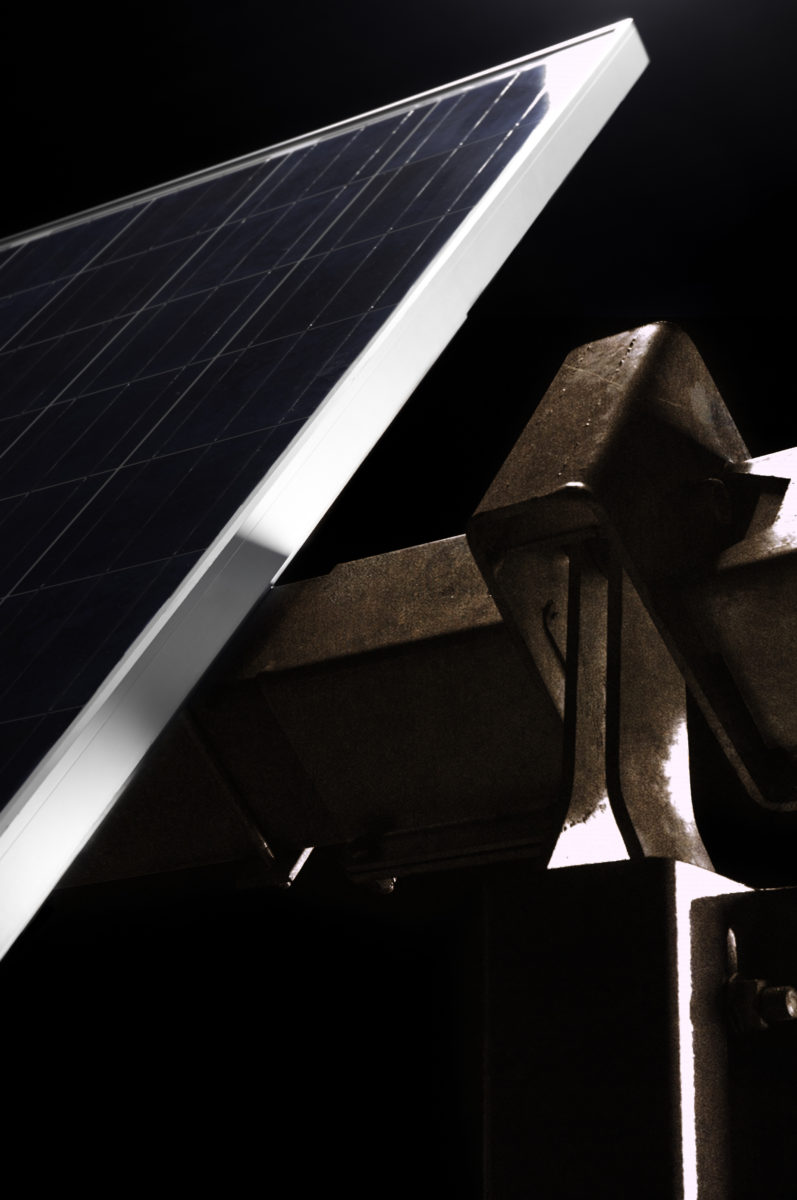

Convert's new product is a single axis tracker made in Weathering Steel. The innovation of TRJ-WS, in respect to the current TRJ tracker, stands in protection against corrosion, obtained by using Weathering Steel (WS) instead of Hot Dip Galvanized Steel or other protective treatments.

Currently, Trackers available on the market need a surface treatment, in order to protect them from environmental conditions. Most times, they are Hot Dip Galvanized.

TRJ-WS, thanks to the spontaneous process of passivation when exposed to atmospheric conditions, is the first tracker available on the market that does not need any treatment on the surface, and at the same time, offers high reliability and analogous structural properties and maintenance requirements needed by traditional coated based galvanic protection trackers.

Technological benefits deriving from the use of the TRJ-WS tracker can be summarized as follows:

Popular content

- Reduced production time and easier logistics, thanks to the elimination of HDG phase in the manufacturing process; considering that galvanizing facilities are often far from steel manufacturing sites.

- Enhanced assembly capabilities, thanks to the possibility of mechanical machining without the need of galvanizing treatments.

- Possibility of designing calculated service life in accordance with site requirements (also over 25 years) through correct dimensioning of the top layer.

- No risk of compromising corrosion protection coating during transportation and mounting phases.

Other benefits for the environment and society associated to the use of TRJ-WS are:

- Lower energy requirements and CO2 emissions in the production phase. These aspects have been analyzed considering the energy saved through the elimination of galvanization process and the CO2 required for the production of both steel and zinc.

- High recyclability, since the absence of zinc residual, allows achieving a cleaned recycled product.

- Lesser release of oxides during the service life, since they remain bonded to the steel surface, forming the patina. Furthermore, the remainder oxides released in environment are not toxic.

“The TRJ-WS is the result of the Research and Development Department of Convert, finalized to reduce LCOE,” states Antonio Timidei, Research & Development manager at Convert. The project was born from the analysis of the use of a steel generally used for big infrastructures such as bridges, and adoption for light structures such as the Tracker.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.