Until next year!

The doors have closed, the cleaners are in, and the pv magazine team is slowly making its way back home! If you were too busy to hear about all the latest news at this year’s Intersolar Europe, make sure you check out our live blog, which ran across the past three days. Here, we covered all the latest trends, product announcements, and hot gossip from the European solar and energy storage industries.

Overall, more than 65,000 visitors and 1,356 exhibitors from 149 countries attended the event, which was spread across 132,000 m2 and 12 exhibition halls.

Despite the supply chain challenges, high energy prices, and rising inflation, the mood was overwhelmingly positive, even when the rain descended, with industry veterans comparing the vibe to that of golden years past.

So, on a final note, here’s to Intersolar Europe 2023 and another strong year for the renewables industry.

The pv magazine team wishes everyone a safe journey home and a restful sleep tonight!

Sustainability report coming soon from Longi

With efforts to enhance the solar industry’s environmental credentials now accelerating, major PV module makers are increasing their transparency in terms of internal sustainability. Trina Solar is expected to release its first sustainability report in the coming weeks, and pv magazine learned today that the release of Longi’s report into the same subject is also imminent.

Gulnara Abdullina, vice president Europe for Longi Solar, met with pv magazine today and noted the company’s engagement in developing green hydrogen, its membership in the RE100 Initiative, and the forthcoming publication of its sustainability report as evidence of its commitment to environmental values across its supply chain.

Abdullina said that while there are supply chain challenges across the industry, spirits are still high at Intersolar. She noted that the company remains committed to supplying its partners in a timely fashion and to transparency in terms of sustainability.

Longi, a partner of pv magazine‘s UP Initiative, plans to soon reveal more details about its sustainability endeavors.

No project management required

According to myenergi Managing Director Carsten Pattberg, the installer’s favorite exhibit is in Hall B6. Anyone passing by there can visit the Zappi charging station, which can charge e-cars with 100% renewable electricity, without requiring a complex connection to the inverter. What is needed instead is a clamp that can be easily placed around the power cable at the grid connection point. It transmits information to the Zappi energy management system in the wallbox when excess electricity is flowing into the grid – no cable connection required.

The installation is made by companies acquainted with the product through online training. The training courses are very popular, said Pattberg. Around 70 installers have participated in the courses, which are held once or twice a week. The company's goal is to simplify the installation of wall boxes. “You don't make a project out of it when you buy a new television,” said Pattberg.

Formula E crash

Formula E – officially known as the ABB FIA Formula E World Championship – is coming back to Berlin this weekend. But the one-seater racing vehicle simulator exhibited at the Smarter-E show has had one crash it didn’t recover from: When we got to the furthest corner of Hall B6, the software was down and we couldn’t enjoy the experience.

Putting second-life PV modules to the test

Back on the PV waste trail this afternoon, pv magazine stopped by the 2nd Life Solar booth to find out about its innovative reuse concept. The Hamburg-based startup began life 15 months ago. It is part of the Buhck Group, a long-established waste management company that has 35 subsidiaries and 1,400 employees. Having dealt with end-of-life modules since 2016, they saw volumes increasing, and noted that not all modules needed to be shredded – there was a business case for reuse.

After a PV installation is decommissioned, 2nd Life Solar can test modules in a mobile lab and either qualify them for a second life, or send them to be recycled. They also have demonstration installations on their rooftop in Hamburg, and are exploring various routes to get the modules back into the market.

