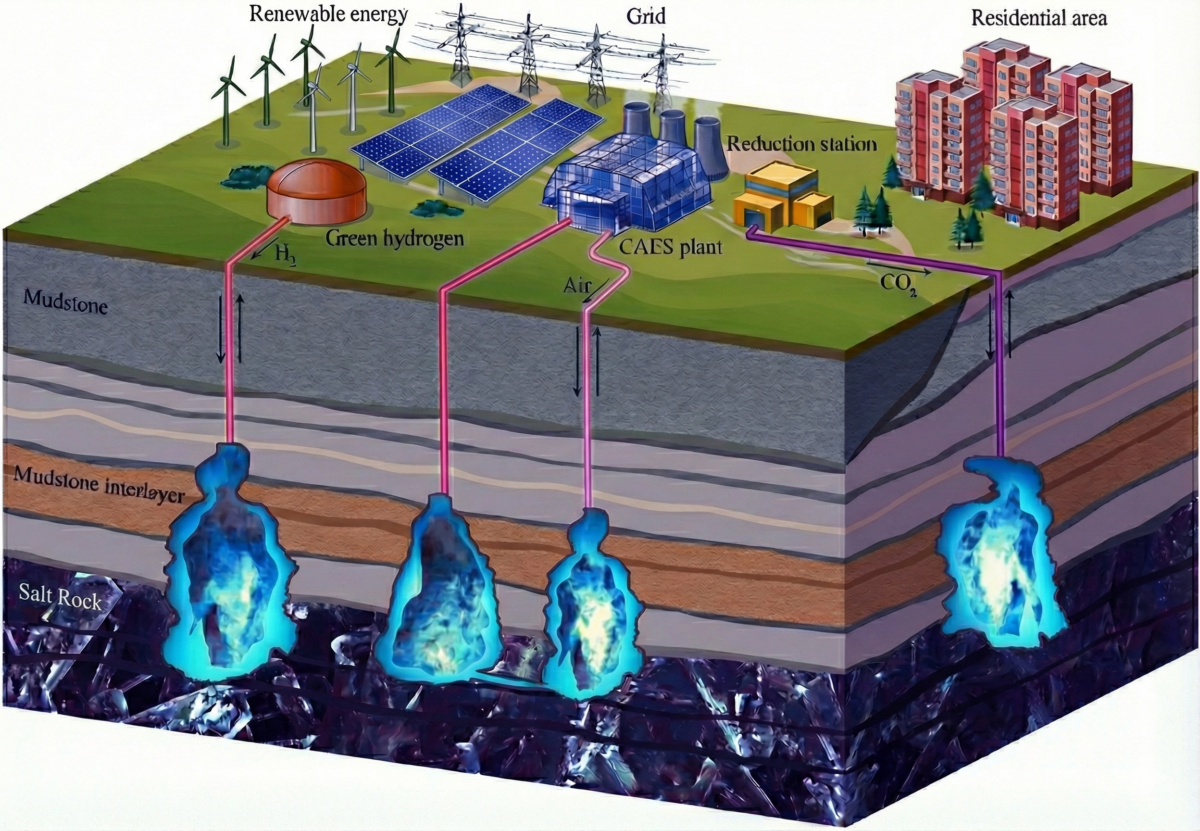

A research group from China has investigated the long-term stability of using two-butted-well horizontal (TWH) located in low-grade, dipping salt layers for compressed air energy storage (CAES).

“According to statistical data, approximately 85% of the existing salt caverns in China are TWH,” the research team explained. “As salt cavern energy storage reservoirs expand, high-quality caverns with favorable geological conditions are becoming increasingly scarce. China hosts numerous TWH salt caverns with high sediment content—some reaching up to 90% or even being completely buried. Therefore, research on low-grade inclined salt layer TWH caverns holds critical engineering significance.”

The study is based on a simplified version of a TWH in Qianjiang City, located in the south-central region of Hubei Province, China. The shape of the salt cavern used for CAES was modeled as an ideal ellipsoid, with a length of 800 m, a width of 300 m, and a thickness of 800 m. The long axis radius of the ellipsoid is 100 m, the short axis radius is 40 m, the diameter of the connecting channel is 15 m, and the height of the salt cavern is 200 m. The total thickness of the salt layers and interlayers is 286 m, of which the salt layers account for 190 m.

Based on the characteristics of the Qianjiang Salt Mine, the academics investigated the effects of burial depth at five distinct roof depths: 500 m, 800 m, 1,200 m, 1,600 m, and 2,000 m. In addition, the group investigated dip angles of 7.5°, 15°, 20°, 25°, and 30°. The dip angle is the angle at which a rock layer is tilted relative to the horizontal. A larger dip angle means the layer is steeper, so one side of a cavern sits deeper and carries more weight than the other.

The CAES was simulated to operate for 30 years, with 8 hours of charging and 5 hours of discharging per day.

The group has selected four evaluation criteria for the long-term stability of CAES salt caverns at different depths and angles: volume shrinkage rate (VSR), plastic zone volume (PZV), maximum surrounding rock displacement (Dis-Max), and safety factor (SF). VSR quantifies the relative loss of cavern volume over time due to salt creep, whereas PZV denotes the volume of surrounding rock that has entered irreversible deformation. Dis-Max measures the maximum displacement of the surrounding rock at any point around the cavern, whereas SF denotes the distance between the current stress state and the onset of failure in the salt.

“The results indicate that the salt cavern VSR and Dis-Max increase exponentially with depth, with a notable accelerating growth after exceeding 1,500 m,” the team noted. “An increase in formation dip angle exacerbates asymmetry in VSR and displacement in the lower cavern. For every 10° increase in dip angle at 2,000 m depth, VSR and Dis-Max increase by 3.53 % and 489 mm, respectively. The sediment body exhibits a significant buffering effect on surrounding rock deformation, and its VSR is less affected by dip angle.

In conclusion, they proposed that for deep salt caverns at depths of 1,500 m or greater, priority should be given to controlling the dip angle to 20° or less, whereas for shallow caverns at depths below 1,000 m, the allowable dip angle could be relaxed to 30°. They further stated that the study offers important reference guidance for the construction of compressed air energy storage facilities in dipping salt layers that are widely distributed across China.

Their findings appeared in “Stability evaluation of horizontal connected salt cavern compressed air energy storage in low-grade dipping salt layers,” published in Earth Energy Science. Scientists from China’s Chongqing University, SINOPEC Petroleum Exploration and Production Research Institute, the Ministry of Natural Resources’ Key Laboratory of Unconventional Natural Gas Evaluation and Development in Complex Tectonic Areas, and the Guizhou Engineering Research Institute of Oil & Gas Exploration and Development Engineering participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.