From pv magazine 10/2020

Frames, junction boxes and copper cabling are removed, manually or automatically, and the module is broken up in a shredding machine. The remaining materials are sorted mechanically: Glass, aluminum, and ferrous metals can be extracted this way, with the balance of silicon, metals, plastics and glass that cannot be separated making its way to landfill. “This simple recycling method avoids most masses to be landfilled with relatively low energy input and processing costs,” state scientists from the University of New South Wales (UNSW) in a recent paper examining the state of the art in PV module recycling.

European solar recycling association PV Cycle estimates that the world’s only dedicated PV module recycling plant, operated by Veolia in the south of France, can do slightly better, recovering on average 94.7% of the total weight of a module. But while these materials are at least temporarily prevented from ending up in landfill, the lack of cost-effective extraction processes for most materials, and of an overall PV recycling ecosystem, means there’s little chance much of the material will end up as part of another solar module. The metals are returned to their respective industries. Glass can typically end up as fiberglass, insulation material, or a substitute for construction sand. The lower purity silicon recovered, meanwhile, has low value and will likely end up processed into a silicone plastic. And it should also be noted that while the solar industry is making progress on recycling ahead of the massive volumes on the horizon, the majority of modules worldwide reaching end of life today will be destined for landfill sites.

Can solar do better when it comes to recycling? The answer from the academic community is a resounding yes. In the past three years alone hundreds of research papers have been published on this topic, with processes demonstrably able to purify silicon from cells to the point where it can be fed back into ingot production, and to extract and reuse the minuscule amounts of silver, lead and other metals from a module. Implementing these at scale as part of a circular economy for solar products, however, is still going to require a whole lot of combined effort from the technology, policy and financial spheres. “The volume of PV recycling is very low at the moment, and the quality of recycled material is not good enough to go back into PV production,” says UNSW researcher Rong Deng. “Most high value recycling approaches remain in the research or pilot phase, with little experience in industrial settings.”

Separation anxiety

PV modules are not designed to be taken apart. This has clear environmental benefits in terms of longer operational lifetimes, and second life applications will likely have their part to play in the developing landscape for PV end-of-life treatments. For recyclers though, taking apart the main module stack of glass/encapsulant/cells/encapsulant/backsheet or rear glass is a major headache.

Mechanical shredding/cutting processes are good for separating larger fragments of glass from the mix, and can be scaled up relatively easily. But separating silicon, plastics and other materials in this way is more difficult. The encapsulant material with which modules are laminated, most commonly ethylene vinyl acetate (EVA), causes the problem here, and none of the available options to deal with it is especially attractive.

In thermal delamination, EVA can be converted into various gases via pyrolysis in an inert environment, or simply burned off under oxygen, allowing recovery of the intact silicon cells. Such processes would likely be energy intensive, and for the majority of modules that utilize fluoropolymer backsheets this would necessitate another separation step, as the backsheet can only be treated thermally if additional measures are taken to prevent the hydrofluoric acid this would produce making its way into the environment. Chemical delamination, meanwhile, would likely leave large amounts of a toxic solvent to dispose of, creating a bigger environmental issue than the one it solves.

Next step

After the bulk of the frame and the glass, it is the silicon in the wafers that makes up the next biggest chunk of the module. The wafer is also the most expensive component in a module, and solar grade silicon demands a significantly higher price than the metallurgical grade that is currently recovered – providing an economic incentive for future research. For now though, PV Cycle estimates a treatment cost of around $50/kg to purify silicon to the point where it could be reinserted into the PV supply chain, a far cry from recent spot prices for monocrystalline grade polysilicon that sit just above $10/kg. Larger volumes alone might help to bring this cost down in future, but it’s fair to say that recycling silicon will remain economically challenging for a while yet.