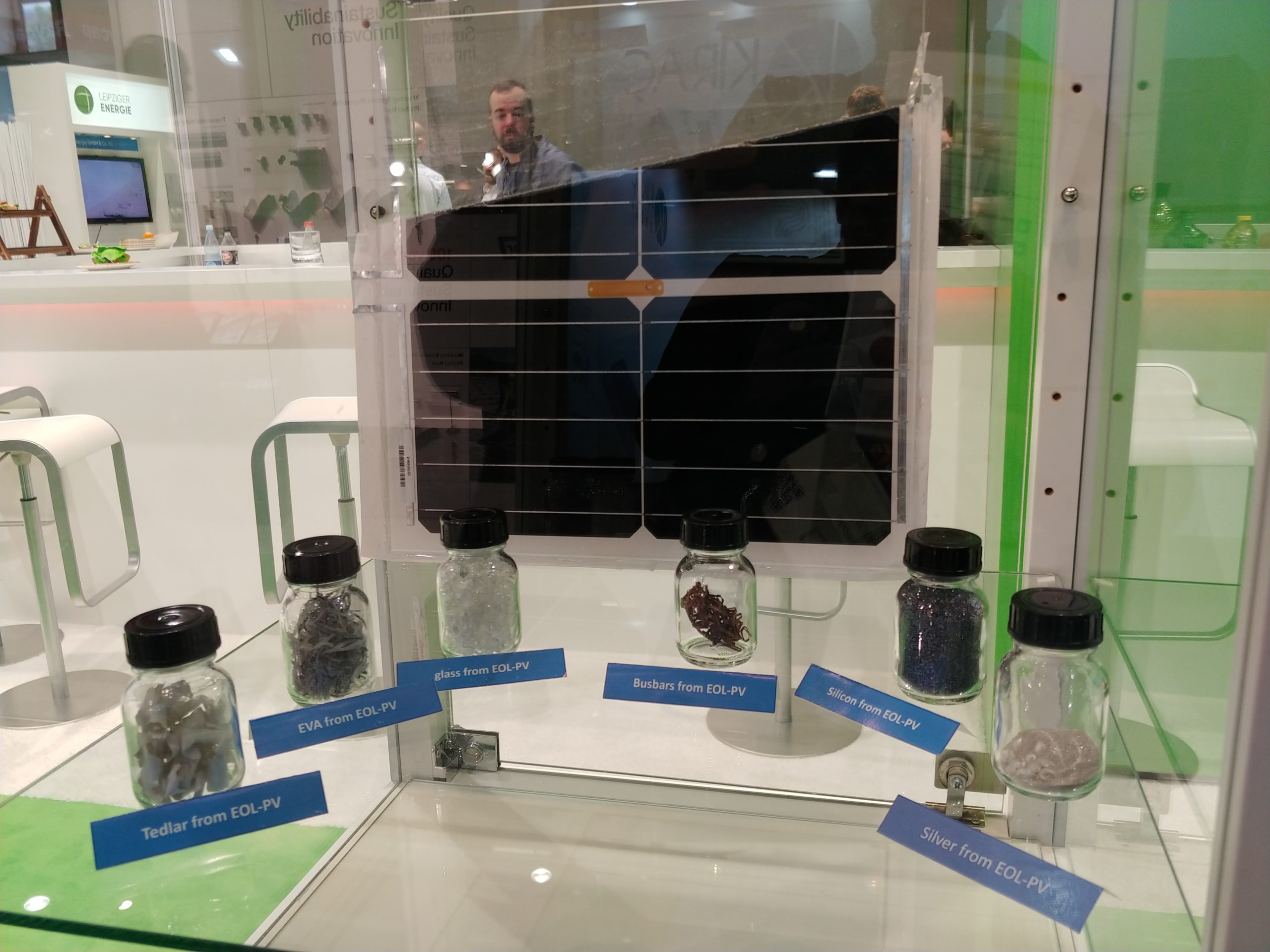

From PV modules to piles of powder

The enormous demand for PV that’s been on show this week also means, eventually, enormous volumes of PV waste that will need to be kept in circulation and out of landfill for the industry to make any claim to environmental credentials. And it’s encouraging to see this being taken seriously, with a few recyclers and reusers visible on the show floor.

Germany’s Luxchemtech has developed a process using a concentrated water jet to strip modules apart, and can completely separate the backsheet, encapsulant, silicon and busbars for introduction into various recycling streams.

CEO Wolfram Palitzsch told pv magazine that the company is seeking investors for a module recycling plant. What’s missing for now is the volume: For the facility to operate profitably it would need to process at least 10,000 tons of PV waste per year. And these must also be collected locally – within or close to Germany.

The 3 pillars of solar: Demand, finance, industry regulation

What are the three factors that determine the success of a solar manufacturing industry? “Demand, access to finance, and industry regulation,” said Rodrigo Lopes Sauaia, CEO of Brazilian solar PV association, ABSOLAR.

The first two pillars have been in place in Brazil for a while, but robust industry regulation had been lacking, Sauaia explained. With the elimination of several taxes on solar cells, modules, inverters, and trackers since August 2020, Brazil has the third pilar in place: industry regulation.

Sauaia is confident the country will be able to install 10 GW in 2022. Key industry players have already recognized the opportunity and have scaled up their presence in the country, Suaia said.

Brazil is seeing huge growth on a year-on-year basis, having 15 GW of installed capacity as of April 2022. It is set to become a top five solar market by 2026.

No project management needed

According to myenergi Managing Director Carsten Pattberg, the installer’s favorite charger is in Hall B6. Anyone passing by there can visit the Zappi charging station, which can charge e-cars with 100% renewable electricity without requiring a complex connection to the inverter. What is needed instead is a clamp that can be easily placed around the power cable at the grid connection point and transmits information to the Zappi energy management system in the wallbox when excess electricity is flowing into the grid. No cable connection required.

The installation is made by companies that have become acquainted with the product through online training. The courses are very popular, said Pattberg. Around 70 installers take part in the courses, which take place once or twice a week. The company's goal is to greatly simplify the installation of wall boxes. “You don't make a project out of it when you buy a new television,” said Pattberg.

A more enlightened market

Mitrex, a Canada-based BIPV building material manufacturer, is enjoying its first escapade into the European market at Intersolar 2022. CEO Danial Hadizadeh told pv magazine that he has noticed a much more knowledgeable solar market here in Europe compared to the United States, where he said the company has a significant pipeline. “The US still doesn't get solar,” said Hadizadeh.

The CEO added that he has been pleased by the interest that Mitrex has received from building developers who are looking for ways to incorporate solar into greenfield projects in the growing number of European municipalities that require solar, such as Berlin. Of course, high-rise developers have a particular interest in BIPV solutions due to limited rooftop space. “People building high-rises are being penalized,” Hadizadeh said, noting that the company's solutions enable it to meet solar requirements through integration.

