Black perovskite solar cell with 15% efficiency via thermal evaporation

The cell exhibited an open-circuit voltage of 1.1 V and was able to retain around 90% of its initial performance after 215 days of exposure to dim light at room temperature. According to its creators, this performance and the notable stability were ensured by the thermal evaporation technique used for depositing the perovskite layers onto the cell.

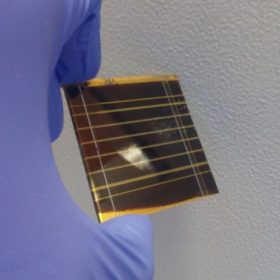

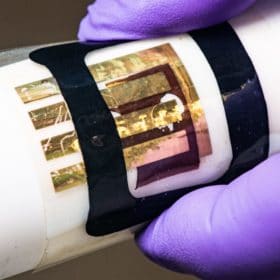

Flexible perovskite solar module with 10.5% efficiency

The methylammonium-free inverted solar module was built on a flexible substrate made of polyethylene terephthalate (PET). A hole transporting material made of poly(triarylamine) (PTAA) and a double-cation cesium formamidinium (CsFA) perovskite layer were deposited through blade-coating and nitrogen-assisted blade-coating.

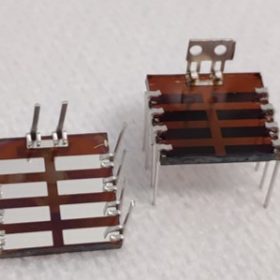

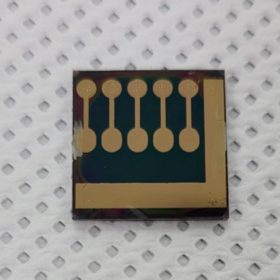

Perovskite solar panel with 16.1% efficiency via ambient air blade-coating

The panel, fabricated by scientists in Italy, is composed of five series-connected cells, each with an area of 2.01 cm² and has an aperture area of 11 cm². It showed a power conversion efficiency of 16.1%, an open-circuit voltage of 5.59 V, a short-circuit current of 37 mA, and a fill factor of 72.5%.

Perovskite solar cell with 19.1% efficiency via CO2 doping

Thanks to a carbon dioxide doping technique, the solar cell interlayers exhibited conductivity around five times higher than that of a perovskite cell based on interlayers doped with oxygen. The device also showed an open-circuit voltage of 1.14 V, a short-circuit current density of 21.2 mA cm2 and a fill factor of 0.79.

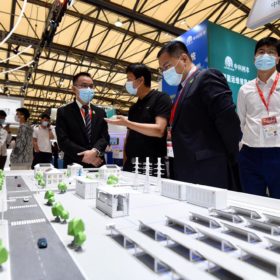

Huawei and Yingli announce smart collaboration

The two brands announced a strategic project at the SNEC solar conference and trade show which will see the establishment of trading and big data centers to help roll-out PV in China.

Swedish perovskite startup picks up new investment

Norway based renewables investor Magnora has increased its stake in startup equipment supplier Evolar, which is aiming to bring a production line for perovskite solar cells to market. Magnora will now hold a 40.7% stake in the company as part of a long-term deal between the two, with options to further increase the stake available down the line.

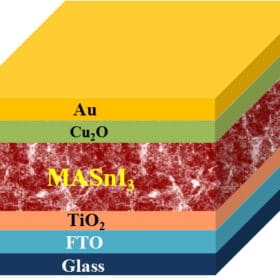

Lead-free perovskite solar cell with potential efficiency of 27.4%

Scientists in India have simulated a perovskite cell based on methylammonium tin iodide which they claim may achieve a short circuit current density of 25.97 mA per square centimeter, an open-circuit voltage of 1.203 V, and a fill factor of 87.79%. The cell is composed of a fluorine-doped tin oxide (FTO) substrate, a titanium oxide layer, a methylammonium tin iodide perovskite film, a copper oxide hole transport layer (HTL), and a layer made of gold (Au).

CEA-Ines achieves 19.2% efficiency for flexible perovskite solar cell

The cell was fabricated with a flexible substrate made of indium tin oxide (ITO) and polyethylene terephthalate (PET). The device was tested through a damp heat test and showed it can retain around 90% of its initial efficiency after 800 hours.

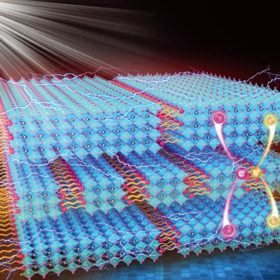

Sandwich structure of quasi-2D perovskite film nourishes next-gen solar development

Even as solar researchers strive to squeeze every drop of efficiency from the industry-ruling silicon solar-cell technology, scientists are constantly questing for the next, cheaper, more efficient way of harvesting the sun’s energy to power human endeavours. The appetite for accelerating 2D perovskite solar cell development has just been piqued!

US scientists gain an atom-level view into perovskite cell efficiency

Using Department of Energy laboratories, scientists learned at the atomic level that a liquid-like motion in perovskites may explain how they efficiently produce electric currents.