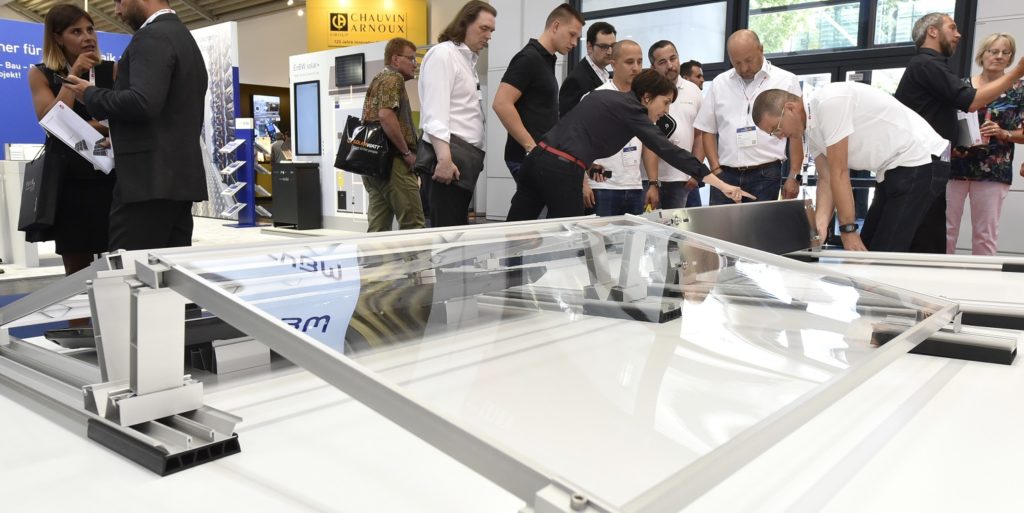

Recently, Marco Stifel, product manager at K2 Systems presented the company’s most recent developments for PV systems on flat roofs. Among other benefits, ballast can be reduced by between 20-30%, said Stifel, while a new support mat can compensate for movements caused by thermal expansion of the substructure and modules.

In addition to Marco Stifel, Günther Fischer, Professor at the University of Applied Sciences Esslingen, Department of Mechanical Engineering Plastics Technology, explained the interactions between roofing membranes and applied plastics; and why, in his opinion, the new pad is harmless.

Following on from the webinar, K2 Systems answers the questions that could be posed, due to time constraints.

What is the weight per sqm on the roof?

The weight of the new Dome V System itself on the roof is 2.1 kg/m², without any additional ballast and also excluding PV modules.

How much force is needed to press one of the EPDM pads flat on the roof?

The new Mat V will never be completely pressed on the flat roof because of its detailed and innovative design, which enables that, according to the load situation, the EPDM pad cannot be pressed flat; we call it safety position.

How much is the friction co-efficiency?

The friction coefficient must be measured individually on each roof, because it depends on several factors. This value is project-specific, but you are welcome to watch our video to determine the friction coefficient. In addition, we have a ready-to-use protocol, in which you can enter all relevant data. And in our article, you can read more about the friction coefficient.

What is the percentage reduction in roof loading, compared to a standard ballasted mounting system?

The percentage reduction of the roof load compared to a standard ballast is approx. 15 – 30 percent.

What is lowest kg/m2 load we can reach with the new mounting system?

The lowest load (kg/m²) for the new Dome V mounting system is 2.1 kg/m², without the module. That means, that apart from corner and edge zones on the road and according to the load situation.

Is the system also suitable for sealed ground mounted surfaces?

Yes, definitely. We are flexible in the connection to the ground. With screw anchors we can, for example, screw directly into concrete foundations.

How long are the warranties?

We grant 12 years warranty on our products.

Popular content

How do you determine the maximum permitted load for the roof membrane itself, i.e. not the insulation layer?

You can obtain information on the permissible load of the membrane from the data sheet of the membrane manufacturer. We will show you exactly which loads the mounting system can carry, and these loads have to be compared with the data of the roofing membrane manufacturers.

How did wind resistance improve with the new system?

The wind resistance has not changed, because it is based on the same parameters of the wind tunnel test.

What is the percentage error in the software's wind loading calculations and how do you compensate for it?

We dimension with international building regulations, such as ASCE, or Eurocode. These standards work with the semi-global security concept. Loads like wind conditions are compared with the load capacities of the structure. Global safety factors consider statistical uncertainties.

How does the EPDM tolerate freezing temperatures and snow?

Up to a limit of -30°C there will be no problems with frost and snow.

What is the expected lifetime of EPDM?

Under normal conditions, there is no limit to the lifetime of EPDM.

Have you tested the system for salty environments? What are your findings?

The salt has no influence on the used materials, like aluminum T66 and EPDM. Therefore, a test is not relevant.

In a Saudi Arabian Scenario, there would be heavy sand loads. How do you manage this?

Heavy sand loads are no problem for the new Dome V system. Concerning the pressure, heavy sand loads are comparable to the snow loads. We covered these and have already implemented many successful flat roof projects in the desert region

Listen to the webinar and download the presentations

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.