While its abundance and high gravimetric capacity make it a good fit for highly efficient metal ion batteries, the use of silicon as an electrode material has been limited. Specifically, the adoption of silicon anodes in lithium-ion batteries has been held back by their mechanical instability, which arises from uncontrolled volume expansion upon lithiation, the process of combining with a lithium-ion, and the subsequent formation of an unstable solid-electrode interface.

Presently, nanostructured silicon is most often explored as a solution to these issues, but it comes with it a set of drawbacks. They include supply gap, the difficult and expensive synthesis process, and the threat of fast battery dry-up. However, moving from nanostructured silicon to otherwise cost-effective and user-friendly micron silicon particles (SiMPs) only amplifies the aforementioned problems. But now, researchers from the Japan Advanced Institute of Science (JAIST) believes they have found a solution to the issues plaguing SiMPs.

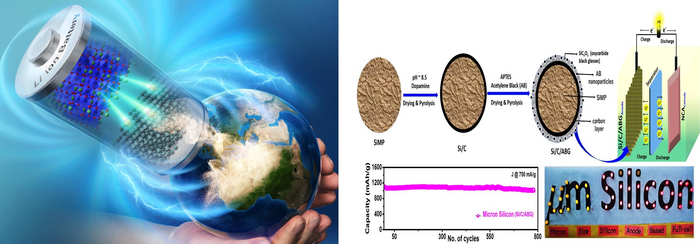

The team described their findings in Journal of Materials Chemistry A. They reported a holistic approach to synthesizing novel highly resilient SiMPs consisting of black glasses (silicon oxycarbide) grafted silicon as anode material for lithium-ion batteries.

“Silicon nanoparticles might provide increased effective surface area but that comes with its own drawbacks like increased consumption of electrolyte as well as poor initial coulombic efficiency after a few cycles of charging and discharging. SiMPs are the most appropriate, low-cost, and easily available alternatives, especially when combined with materials that have exceptional structural properties, such as silicon oxycarbide black glasses. Our material is not only high performing but also conducive to scale opportunities” said Prof. Noriyoshi Matsumi.

The team designed a core-shell type material with a core made up of SiMP, coated in a layer of carbon. They then grafted the silicon oxycarbide black glasses on as the shell layer. The prepared material was used in an anodic half-cell configuration to test its ability to reversibly store lithium under different potential windows. It demonstrated great lithium diffusion ability, reduced internal resistance, and overall volumetric expansion.

The superior electrochemical properties of this new material were further established by the 99.4% retention of energy capacity, even after 775 cycles of charging and discharging. In addition, the material also exhibited great mechanical stability throughout the testing process, the researchers said.

The JAIST researchers have also reported the successful integration of black glasses grafted silicon microparticles as a negative electrode material in a full-cell when paired with a commercially available lithium nickel cobalt aluminium oxide (NCA) cathode.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.