A group of scientists from the University of California and the University of Richmond in the United States has created high-temperature stable emitters that can reach temperatures of over 1,800 C and may reportedly enable “the next generation of record efficiency lab-scale TPV systems.”

“Our finding presents a novel pathway for designing photonic structures that can operate at ultra-high temperatures and could enable,” the researchers said. “All that while simultaneously paving the way for their commercialization due to the reduced complexity of the structures.”

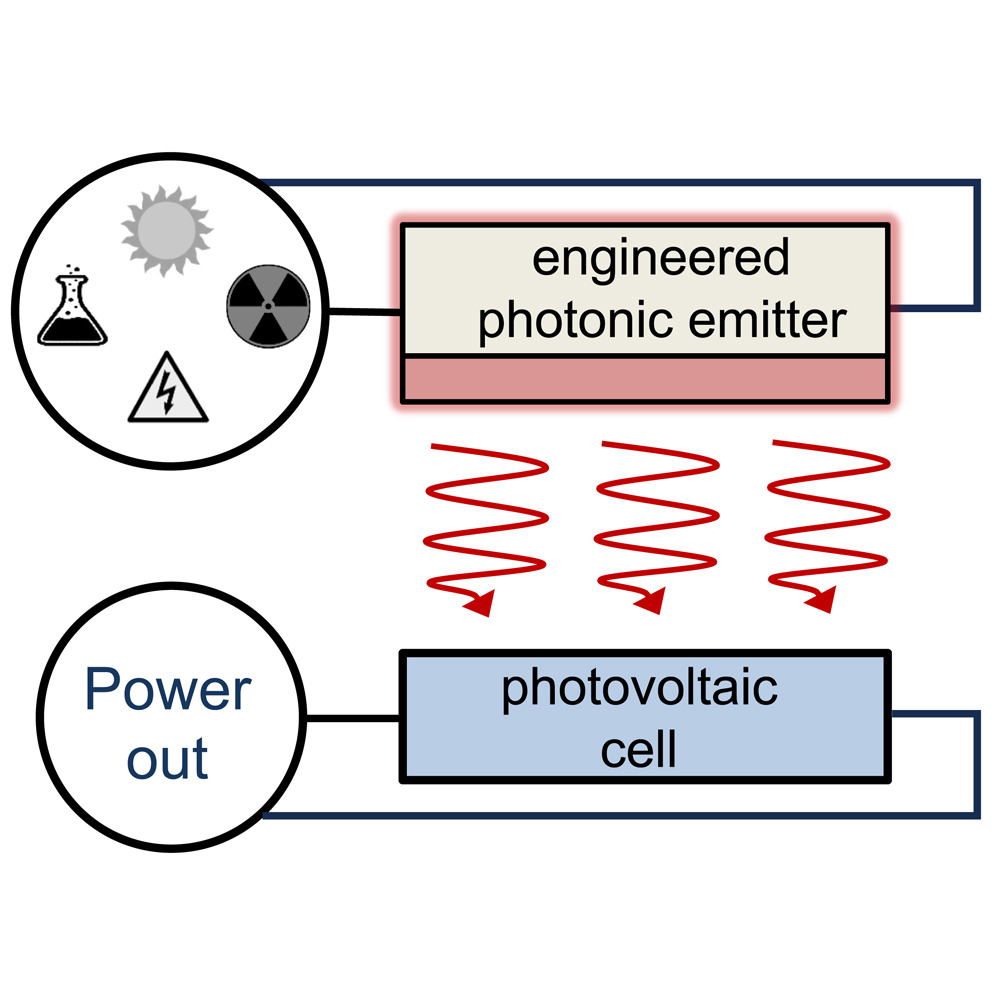

Solar thermophotovoltaics (STPV) is a power generation technology that utilizes thermal radiation to generate electricity in a photovoltaic cell. An STPV system consists of a thermal emitter that can reach high temperatures, near or beyond 1,000 C, and a photovoltaic diode cell that is able to absorb the photons coming from this heat source.

This technology has raised a strong interest among scientists in the past decades, as it is able to capture sunlight in the entire solar spectrum and has the technical potential to beat the Shockley-Queisser limit of traditional photovoltaics. The efficiencies reported so far, however, are still too low to make it commercially mature, as STPV devices still suffer from a series of optical and thermal losses.

The group combined 2,809 coating/substrate pairs and calculated the ideal photonic emitters. Those emitters have a tailored emission spectrum for TVP purposes, while also maintaining thermal stability in temperatures beyond 1,800 C. It also examined the combination of 53 materials with melting points above 2,000 C.

The scientists calculated then the heat-input-to-power-output efficiency of the combinations of all of those materials as either substrate or emitter coatings. They also marked the combinations with phase equilibria and low thermal expansion mismatches.

“Phase equilibria define whether the combined solid materials can co-exist until melting without forming a solid solution or an intermediate compound,” the academics explained in the paper.

Thermal expansion mismatches refer to the differences in how materials expand or contract when exposed to temperature changes.

Popular content

The research group analyzed the emitters with different TPV cells based on different configurations: indium, gallium, arsenic and antimony (InGaAsSb); indium, gallium and arsenic (InGaAs); germanium (Ge); gallium and antimony (GaSb); and crystalline silicon (Si).

The academics found that the most promising combinations under inert environment applications were those based on InGaAsSb, with an emitter made of a Hafnium diboride (e-HfB2) substrate and a 144 nm thick boron nitride (BN) coating. The STPV cell is able to generate 19.8 W/cm2 of power.

“Our results illustrate that design choices that have enhanced emitter-to-cell spectral matching, via thin films, can lead to a substantial gain in performance, enabling a figure-of-merit (FOM) of over 45% for InGaAsSb-, InGaAs-, Ge-, and GaSb-based TPV system and 33% for practical Si cells,” they stated in the paper.

The research has also tested the emitters in vacuum conditions. The aim was to avoid sublimation or degradation of the bilayer emitter under high temperatures. In a vacuum, one of the most promising combinations was of an InGaAsSb TPV cell and emitter made of HfB2 as a substrate and a 416 nm coating of boron carbide (B4C). The FOM in this case reached 46.7% and the electrical power generated by the cell was 7.52 W/cm2.

“Our framework also demonstrates the possibility of designing metamaterials for specific applications in high-temperature photonics via optimization and machine learning,” the researchers concluded. “We foresee this strategy enabling a pathway for TPV with >50% power conversion efficiency and applications to other high-temperature systems and thermal devices with improved functionality and stability.”

Their findings were presented in the study “Photonics roadmap for ultra-high-temperature thermophotovoltaics,” published this month in Joule.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.