While many analysts believe hydrogen has a vital role to play in the clean energy transition – and commercial applications are already taking shape – the electrolyzers required to produce it from renewable power remain expensive to operate, thanks in part to a need for precious metals to catalyze the chemical reactions that split water into hydrogen and oxygen.

With researchers on the hunt for cheaper alternatives, promise has been shown by spinel oxides – materials with a particular crystalline structure. However, understanding about how they work as an electrolysis catalyst is limited.

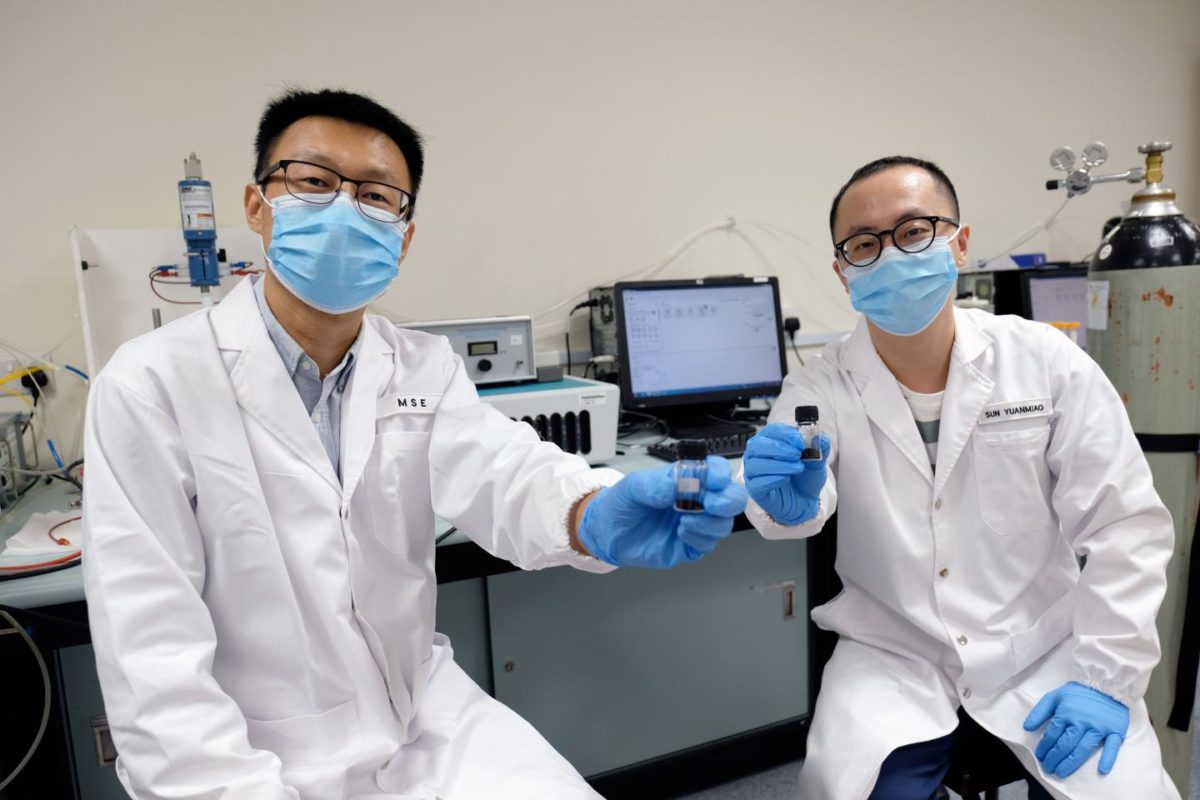

Scientists led by staff from Singapore’s Nanyang Technological University (NTU) sought to observe spinel oxide catalyst workings at the atomic scale in a bid to simplify the identification of potential new catalysts and open up possibilities for further improvements in water electrolysis. “By identifying the parameters that make spinel oxides good catalysts for this process,” said NTU associate professor Jason Xu Zhichuan, “we can create new, better spinel oxides based on these parameters, bringing us one step closer to a hydrogen-powered economy.”

Oxygen evolution

Hydrogen production via electrolysis is driven by two main chemical reactions, one produces hydrogen and the other, oxygen, which is separated from hydrogen in the electrolyzer by a membrane. It is the oxygen-producing reaction which requires catalysts to improve efficiency. “The oxygen evolution reaction is critical to the efficiency of devices that split water to produce hydrogen fuel, but it is also a sluggish chemical reaction that lowers the overall energy conversion efficiency,” said Xu. “This is why we need catalysts such as metal oxides to speed things up.”

NTU’s findings can be found in the paper Covalency competition dominates the water oxidation structure-activity relationship on spinel oxides, published in Nature Catalysis. The group found, the catalysis is caused by competition for chemical bonds between different areas of the material and the exposure of more reaction sites.

Armed with that knowledge, the researchers were able to develop a machine learning model to predict the effectiveness of spinel oxide catalysts. The model highlighted one – based on manganese and aluminum – from a list of more than 300 materials and the group confirmed its superior performance in experiments.

NTU said the paper sets mechanical principles for spinel oxides which could extend over a range of applications. While the results are encouraging for hydrogen production, though, Xu noted bottlenecks remain.

“We have to improve the membrane in such alkaline electrolyzers to support long-term hydrogen production,” he said. “When that’s done, then we can work with our engineering colleagues to see how we can put all of these upgrades into an electrolyzer that can function on an industrial level.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.