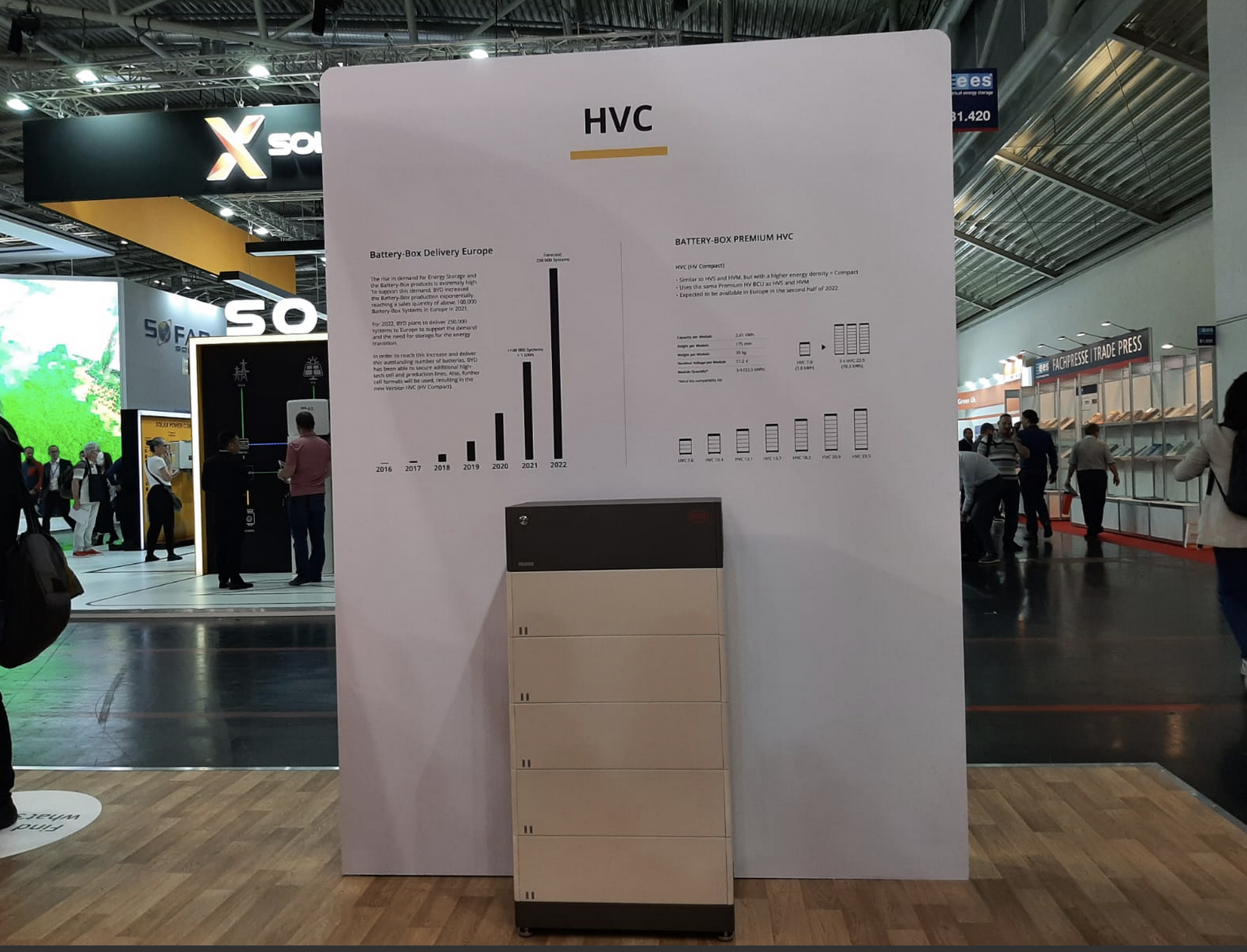

BYD looks to meet Europe’s surging battery demand

Chinese battery manufacturer BYD plans to deliver 250,000 of its flagship energy storage systems, BYD Battery-Box Premium, to Europe this year, in response to a high demand.

“Demand is through the roof,” Florian Blaser, operations director manager for Central Europe, told pv magazine.

BYD has expanded its production capacity for lithium cells to 250 GWh and has doubled the production lines for the Battery-Box modules. Presently, it has around 250,000 Battery-Box systems installed throughout the world, including 100,000 systems, or around 1 GWh, that were delivered to the European market in 2021.

This year, ambitious plans are in place to deliver 250,000 systems to Europe alone. According to Blaser, Germany remains the key market for BYD residential battery storage products, followed by other countries in the DACH region, as well as Italy and Spain. Demand is also growing significantly in the Benelux countries. Waiting times for products are said to be average, which in Germany presently means around five months.

The addition of new products to the company’s portfolio, including the Battery-Box HVC system – which was just introduced at the Smarter-E show and is will set for market launch in the fourth quarter – is expected to satisfy the market’s hunger for BYD battery products in Europe.

Try how easy it is

pv magazine‘s Julia Wolters reconsidered her career choice as she tested how easy it is to connect a solar array to an inverter at the Phoenix Contact booth. All you need is a well-considered connector system and a small screwdriver. Phoenix Contact has simplified the connections so that no special tools are required after stripping the cables. You only need to use a screwdriver if you want to remove the connector without destroying it, in order to use it elsewhere.

The economical use of plugs is currently very important because Phoenix Contact, like many companies in the industry, is having difficulties in meeting demand. The certified feed-in management system, in particular, is severely affected by the shortage of chips, explains Marc Mende, a spokesman for Phoenix Contact. The company has production facilities in Germany, Ukraine and Shanghai, so it is currently being hit hard by the turbulence on the world market. However, it promises to improve availability, product by product.

