Solar manufacturer Yingli and communications brand Huawei will work together on the deployment of ‘smart energy and power,' the two companies announced at the SNEC industry conference and exhibition.

High-level officials from both companies were in attendance in Shanghai on Thursday to announce the partners will work closely to establish a national photovoltaic-technology personnel training center; and a smart energy production facility; factory and big data facility, to help develop the Chinese PV market.

BYD Solar debuted several modules at the event, including a half-cut, 210mm-wafer based product; a 182mm module; a 182mm bifacial, duo-glass device; and TOPCon (tunnel-oxide passivated contact) and heterojunction panels.

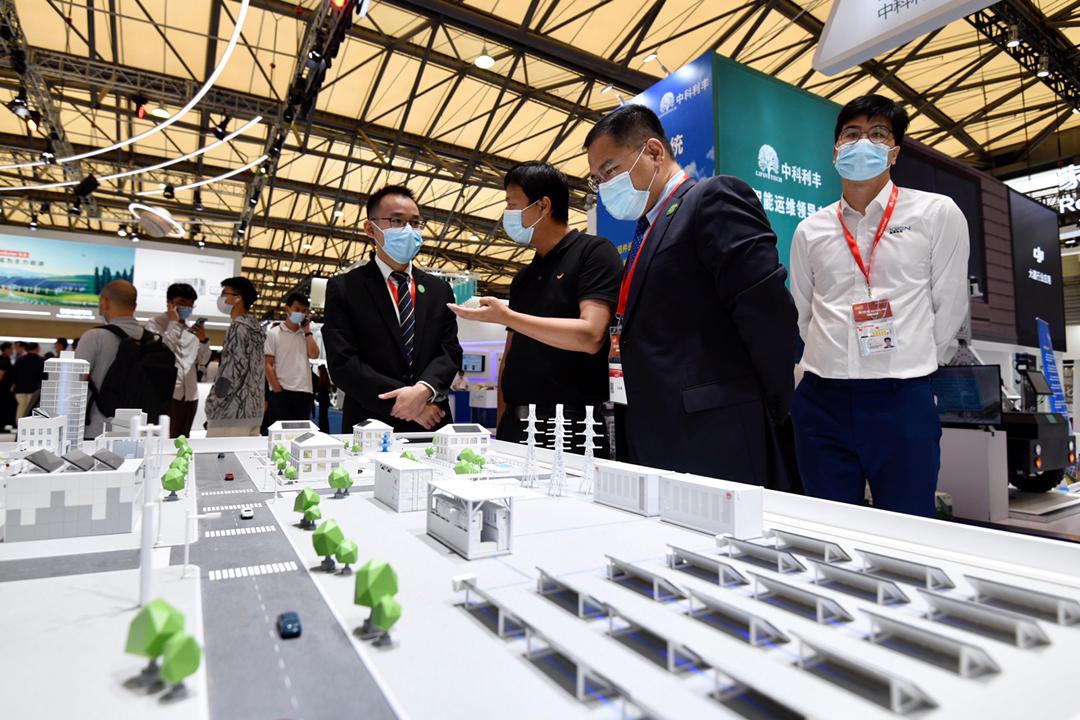

Image: Dave Tacon for pv magazine

With BYD better known for electric vehicle production, general manager Bi Guozhong said the business is focusing on the rapidly growing solar market and is playing catch-up with more established PV manufacturers with the intent of making up the ground within one to two years.

Bi said BYD's heterojunction panels promise great potential as they offer the chance to harness perovskite technology and potentially lift module efficiency to new highs.

Inverter maker Sineng used Thursday's opening day of SNEC to announce its 1500 V, large-current inverter – with a maximum power of 352 kW and rated power of 320 kW – has been listed in its product portfolio as ready for market.

Compatible with solar modules based on 182mm and 210mm wafers, Sineng says the device offers 20 A and has an MPPT (maximum power point tracking) range of 500-1500 V, with a maximum input current of up to 45 A. The manufacturer said the maximum power efficiency of its 320K-H series string inverter is up to 99.93%.

LDK used SNEC to release its S series solar modules with He Liang, VP of the company's R&D center explaining the products are based on rotating casting mono-poly silicon technology, and take advantage of higher yield and lower energy costs in their production process.

The manufacturer claims an average conversion efficiency of more than 24% across its products and says its panels are produced for around 16% less than their conventional rivals.

Tracker maker Arctech Solar launched what it described as the first wireless synchronous adjustable bracket at the conference and exhibition and announced 100 MW worth of orders from state-owned solar demonstration projects.

pv magazine print edition

The bracket eschews the usual push-rod design for a simple screw-rod assembly which Arctech says is tolerant to harsh environmental conditions. The manufacturer said the innovation uses an independent push-rod instead of the standard push-rod assembly as its main driving force, ensuring a stable retention force at the same time as the driving force.

After removing the connecting rod, Arctech said at the SNEC exhibition which closed on Saturday, the regulating device adopts wireless signal transmission instead of the usual connecting-rod synchronous structure, and develops a new motor driver which can not only realize stepless angle adjustment from five to 60 degrees in a minute, but also ensures the consistent operation of multiple motors to enable the synchronous angle adjustment of all brackets.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.