar cells can deliver record-breaking performance when assembled into solar panels,” Oxford PV CEO David Ward said in a statement.

The tandem cells produced by Oxford PV are M6-format. Last year, the company broke a record with a verified cell efficiency of 28.6 %. The tandem cells are currently produced in a small series line in Brandenburg, Germany, with commercial production slated for later this year.

The researchers said they utilized commercially available PV production equipment installed at the Fraunhofer Module Technology Evaluation Center (Module-TEC) and optimized the processes to make the glass-glass modules. “The fact that mass production-compatible technology was used for its manufacture demonstrates the enormous potential of tandem technology for the PV industry,” said Stefan Glunz, head of PV at Fraunhofer ISE.

The solar cells were interconnected using conductive bonding equipment at Fraunhofer ISE's Module-TEC. As the perovskite layer of the tandem cells is temperature-sensitive, the research team said it had to develop low-temperature processes for the interconnection and encapsulation of the solar cells.

Popular content

“In the future, we will also be testing another alternative: soldering the solar cells at low temperatures,” said Achim Kraft, who heads up the interconnection technology group at Fraunhofer ISE. “These are suitable for industrial mass production and can be implemented on commercial systems. The necessary adaptions can also easily be implemented in today’s PV production lines”

For the calibration measurements, the Fraunhofer ISE tapped its well-equipped calibration lab to determine the module efficiency, noting that precise and reproducible statements about the tandem module’s power, are only possible if both the perovskite and the silicon cell layers are illuminated by appropriate LED light sources under conditions as close as possible to natural sunlight.

“As the currently standardized measurement methods are not fully transferable to this new technology, the method used was additionally validated with field measurements,” noted the researchers.

The project teams from Fraunhofer ISE and Oxford PV are now working towards certification of the PV module and tests on long-term stability.

This article was amended on 31.1.2024 to reflect that the module was assembled by Fraunhofer ISE using cell technology and module specifications from Oxford PV. And to amend typo that transposed numbers for verified efficiency of cell to the corrected 28.6%.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

5 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.