German researchers develop recycling for dry-processed Li-ion batteries

Researchers at the University of Münster have developed a mechanical recycling process for production scrap from the dry processing of lithium-ion batteries. The method operates without solvents, preserves material properties, and allows the recycled cathode powder to be directly reused in electrode manufacturing.

China’s REPT Battero to build battery factory in Indonesia

China’s REPT Battero has revealed plans to build a lithium-ion battery plant in Indonesia, targeting 8 GWh of annual production capacity in the first phase.

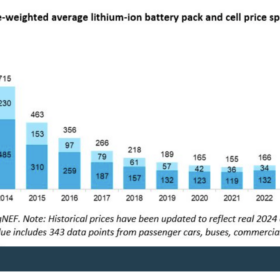

BNEF: Lithium-ion battery pack prices drop to record low of $115/kWh

Battery prices continue to tumble on the back of lower metal costs and increased scale, squeezing margins for manufacturers. Further price declines are expected over the next decade.

Researchers develop lithium-sulfur battery that can be cut, folded

By coating the iron sulfide cathodes in polymers, a research team was able to create transition-metal sulfide-based lithium batteries with stable cycling and high safety. After 300 cycles, a lithium carbide iron disulfide pouch cell retained 72.0% capacity with no capacity degradation after 100 cycles.

Maxvolt secures $1.5 million for lithium battery plans in India

Maxvolt Energy Industries has raised $1.5 million from angel investors to accelerate its lithium-ion battery R&D efforts, enhance production capacity, and expand market reach.

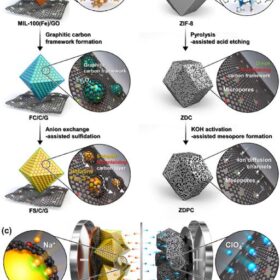

Sodium-ion battery could charge in several seconds

Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have identified a high-energy, high-power hybrid sodium-ion battery capable of charging in just a few seconds. The system integrates anode materials typically used in batteries with cathodes suitable for supercapacitors.

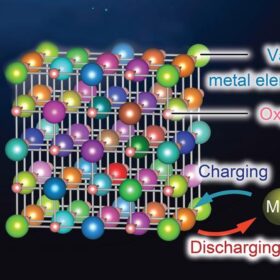

Rechargeable magnesium batteries for grid-scale storage

Researchers in Japan have developed a novel cathode material for rechargeable magnesium batteries (RMBs) in the form of rocksalt oxide. This new material reportedly enables efficient charging and discharging even at low temperatures.

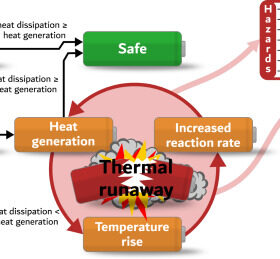

How safe are lithium iron phosphate batteries?

Researchers in the United Kingdom have analyzed lithium-ion battery thermal runaway off-gas and have found that nickel manganese cobalt (NMC) batteries generate larger specific off-gas volumes, while lithium iron phosphate (LFP) batteries are a greater flammability hazard and show greater toxicity, depending on relative state of charge (SOC).

New electrolyte for safer, more stable solid-state batteries

Researchers in Japan have discovered a stable, highly conductive material that can be used as electrolyte for solid-state lithium-ion batteries. The material’s ionic conductivity is said to be higher than any previously reported oxide solid electrolytes, with a wide operating temperature range.

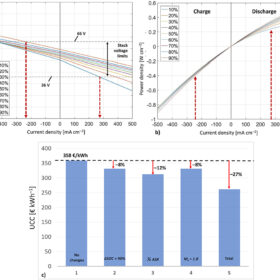

Evaluating the profitability of vanadium flow batteries

Researchers in Italy have estimated the profitability of future vanadium redox flow batteries based on real device and market parameters and found that market evolutions are heading to much more competitive systems, with capital costs down to €260/kWh at a storage duration of 10 hours.