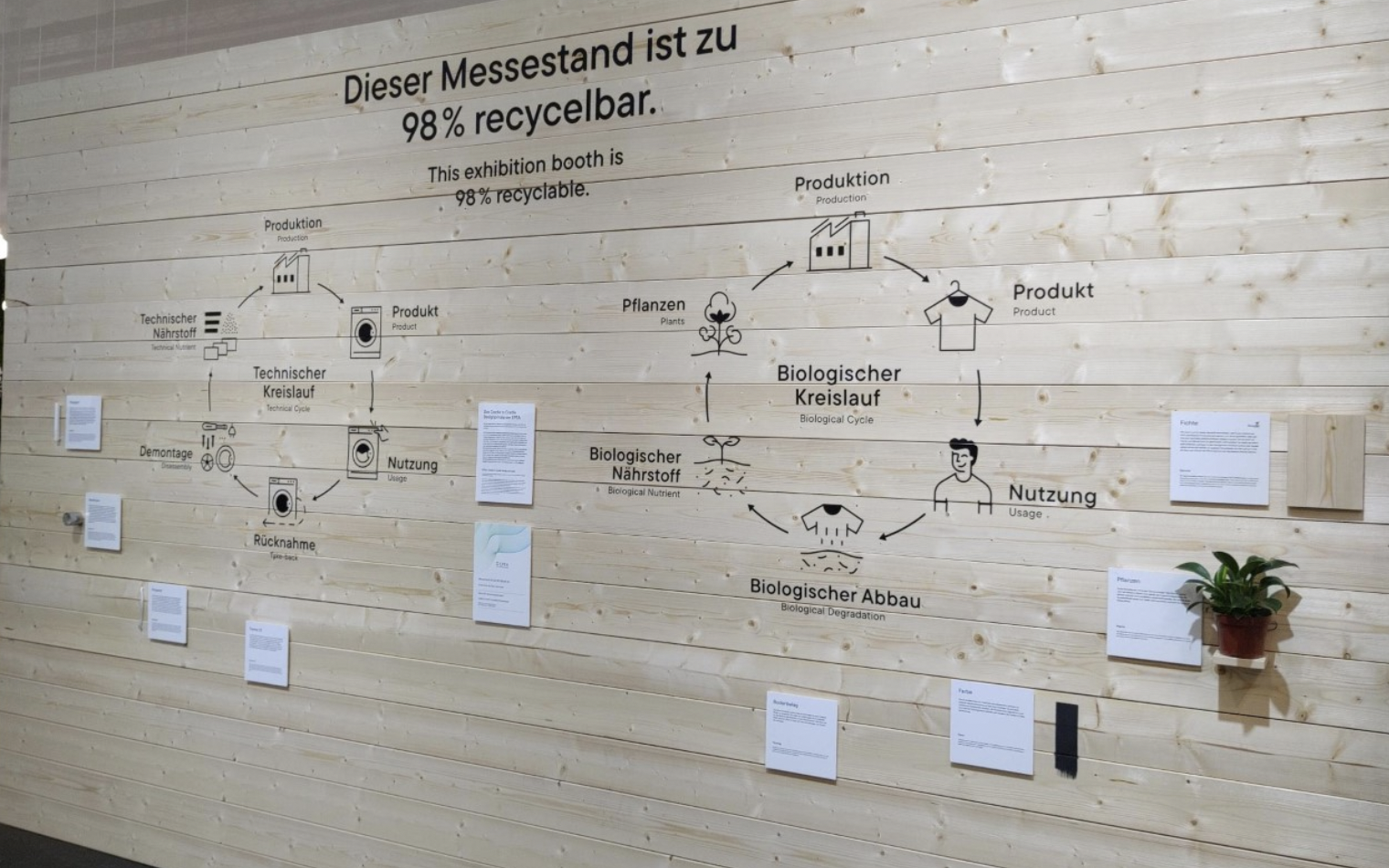

Circular strategies

pv magazine’s UP Initiative has been focusing on sustainability in the solar industry since 2019. While we have addressed issues like PV module recycling, green finance, sustainable electricity sourcing, and agri-PV, one item has not yet been on the agenda: the sustainability of conferences and trade shows.

The Covid-19 pandemic has pushed travel off the agenda for companies over the past two years; however, with the pace picking back up, one cannot ignore the giant carbon footprint of travel and the physical trade shows. Booths and giveaways, in particular, must be a green consideration, especially in the renewable energy industry.

This year, it was wonderful to stumble upon IBC Solar’s booth which has employed the Cradle-to-Cradle circular economy principles. Innovations include using paint from Keim, which is said to contain no harmful substances and can remain on wood for later use, and polyamid ropes as bracing for the ceiling elements, which can be either reused or recycled.

The Germany-based company also decided not to use extra flooring, instead remaining with the original trade show flooring, while using sustainably sourced spruce wood that is screwed rather than glued together. Following the exhibition, the wood will be donated to a local school to be used as fencing for a bee garden, Christina Pfeufer, director of marketing and corporate communications, told pv magazine. Moreover, the aluminum structures will go back to the booth builder for reuse, and the employees have been encouraged to take the decorative plants home with them. She added that the booth design was not more expensive this year compared to past versions.

