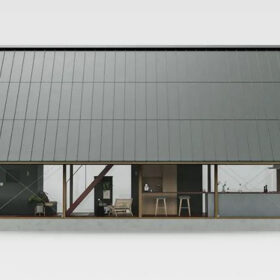

Itoki, Hitachi, Tokuyama recycle solar glass for office furniture

The Japanese companies have used their unique technologies to demonstrate how glass from end-of-life PV panels can be used in office furniture components, specifically in an office privacy cabin.

NEDO outlines R&D concepts to expand solar adoption in Japan

Japan’s New Energy and Industrial Technology Development Organization (NEDO) has launched a 2025–29 project with 24 themes to advance the development of next-generation solar cells, site-specific systems, grid stability, and recycling in line with its carbon neutrality goal.

Panasonic testing new energy management system to combine solar, heat pumps, batteries

The Japanese company said the first pilot projects are being carried out in the Tokyo metropolitan area with the support of Japanese oil giant Eneos.

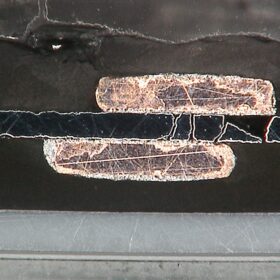

Investigating solar glass quality for recycling in new glass products

A team of Japanese scientists explored how typical PV panel component materials affect the ability to re-use end-of-life PV cover glass. Specifically, they measured contamination by materials, such as aluminum, silicon, carbon, and copper, and their effects in melted PV panel glass cullet.

Japanese startup debuts silver-colored BIPV solar module

The new product weighs 13 kg/m2 and is claimed to be particularly suitable for building facades. It features a power ouput of 75 W and a junction box with an IP-68 rating.

All back-contact perovskite solar cell designs at a glance

Scientists from Japan, Saudi Arabia and the United States have investigated existing back-contact perovskite solar cell architectures and have proposed a strategy to help reach commercial production.

How to measure solar cell vibrations in vehicle-integrated photovoltaics

Researchers at the University of Miyazaki in Japan used a new non-destructive method to enable them to investigate solar cell vibrations independently of module components. The study included potential design features for resonance-resistant vehicle integrated PV modules that would increase the natural resonance frequency to above 2,000 Hz.

Japan to launch platform linking aggregators with FIP operators

Japan plans to launch an online platform by September 2025 linking aggregators with feed-in premium (FIP) operators to support grid integration, streamline solar battery installations, and improve planning and forecasting for renewable projects.

Suzuki venture starts electrode output in India

Japan’s Toshiba, Denso and Suzuki have launched local lithium battery cell and electrode production in India through their TDSG venture, supplying hybrid and electric vehicles for global markets.

Sumitomo Heavy unveils reactive plasma tech for thin-film perovskite PV

Sumitomo Heavy Industries (SHI) has developed a new reactive plasma deposition (RPD) method to form ultra-thin tin oxide electron transport layers (ETL) for perovskite solar cells. It claims this enables low-temperature mass production with minimal substrate damage.