10 GW Desert to Power PV initiative picks up $150 million in funding

The Green Climate Fund has announced it will provide US$150 million in funding to the Desert to Power initiative – a project led by the African Development Bank and spanning several countries that aims to build 10 GW of PV generation capacity in various projects across the Sahel region to the south of the Sahara Desert.

Portugal completes 219 MW unsubsidized PV project

Ireland-based WElink Group and China Triumph International Engineering Co. Ltd have announced the completion of the 219 MW Solara 4 project in Portugal’s Algarve region. An inauguration ceremony for the project was held last week, and it is expected to begin full operations before the end of October.

Reliance Industries acquires 100% stake in REC Group, plans new manufacturing bases

India headquartered multinational Reliance Industries, through its subsidiary Reliance New Energy Solar Limited, yesterday announced the acquisition of Norway headquartered module manufacturer REC Group. The move comes as Reliance pushes forward with its US$10 billion plan to move in on the renewable energy industry, having also this week announced acquisition of a 40% share in EPC provider Sterling & Wilson.

Reliance Industries’ new energy arm to acquire 40% stake in Sterling and Wilson Solar

The acquisition gives Reliance New Energy Solar access to Sterling and Wilson Solar’s PV plant engineering and project management skills as it aspires to become a global leader in green energy based on the latest and most cost-competitive technologies and development capabilities.

Fortescue Future Industries to build 2 GW hydrogen electrolyser plant in Australia’s Central Queensland

From iron ore magnate to renewable energy mogul, Dr. Andrew ‘Twiggy’ Forrest intends to produce everything he needs to turn the world away from fossil fuels to green hydrogen. The latest? A renewable energy infrastructure manufacturing facility in Aldoga, near Gladstone in Central Queensland.

The weekend read: Half-cut solar cells on edge

Half-cut solar cells have quickly grown to become an industry standard, promising more power through reduced cell-to-module losses, among other advantages. Innovative processes have been introduced to reduce cell damage during the actual cutting process, but even these still leave behind an unpassivated area at the edge of the cell, which can result in performance losses. As cell efficiencies increase, this will only become more of a problem. pv magazine examines the possible solutions.

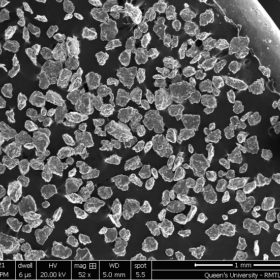

The Hydrogen Stream: New magnesium-based composite for hydrogen storage and a big push from South Korea

Researchers at Canadian Nuclear Laboratories (CNL) identified a new magnesium-based alloy that could be used for hydrogen storage. Furthermore, Hyundai Mobis announced a $1.1 billion (€0.95 billion) investment in two new fuel cell plants in South Korea, while South Korea’s SK Group formed a joint venture with US hydrogen solutions company Plug Power to develop green hydrogen across several Asian countries.

Chinese PV Industry Brief: New solar glass production lines and a new big wafer deal

Luoyang Glass is planning to deploy two solar glass production lines with an annual capacity of 1,200 tons each and wafer maker Wuxi Shangji has secured a big supply agreement from Longsheng New Energy. Furthermore, Tongwei has reported increasing profits driven by its polysilicon business.

Maxeon refurbishes Mexican factory to set up 1.8 GW module manufacturing hub for US market

The Singapore-based manufacturer operates two factories in the Baja California state bordering the United States and the entire output of the facility in Mexicali will be shipped exclusively to the US market. Furthermore, the company’s chief revenue officer, Mark Babcock, told pv magazine that a manufacturing facility is also being considered in the US.

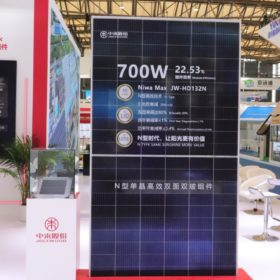

Jolywood unveils 700 W TOPCon PV module

The double-glass product has dimensions of 2,384 x 1,303 x 35 mm and a weight of 38 kg. It is based on the company’s n-type TOPCon 2.0 cell technology dubbed Niwa Max, which the manufacturer said reached efficiencies of up to 25.4% in the laboratory. The module’s efficiency ranges from 21.73 to 22.53%.