In terms of its internal strategy, Julius Möhrstedt, head of corporate sales services, said IBC Solar is gearing up to publish its first sustainability report soon.

Let’s hope we will see more of this innovation at future events!

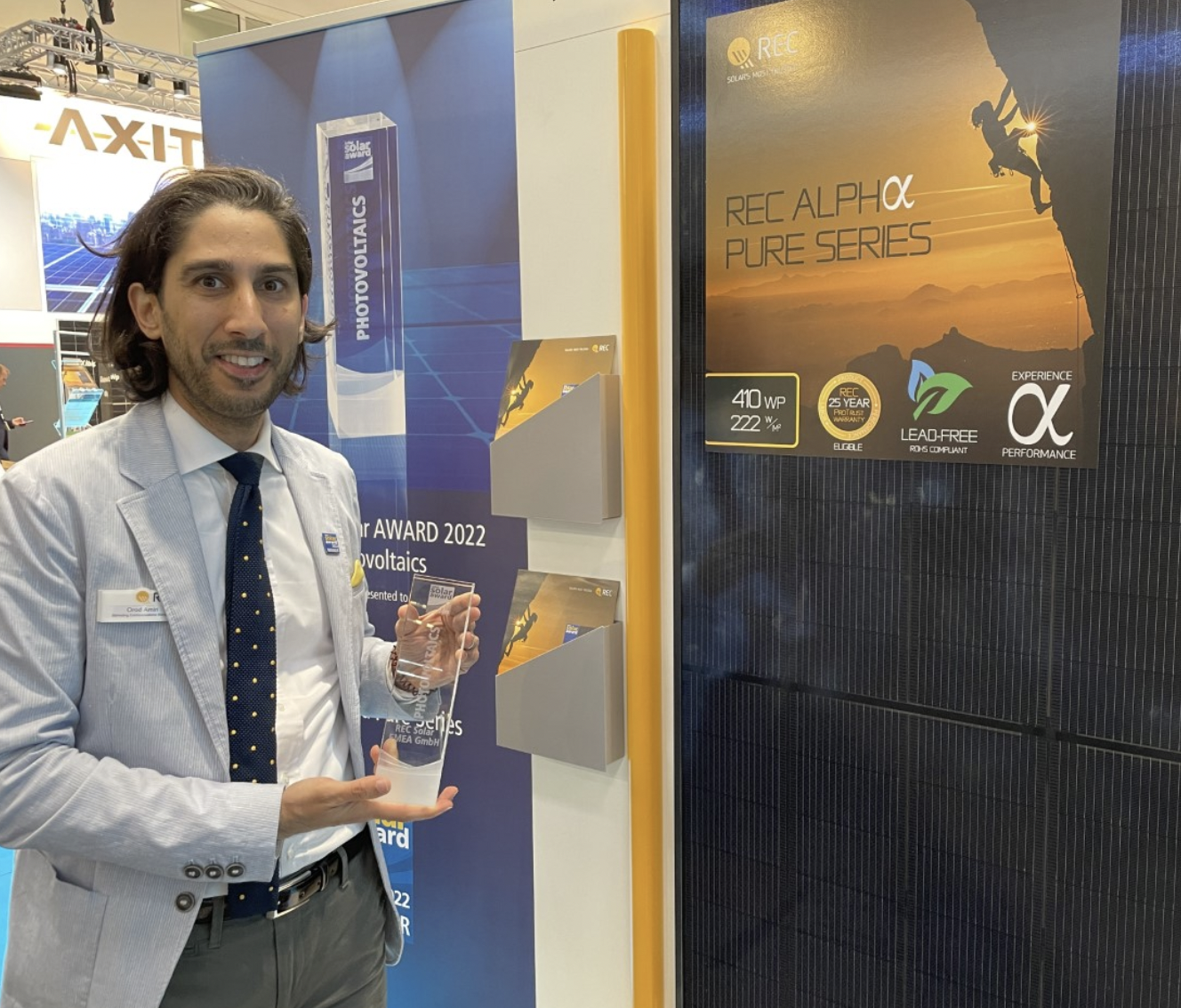

Breaking: Intersolar trophies have arrived

There’s nothing quite like an award winner proudly holding a trophy aloft. Unless, of course, the trophies are still in transit.

The Intersolar, ESS, Outstanding Projects, and Smart Renewable Energy award winners weren’t left empty handed at the awards ceremony on Tuesday, but they did have to wait until today for the physical trophies to arrive. But arrive they have!

pv magazine stopped by the REC booth to find company employees proudly grasping their Intersolar Award this year, for its new REC Alpha Pure Series. The module boasts a series of innovations, the most outstanding of which is that it is now entirely free of lead.

The robots have arrived – complete this survey to help shape the future of O&M automation

The maturity of robotic module cleaning was on display in hall A5 at Intersolar this year, with robots of all shapes and sizes crawling, brushing, sweeping, and washing the booths.