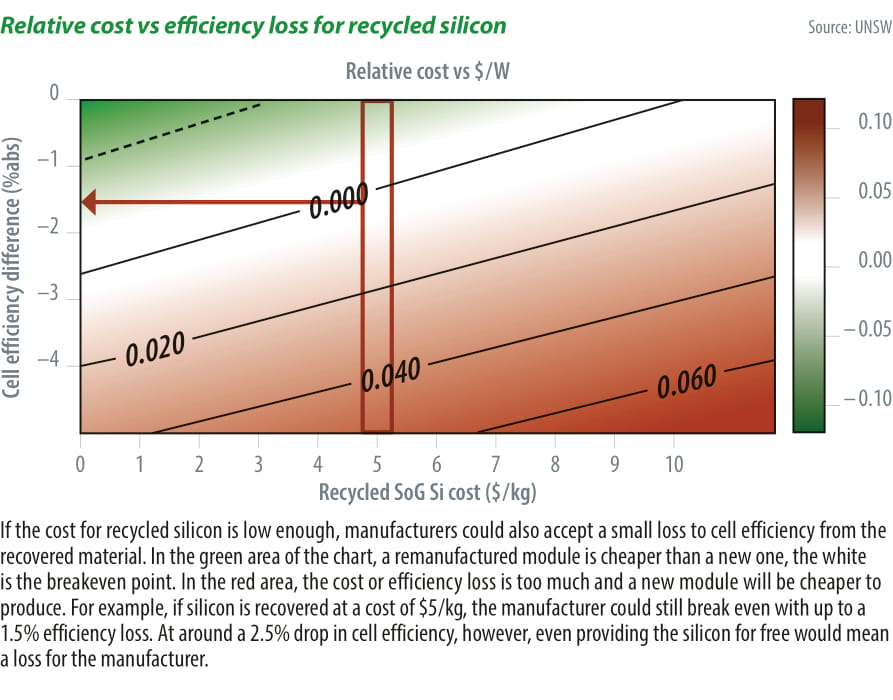

An example from UNSW’s recent work, presented at the EU PVSEC conference last month, finds that, based on recent polysilicon prices, breakeven would require a retrieval cost of around $5/kg for recycled solar grade silicon. This price would allow for a 1.5% drop in efficiency in the remanufactured module (see chart below). If there is no efficiency loss, the recycled module could actually be around 8% cheaper. The cutoff point for efficiency loss from recycled polysilicon is 2.5% (absolute efficiency), at this point even providing the silicon for free would result in additional costs for the module manufacturer.

Recovery of intact wafers which can then be reinserted into cell manufacturing is economically easier. UNSW’s work estimates that an overall cost of $0.38 per wafer could be acceptable to manufacturers, allowing for a 0.2% efficiency loss in the end product. But thanks to the likelihood of cracks and other damage in the second life wafers, changes to the size and thickness rendering older wafers obsolete, and further falling prices, this is unlikely to get off the ground. “Our recent study showed that using recycled wafers can save up to 24% of module cost, and reduce the environmental impact by 50%,” says Deng. “There may be a small market for intact recovered wafer due to this low cost, but we don’t expect it to become mainstream recycling practice anytime soon.”

Purification processes

So with the potential to both increase the economic attractiveness of recycling PV modules, and to reduce the environmental impacts of their manufacture, viable processes to recover solar grade silicon are emerging as a priority. This was also the conclusion reached in another study led by Garvin Heath of the U.S. National Renewable Energy Laboratory (NREL), which lays out a series of recommendations for PV recycling, the first of which is to “emphasize R&D on high value silicon recovery.”

For recycled silicon to find a market among ingot producers, a better understanding of its characteristics, as well as optimized processes for its purification will first be needed. Heath et al. note that solar grade polysilicon is currently at least 99.9999% (6N) pure, with manufacturers regularly adding more nines to their requirement. And for an industry that has met the challenge of extremely high purity with virgin material, adapting to process recycled silicon to the same level should be an achievable goal. “We see no physical reason why the high-grade silicon embodied in solar cells cannot be reformed into solar-grade silicon,” the NREL paper states. “The challenge and research opportunity are in re-optimizing existing processes or developing new processes for the impurity profile and physical form of recovered silicon, all at reasonable cost.”

And work on this has already begun. German company Luxchemtech has demonstrated a process where modules are treated and refined to a powder of the cell materials, which is then purified through a chemical etching and rinsing process. And with input from the Korea Institute of Energy Research and ingot pulling equipment supplier S-Tech, samples of silicon recovered in this way were found to have better than 5N purity, and were further processed into ingots where the recycled material made up 15%. Overall purity of these ingots was measured at better than 7N. The ingots were further processed into wafers, and then BSF cells that achieved better than 18% efficiency.

Luxchemtech’s purification process can also extract silver from the modules, potentially improving the economics of the recycling process and easing pressure on the silver supply chain. While no information is available on the cost of the process, CEO Wolfram Palitzsch is confident that recycled silicon can be sold for less than new, and states that the economics of PV recycling should be seen from an ‘all materials’ perspective. “In order to set up recycling that is as economical as possible, all components must be considered. Giving up the silver, you will end up with an overall process that’s too expensive,” he explains. “In the end, it will be a mixed calculation.”

Chicken, egg

For now, PV recycling technology, and the wider establishment of a circular economy for the industry, remains in something of a ‘chicken-egg’ situation. Low volumes of waste limit the development of processes as well as business models, and the lack of developed processes limits the volume of waste that can be recycled. “Based on this situation, and the many different approaches being trialed, we cannot conclude which technology is the best option to scale-up to industrial levels,” says Deng. “There are uncertainties in the recycling yield, recycled material quality, and infrastructure costs, which will affect the economic revenue of recycling practices.”

And for recyclers to develop technologies that can really keep module materials circulating indefinitely and even save money in the long-run, support will be needed from other stakeholders. As a first step, UNSW recommends that governments step in to set new recycling targets, increase landfill costs to incentivize recycling, implement effective collection and transportation systems for EOL modules, and continue to fund pilot-scale recycling projects.

Manufacturers, meanwhile, should work to consider how they can incorporate recycled materials into their supply chains. Requirements for the material’s purity and other characteristics will need to be clearly communicated. And at the same time, working ecodesign principles into products and striking the right balance between quality and longevity and the ease with which materials can be recovered will be vital in bringing solar’s environmental impacts to a minimum through recycling and the establishment of a circular economy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.