Sembcorp builds 360 MW battery in the UK

Once deployed, the battery will be Europe’s largest storage facility.

Australia switches on new storage battery

Neoen has started operating a 300 MW/450 MWh big battery in Geelong, Australia. In spite of a fire during commissioning in July, the battery has been delivered in record time, taking less than a year to build and begin operations.

Fast charging for lithium-ion batteries needs a fix

Scientists in the United States placed fast charging for lithium-ion batteries under the microscope, finding that charging at higher rates can quickly damage the structure of a graphite anode, causing capacity loss even after a small number of cycles. By identifying the mechanisms causing this performance loss, the group can help point future research in the right direction.

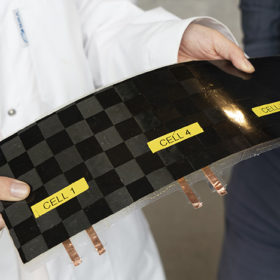

Massless battery for applications in vehicle-integrated solar

Swedish scientists have developed a structural battery that purportedly offers “massless” storage, as its weight vanishes when it becomes part of the load-bearing structure. The device has an energy density of 24 Wh/kg and is designed for easy integration into solar-powered vehicles.

MIT scientists develop semisolid zinc-manganese dioxide flow battery for wind, PV storage

MIT researchers have created a semisolid flow battery that might be able to outperform lithium-ion and vanadium redox flow batteries. It features a new electrode made of dispersed manganese dioxide particles shot through with an electrically conductive additive, carbon black.

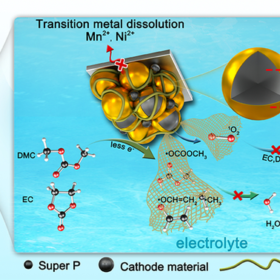

New ‘bioinspired’ solution to battery degradation

As part of their efforts to bring lithium-ion battery degradation under control, scientists in China have looked to emulate natural defenses many organisms have evolved to reduce oxidation reactions and related damage. With an additive that ‘scavenges’ reactive particles before they can contribute to degradation, the group was able to demonstrate significantly lower electrolyte decomposition in a working battery.

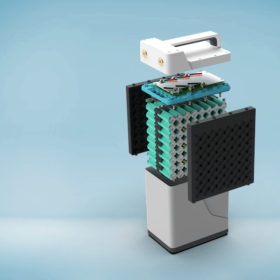

Centipede battery energy storage launched by Powin

The battery features a modular design with pre-integrated segments that contain batteries, thermal management, and safety systems. The design offers scalability and supports up to 200 MWh storage per acre.

Canadian mining company acquires 10 vanadium sites in Morocco

Canada-based Elcora said the transaction will enhance its mining operations and energy storage business.

Behind the price drops in lithium-ion batteries

Scientists in the United States pieced together data from hundreds of different sources, looking to establish the key factors that have led to consistently falling prices for lithium-ion technology since their commercialization thirty years ago. They find that public-funded research, primarily in chemistry and materials science, has made the largest contribution to cost reduction. And they offer suggestions on policy and investment to ensure that the research can continue to make these important contributions to reduction in battery costs.

UK business claims to offer ‘world’s most sustainable lithium-ion battery’

English manufacturer Aceleron claims every component of its devices can be accessed for replacement, repair or recycling, with the business’ co-founder stating the aim is to ensure ‘100% of the materials in our batteries will continue to be used for as long as possible – preferably forever.’