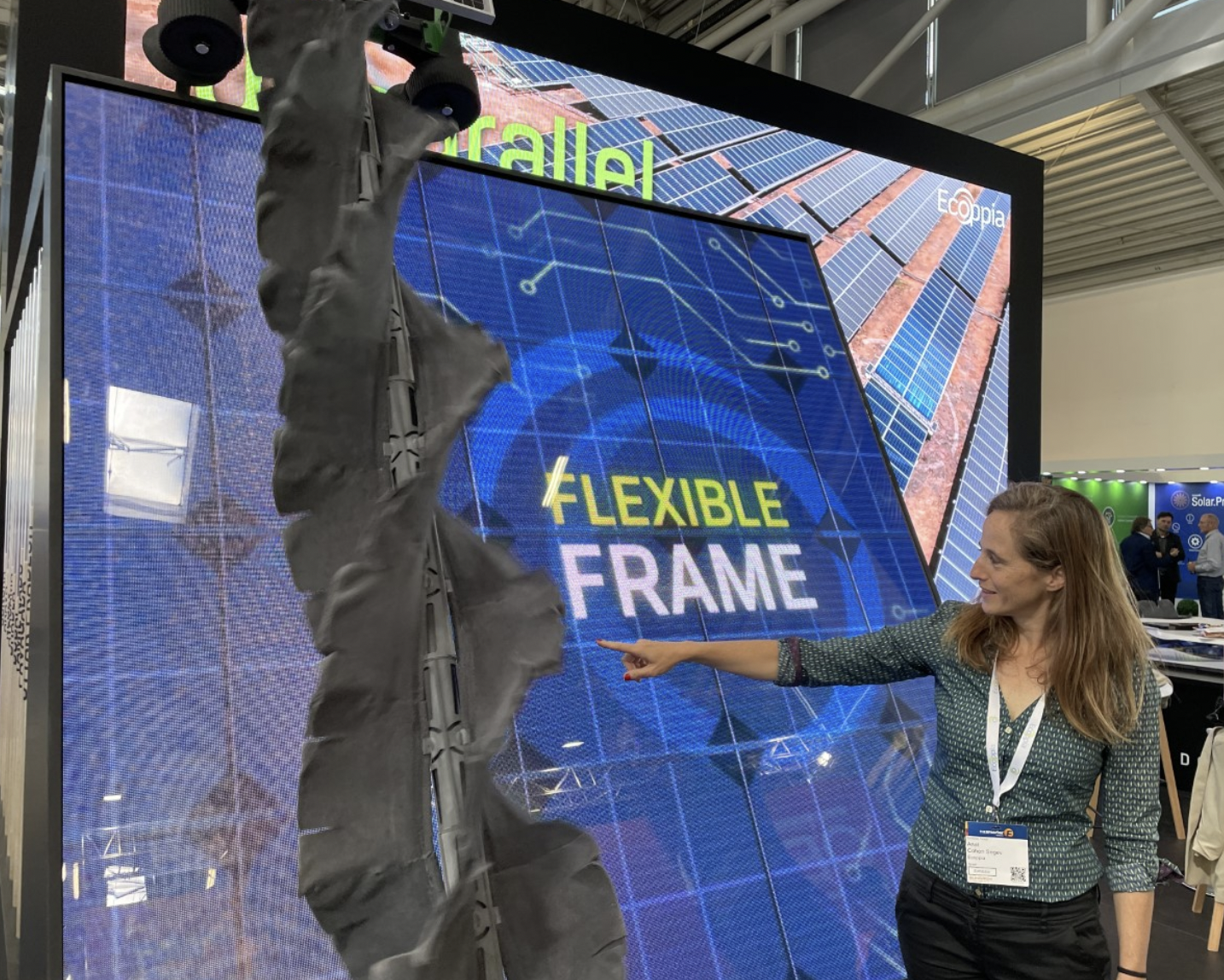

One of the most striking solutions was from Israel-based Ecoppia, which had both its T4 and its new H4 autonomous robots demonstrating their effectiveness. A major challenge, said Anat Segev, Ecoppia’s VP marketing, was stopping people from interfering with the robots’ work.

“Please don’t touch signs don’t seem to be enough,” said Segev.

The H4 robot was launched at Intersolar this week, and Segev said interest in the larger robot was high.

“A lot of people are stopping by and people that have heard the T4 and want to know what is coming next – and they can see that the H4 builds on our experience in providing autonomous cleaners that are robust, reliable and proven.”

The automation of O&M is presenting as a significant opportunity, allowing projects to boost power generation and implement preventative maintenance regimes.

“With the sites getting larger and more remote, automation is the key for effective and efficient O&M,” said Segev. “O&M is the key now to make projects profitable and optimizing O&M is what everyone is struggling with.”

pv magazine is partnering with Ecoppia to take the temperature of the O&M marketplace and to understand what the opportunities and challenges are in automating module cleaning and monitoring PV project health and performance. The survey takes less than five minutes and the results will be shared with the PV community in a feature article in the September 2022 edition of pv magazine global.

