Battolyser Systems has developed an energy system to store and supply electricity as a battery and produce hydrogen via electrolysis. It is an optimization of the nickel-iron battery patented by Thomas Edison at the turn of the 20th century.

The company, which recently started production of its patented dual battery-electrolysis system in the Rotterdam area, currently produces systems up to a couple of megawatts. It aims to manufacture 50 MW systems in its production facility by 2024, and 200 MW by 2025.

“The technology is based on nickel-iron electrodes. They are combined with alkaline electrolysis technologies that are commercially available today, with a proven track record of 20 to 30 years lifetime,” said Geert Wassens, fundraising associate at Battolyser Systems. “Integration of these technologies remarkably improves performance, lowers cost and increases uptime.”

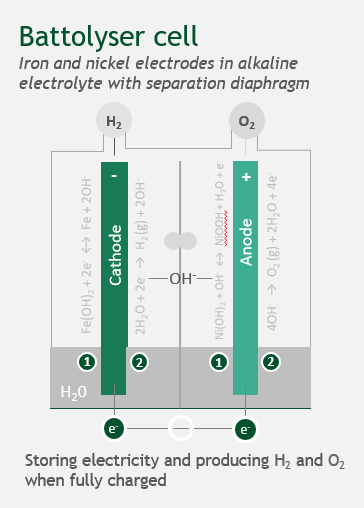

The electrodes are in a conductive electrolyte circulated through the cells. In the first electrochemical reaction, the electrodes are charged and store electrons, acting as a battery. When one keeps charging (overcharge), hydrogen and oxygen are formed in a subsequent reaction. Gaseous hydrogen is produced at the negative electrode (cathode) and oxygen at the positive electrode (anode).

and store electrons, acting as a battery. When one keeps charging (overcharge), hydrogen and oxygen are formed in a subsequent reaction. Gaseous hydrogen is produced at the negative electrode (cathode) and oxygen at the positive electrode (anode).

The company said the system could hit a lower LCOH of around €1.50/kg in the most appropriate locations by 2025.

“In the most favorable geographies, the Battolyser is able to offer ~€2/kg by 2025. An important note to this analysis is that it does not yet include the positive economic impacts of discharging electricity from the Battolyser to the grid, it only considers revenue from producing hydrogen,” Wassens told pv magazine. “Therefore, the advantage in LCOH of Battolyser over competing alternatives will be even greater. Including this value, the LCOH is near to €1.50/kg.”

Battolyser Systems said the battery function can monetize daily power imbalances, while the hydrogen can monetize seasonal power imbalances and provide feedstock to industries that cannot be electrified. It said it can reach up to 85% system efficiency and up to 90% at stack level.

Battolyser Systems has signed a deal to develop a second production facility in the Rotterdam area. In 2026, the production facility, co-owned by the Rotterdam port authority, will be commissioned to add 1 GW of production capacity.

Popular content

Battolyser Systems and the European Investment Bank (EIB) have also signed a €40 million financing agreement in Rotterdam during World Hydrogen Week.

“The financing will enable the company to scale its production facility in Rotterdam towards mass production of its combined electricity storage and electrolyzer stack system,” said Battolyser Systems.

The company will allocate a portion of the funds to establish the new production facility. It is also gearing up for another investment round, scheduled to launch within 18 months.

“We are targeting customers in Europa and have commercial conversations with projects in MEA and the US,” said Wassens.

The first two factories will be in the Rotterdam area, but the company see the United States as “the next step,” he added.

The company said it does not use any critical raw materials, resorting only to nickel and iron, in line with the recent normative and political developments at the European level, including the RED II and the Critical Raw Materials Act.

“We have a number of hydrogen projects in the pipeline that we are looking to sign in the near future, although perhaps not necessarily still this year,” an EIB spokesperson told pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.