Raising the efficiency of polycrystalline cells with new luminescent EVA film

Chinese researchers have developed a pure EVA film, which they claim can enhance the conversion efficiency of conventional crystalline solar cells by around 0.50%. The film is able to convert UV light into strong visible light.

How much can you wash a wearable PV device?

UK researchers claim to have proved the viability of wearable photovoltaic devices as an integrated part of regular clothing. A solar-powered fabric textile was created by embedding micro-crystalline silicon solar cells within the fibers of a textile through thin copper wires. The scientists claim that the device can maintain its performance even after 15 domestic machine cycles, 25 hand wash cycles, and 6000 abrasion cycles.

A new approach to performance simulation of heterojunction III-V solar cells

Scientists from Italy are proposing a new theoretical approach based on the combination of the scattering matrix method (SMM) with the Hovel method. The new model is said to describe with improved accuracy the propagation of electromagnetic waves in solar cells based on indium gallium phosphide (InGaP), indium gallium arsenide (InGaAs) and germanium (Ge), taking into account the interference effects. In their view, with proper antireflective coating III-V solar cells can reach efficiencies of more than 50%.

The weekend read: The rise of M6

The shift to the larger M6 wafer format could occur faster than many have expected. Promoted heavily by mono giant Longi, the format is said to be a good fit for both cell and module production, while still allowing for relatively trouble-free integration into PV arrays. And it all began in China.

India’s solar cell and module exports grow 157% in eight months

Following a dip in the last fiscal year, the value of cell exports saw a massive surge to an estimated INR13.3 billion from April to November. Exports to the U.S. tripled during the eight-month period as shipments to Turkey and Belgium rebounded to become the next two biggest export markets.

New process could yield 26.6% efficient IBC cells

Researchers in Germany are trialing a host of new processes and materials to develop interdigitated back contact solar cells. A deposition technology named ‘hot-wire’ chemical vapor deposition, is said to provide excellent passivation without the need for treatments such as recrystallization or hydrogenation.

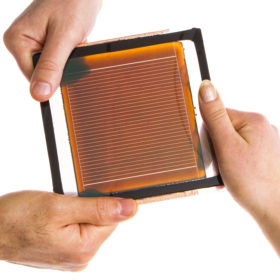

Deal reached to keep Energyra module production in the Netherlands

The Dutch PV manufacturer plans to start production this year after a last-minute rescue package arrived as the company’s equipment was being auctioned off.

Perovskites meet the stability standard

European research group Solliance says its perovskite modules have passed three key industry standard reliability tests: Light soaking, damp heat and thermal cycling. The group said it is the first time perovskite modules of that size have achieved such results and represents a milestone in the technology’s move toward commercialization.

‘China will add 35-38 GW of solar this year’

Power generation statistics released by the National Energy Administration appear to confirm the nation added 12 GW of solar last month. China also deployed another 41 GW of polluting coal-fired power plants last year.

Lead-free soldering in modules: It can be done!

pv magazine’s UP sustainability campaign has investigated the use of lead in PV panels and found, with soldered cell interconnections in particular, viable alternatives are scarce. However, German headquartered manufacturer Opes Solutions has launched a small module for the off-grid market featuring lead-free solder, developed at the request of a customer. We caught up with Opes CEO Robert Händel for a closer look at the module and the challenges and benefits of going lead-free.