https://www.surveymonkey.de/r/YGZCD3R

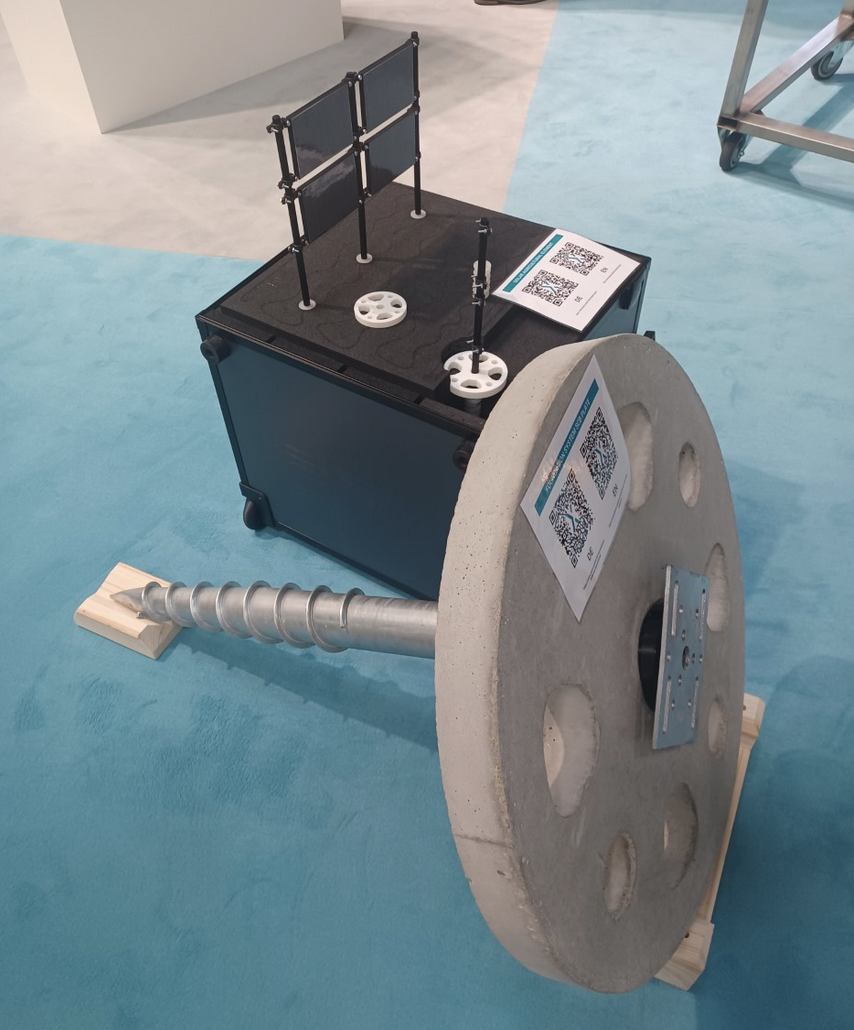

Earth screw, not vice versa

Engineering innovator paXos has developed a solution for vertical agri-PV systems that reduces vulnerability to wind. As Project Manager Marius Nennewitz told pv magazine, high winds put an enormous amount of pressure on the bend point at the base of the stanchion. The solution paXos has come up with is called the “Solar Agricultural Element Foundation System,” or more simply, the “Earth Screw” (pictured).

Inspired by the root systems of trees, which grow horizontal surface roots to stablize themselves against the pulling force of winds, the Earth Screw combines a screw with a rigid concrete slab that rests just below the top soil to absorb bending forces. Nannewitz said the solution has proven 85% more effective at resisting wind – a figure he says improves with the thickness of the plate.

