Effects of Swirl defects in solar cells based on Czochralski wafers

Scientists in China analyzed defective solar cells based on Czochralski (Cz) silicon wafers and found Swirl defects may be responsible for an efficiency drop of up to 4.7%. According to them, the presence of Swirl defects could be mitigated by applying a heat treatment at a temperature above 1,050 degrees Celsius in a clean environment before the manufacturing of the solar cells.

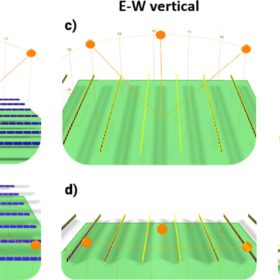

Optimal topology for agrivoltaics based on bifacial PV modules

A research team has outlined an optimized array topology for agrivoltaic projects built with bifacial modules. According to its findings, the benefits of bifacial PV arrays are most prominent in stilt mounted projects, where modules are elevated considerably off the ground at over 2 m, thus allowing plenty of light to be absorbed by the rear PV side as well.

Chinese PV Industry Brief: China added 53 GW of new PV capacity in 2021

The National Energy Administration (NEA) reported this week that the newly installed PV capacity for the Chinese market reached around 53 GW last year. Of this capacity, around 29 GW comes from distributed generation projects. The country’s cumulative installed power reached 306 GW at the end of December.

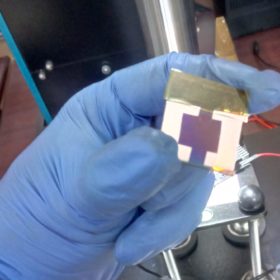

Four-terminal perovskite/silicon tandem solar cell with 15.5% efficiency

Researchers in India have built the 4T device with top and bottom cells based on large-area semi-transparent perovskite cells with copper metal contacts. Copper has been used instead of expensive gold with the aim of reducing the cell’s overall cost.

India’s REIL opens bids to supply 200,000 silicon PV cells

Rajasthan Electronics and Instruments is accepting bids from Indian manufacturers to supply five-busbar monocrystalline and multicrystalline silicon solar cells rated for a minimum of 4.62 W. Bidding closes on Jan. 27.

TOPCon vs PERC

TOPCon solar cells are on their way to fully compete with PERC solar products, according to recent research from Germany’s Fraunhofer ISE. Efficiency gains for the TOPCon concept, however, are necessary to help it capture more market share, as production costs remain higher than those for PERC tech. A series of cost-driven strategies to make TOPCon modules advance were outlined in the study.

Full solar value chain relief is on the way, says ROTH Capital

Philip Shen, managing director of ROTH Capital Partners, hosted top analysts from PV InfoLink to discuss their outlook on pricing, supply and demand at each step in the solar value chain.

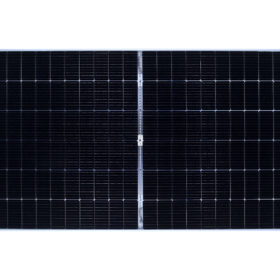

Vikram Solar launches M10 solar modules

The Indian manufacturer has unveiled its Series 10 monocrystalline PERC solar modules featuring 144 half-cells based on an M10 wafer. The modules are available in monofacial and bifacial versions with a maximum efficiency of 21.33% and 21.13%, respectively.

Chinese PV Industry Brief: Longi unexpectedly raises PV wafer prices

Furthermore, Tongwei secured 104,800,000 wafers from Shuangliang and PV module manufacturer Yingli said its capacity has reached 8GW.

Spraying water system for solar module cooling

A British-Indian research group has developed an active cooling technique that is claimed to improve a PV system’s yield by around 0.5%. The system could be used in residential solar arrays and the water heated by the PV modules may be fed into a solar water heating system.