Titanium makes perovskite solar cells more durable

After finding a way to make spiro-OMeTAD, a popular perovskite solar cell hole transport layer, less prone to heat-induced crystallization, researchers at Georgia Institute of Technology are now seeking partners to scale the technology for large-area PV cells.

Polysilicon market unchanged, awaits policy stimulus

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

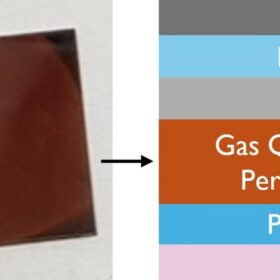

Gas quenching with helium, argon for more stable perovskite solar cells

Kuwait University researchers investigated the relationship between the molecular weight of the quenching gas and the morphology of perovskite films used in solar cells, finding that argon and helium extended device lifetimes compared to using the more conventional nitrogen.

Corning, Suniva, Heliene to produce first fully US-made solar module

Corning, Suniva and Heliene are combining their strengths to produce what will be the first solar module with polysilicon, wafers and cells made in the United States.

Longi unveils anti-dust back contact solar module with 24.8% efficiency

Longi has released a back-contact solar module with 24.8% efficiency, featuring a power output of up to 670 W and a temperature coefficient of -0.26% per degree Celsius.

UtmoLight pushes perovksite PV module efficiency to 18.1%

UtmoLight has reached 18.1% efficiency with its perovskite PV modules, according to results confirmed by the US National Renewable Energy Laboratory (NREL).

US solar facilities lost $5,720 per MW to equipment issues in 2024

US solar facilities lost $5,720 per megawatt in 2024, with global losses from equipment failures and extreme weather reaching $10 billion. Raptor Maps says 193 GW of projects recorded rising power losses, primarily from inverters, strings, and combiners, with regional weather risks varying significantly.

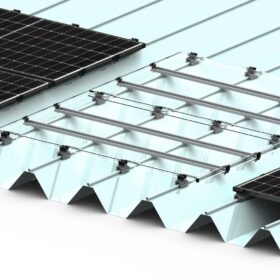

Trina, Daidohant launch new load-bearing mounting solution for heavy snowfall

The Chinese manufacturer has collaborated with Japan’s Daidohant on the new product. It reportedly suppresses deformation with a special bar attached to the back of the solar module.

Tandem PV moves toward perovskite manufacturing with $50 million funding

With a perovskite layer 200 times thinner than silicon and requiring just 10% of the energy needed to produce conventional panels, Tandem PV reports it will be able to reduce energy use during manufacturing.

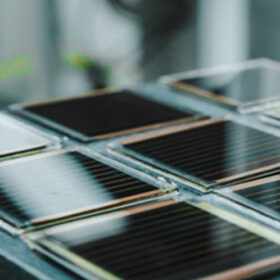

Chinese scientists build 20.3%-efficient mini inverted perovskite solar modules via slot die coating

A team led by University of Electronic Science and Technology of China (UESTC) has found that pyrrodiazole as an additive in formamidinium iodide (FAI)-based inverted perovskite solar enables larger area devices made with industry-compatible slot die coating. Modules made using the technology achieved 20.3% certified power conversion efficiency and retained 94% of initial efficiency after 1,000 h in standard testing.