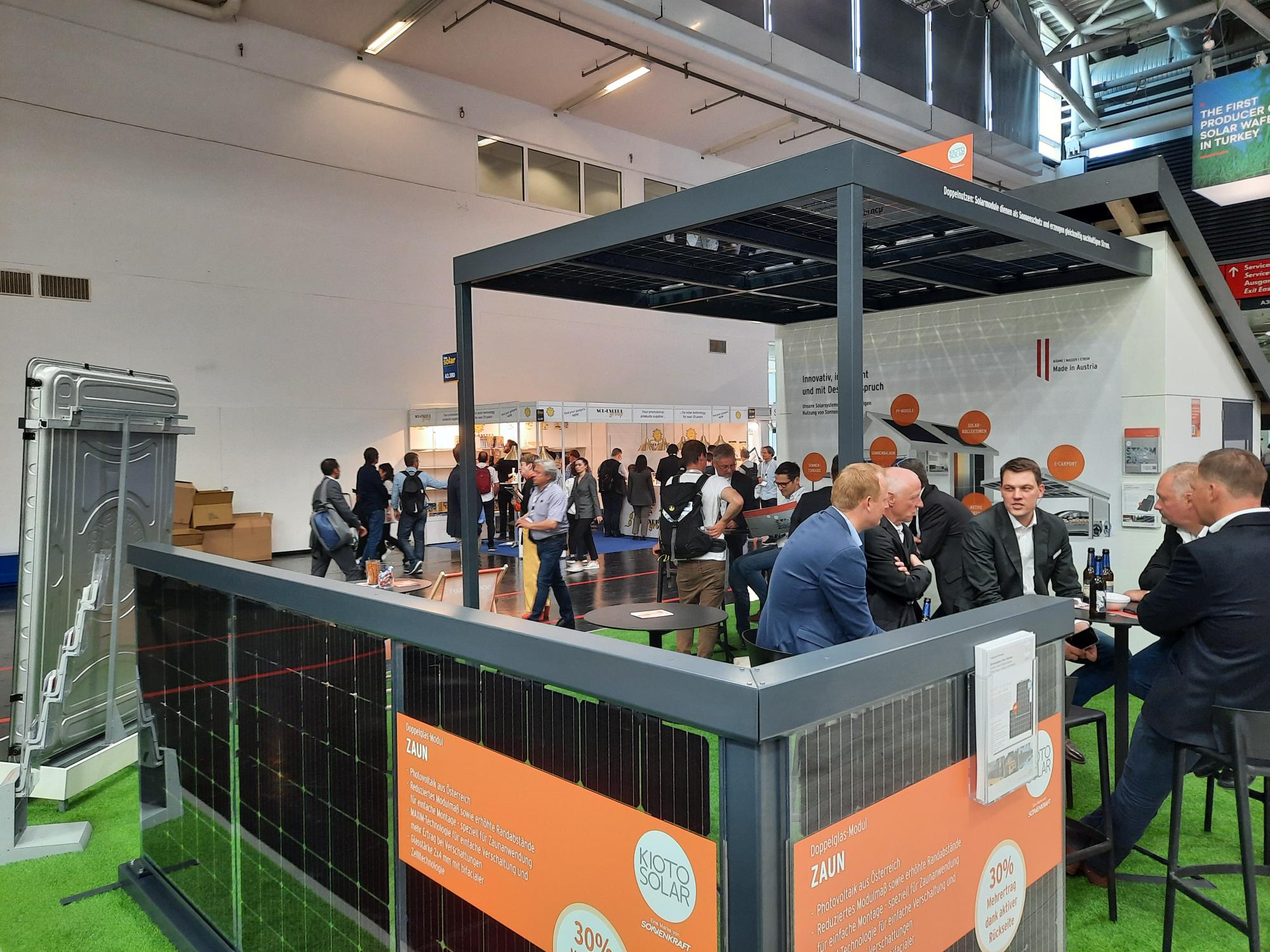

A selection of specialties

Austrian solar manufacturer Sonnenkraft has recognized that there is not only space on rooftops. With a wide range of special modules, it satisfies the demand for solar power from all kinds of other spots, including canopies and carports that can be beautifully covered with semi-transparent glass-glass modules. The building approvals required in Germany, which ensure that overhead modules will not injure anyone if they break, have already been granted.

There are also black glass-glass modules or stylish modules with coloured glass in delicate brown or blue tones for the façade. This reduces the solar yield by around 10%, Dajana Scherr, head of marketing for Sonnenkraft, told pv magzine‘s Cornelia Lichner when she visited the stand.

Is there also room on the balcony? One or two socket modules will definitely still fit. The two-piece set is priced from €1,299 ($1,350), including the mounting kit and PV inverter.

Even fences offer options for solar power. Sonnenkraft produces smaller glass-glass module formats especially for this purpose. The technology for module production in Austria comes from domestic supplier Kioto Solar, which Sonnenkraft bought in 2019 and integrated into the company. This know-how is developing further into a new half-cut module, which is also exhibited.

QCells introduces its Q.HOME CORE

Proving popular at the busy QCells booth has been the new Q.HOME CORE energy storage solution. The system is available in two versions; hybrid and AC-coupled, but it is the hybrid H4 version that is being displayed here at Intersolar Europe.

The Q.HOME CORE H4 consists of a 4.6 kW hybrid inverter and a battery pack of 6.86 kWh, and with the Q.SAVE, which is the battery pack of the Q.HOME CORE, the system is scalable with the option to increase the storage capacity by 6.86 kWh increments, up to 20.5 kWh – which is enough to easily cover the needs of most households.

The Q.HOME CORE H4 is perfect for markets such as the UK and France thanks to its easy configuration with any new solar installation. With an embedded PV-generator, hybrid inverter, two MPPT trackers and a maximum voltage of 800 V per tracker, this intelligent, attractive battery pack promises to be a cool and reliable addition to any household eager to take a cleaner grasp of their electricity bills.

FPV rising in the pecking order

Canada-based Intech Clean Energy is prioritising ease of transport, ease of installation, and ease of maintenance for its floating PV (FPV) solution. Starting with its simple two-screw solution (pictured), in which the nut is installed prior to shipping so that installers need only insert and turn the screw, the floaters also possess collapsible panel rests for ease of transportation.

Project engineer Christoph Vollmer told pv magazine one such shipment is currently on its way to a chicken farmer in Queensland, Australia, who is particularly buoyed by the added FPV benefits of reduced water evaporation and algae growth. “Unlike competitors,” said Vollmer, “you can access each panel on our floaters for ease of maintenance, and the orientation can be adjusted, a bit like a chessboard, for south or, as in Australia, to the north.”

Recap from Days 1 & 2

Over the past two days, the pv magazine team has scoured the halls of Intersolar, searching for the latest PV and energy storage trends, innovative new products, market predictions, and hot gossip.

We've covered everything from animated debates at the green hydrogen forum, the women at Sonnen, and the philosophy of Reinhold Messner, to plug and play solar panels you can install yourself.

Read all about:

We also covered a number of new Intersolar announcements, including:

- Hanwha Q Cells to build US solar module factory, expand cell capacity in South Korea

- Meyer Burger CEO Gunter Erfurt talks solar tiles

- Gamesa Electric presents new central PV inverter

- Stackable dual-voltage battery from Weco

- Terracotta solar tiles for historical buildings

Make sure you stay tuned for more news from the final day of the show!