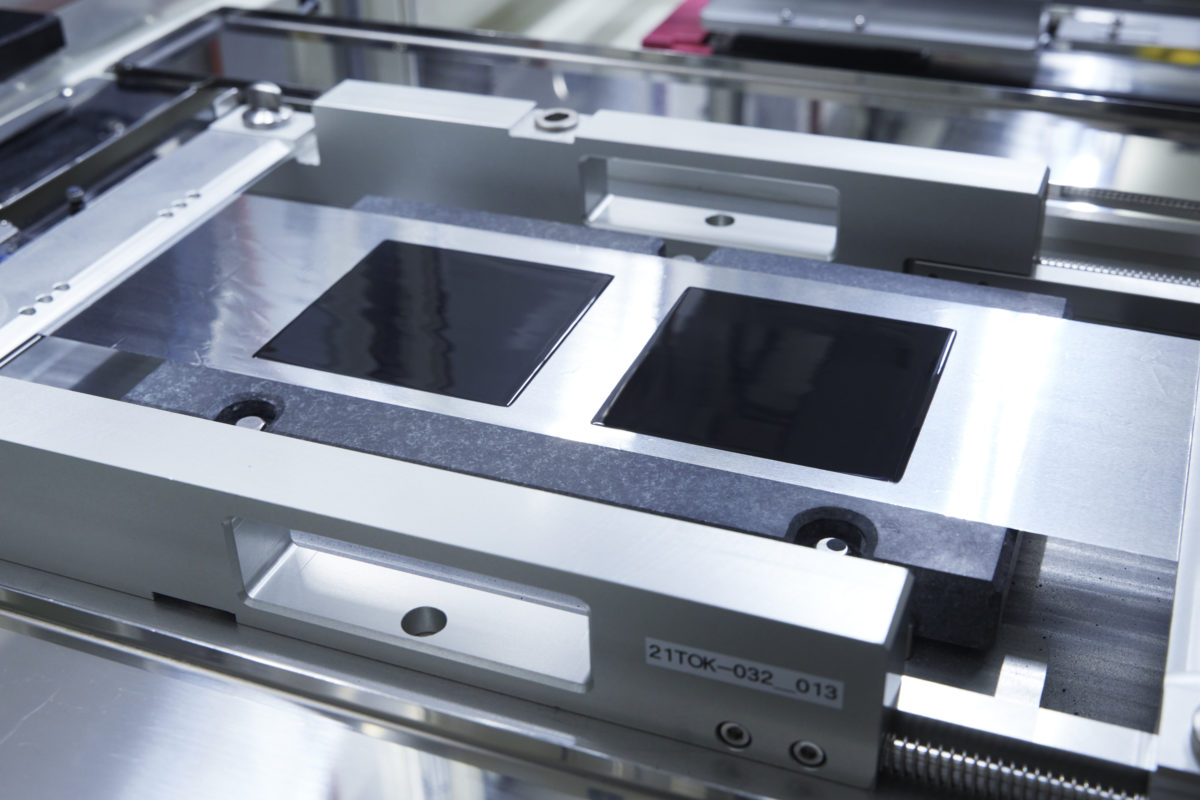

Often touted as a potential game-changing technology for accelerating the adoption of electric vehicles (EVs), all-solid-state batteries boast an energy density approximately twice that of conventional lithium-ion batteries, significantly shorter charging times, and lower cost thanks to less expensive raw materials. While many Western legacy carmakers continue to invest heavily and forge partnerships with solid-state battery specialists, like QuantumScape or Prologium, to develop vehicles powered by this type of technology, Nissan has made key progress towards producing its own version of solid-state batteries for EVs. To keep all production in-house, the Japanese carmaker has unveiled its prototype manufacturing facility for laminated all-solid-state battery cells at its research center in Kanagawa Prefecture. Under its Ambition 2030 vision, Nissan aims to launch an EV with all-solid-state batteries developed in-house by fiscal 2028. Its plan is to establish a pilot production line at its Yokohama Plant in fiscal 2024 to study materials, design, and manufacturing processes for prototype production. The maker of the world’s first mass-market EV, the Leaf, believes the cost of all-solid-state batteries can be reduced to US$75 per kWh in fiscal 2028 and to $65 per kWh thereafter, placing EVs at the same cost level as gasoline-powered vehicles.

When it comes to affordability of EVs, Japanese carmaker Honda and U.S. corporation General Motors have come together to “put people all over the world into EVs faster than either company could achieve on its own.” The two car manufacturers will codevelop a series of affordable EVs based on a new architecture using GM’s Ultium battery technology. The tie-up is expected to produce millions of EVs priced below $30,000, including popular compact crossover vehicles, beginning in 2027. GM is already working to accelerate new technologies like lithium-metal, silicon, and solid-state batteries, along with production methods that can be used to improve and update battery cell manufacturing processes. Meanwhile, Honda has established a demonstration line in Japan for all-solid-state batteries, which it sees as the core element of future EVs, and is making further progress toward mass-production. The two carmakers will also discuss future EV battery technology collaboration opportunities, to further drive down the cost of electrification, improve performance, and drive sustainability for future vehicles. “GM and Honda will share our best technology, design and manufacturing strategies to deliver affordable and desirable EVs on a global scale, including our key markets in North America, South America and China,” said Mary Barra, GM CEO. “This is a key step to deliver on our commitment to achieve carbon neutrality in our global products and operations by 2040 and eliminate tailpipe emissions from light-duty vehicles in the U.S. by 2035.”

Earlier this week, Barra herself, alongside Tesla’s Elon Musk and other automotive industry representatives, met with Biden administration senior officials to discuss EVs and charging infrastructure. The virtual meeting held on Wednesday yielded an agreement that the US EV charging network should offer an interoperable experience based on any car model. CEOs of Ford, Stellantis, Nissan Americas, Lucid and others also attended the meeting which discussed the US funding to “create a national network of 500,000 chargers.” Biden wants at least 50% of new vehicles by 2030 to be EVs or plug-in hybrids. In February, the administration rolled out a plan to award nearly $5 billion over five years to build thousands of EV charging stations every 50 miles (80km) along interstate highways, as part of a $7.5 billion funding package approved by Congress last year.

Popular content

In Europe, EV batteries made by Mercedes-Benz will be given a new life in stationary energy storage systems. Swedish startup BatteryLoop said it will use batteries supplied by the German carmaker’s Mercedes-Benz Energy business line for its range of scalable, circular energy storage solutions, called BLESS. This could enable BatteryLoop to roll out 40MWh of energy storage systems within the next 18 months. The first project using Mercedes-Benz Energy’s modules will be a 2MWh system that the start-up, part of Swedish recycling company Stena Metall Group, will install in its home country. BatteryLoop said it will secure “high volumes” of batteries, both new and second life, through the deal. “With second-use batteries and a power-optimizing system we can also, based on the Swedish environmental research institute lifecycle analysis, save 1,000-tonnes CO2 emissions per 3MW energy storage system from the production and at the same time generate the same benefits for the grid,” BatteryLoop CEO Rasmus Bergström said, adding that such systems can generate significant revenues for customers of between SEK7 million (US$0.75 million) to SEK10 million per year.

This week, Mercedes-Benz revealed that its EV sales are going through the roof. The carmaker said the sales of its EVs and plug-in hybrids has increased by 37% to 67,800 units in the first quarter of 2022. Sales of the fully electric EQ models more than tripled to 21,900 (up by 210% compared to Q1 2021). “Ongoing strong demand for our electrified vehicles in all segments and markets proves that customers desire our EVs und plug-in hybrids. And with the launch of our new EQS SUV on April 19th we further accelerate our transformation,” said Britta Seeger, Member of the Board of Management of Mercedes-Benz Group AG responsible for Mercedes-Benz Cars Sales. Thereby, the Stuttgart-headquartered luxury carmaker seems to have outperformed its Munich-based rival BMW, which saw an increase of 149.2% in global sales of its all-electric BMW and Mini vehicles. However, BMW delivered a greater number of all-electric vehicles – a total of 35,289 between January and March.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

9 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.