Scientists at Osaka University have developed a robotic system that uses machine learning to automate the assessments of novel solar cells.

The researchers described their findings in “Exploration of Solution-Processed Bi/Sb Solar Cells by Automated Robotic Experiments Equipped with Microwave Conductivity,” which was recently published in JACS Au. They said the robot can perform photoabsorption (PA) and photoluminescence (PL) spectroscopy, optical microscopy, and white-light flash time-resolved microwave conductivity (TRMC) tests.

“Current solar cells are made of inorganic semiconductors containing silicon and gallium, but next-generation solar cells need to reduce both cost and weight,” said researcher Chisato Nishikawa. “However, the wide range of elements and process parameters impede the rapid exploration of vast chemical spaces.”

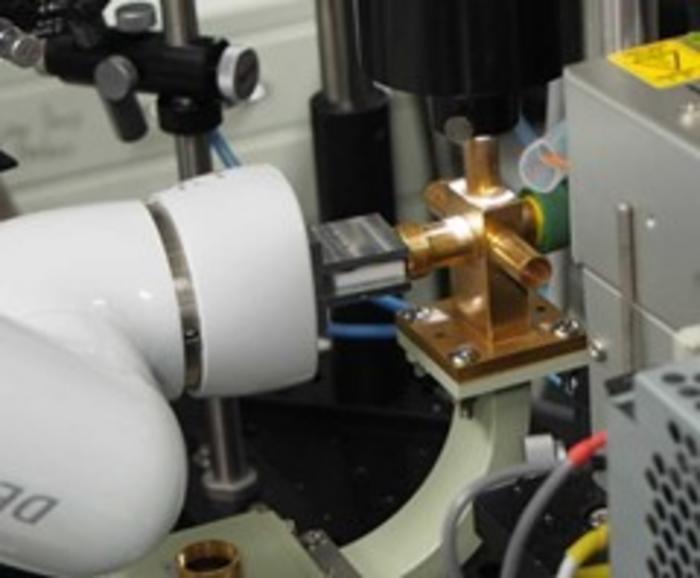

The robotic system is controlled by in-house software. It includes a handling robot, PA and PL spectrometers, TRMC optics and electronics, an optical microscope, and a sample cartridge.

“The TRMC comprised an Xe-flash lamp, a signal generator, a resonant cavity at around 9 GHz, a microwave circuit, a pulse generator, and an oscilloscope,” the scientists said.

The results are automatically analyzed through the creation of an optical microscopic image.

“In recent years, machine learning has been very helpful in better understanding the properties of materials,” said researcher Akinori Saeki. “These studies require vast amounts of experimental data, and combining automated experiments with machine-learning techniques is an ideal solution.”

The research team said a typical cycle of measurements takes five minutes. To verify the accuracy of the new robot, the TRMC transients were measured 50 times over the identical sample. That process reportedly showed high reproducibility, with a standard deviation of 1.99% for the photoconductivity maximum.

Rhe academics used the robot to evaluate different thin-film semiconductor samples.

“We tested 576 films of quaternary element-blended wide-bandgap Cs−Bi−Sb−I semiconductors with various compositions, organic salt additives (MACl, FACl, MAI, and FAI, where MA and FA represent methylammonium and formamidinium, respectively), and thermal annealing temperatures,” they explained.

Among all tested films, the robot found the maximum power conversion efficiency to be 2.36% with a composed ratio of 1:0.5:0.5. The related photovoltaic material was created with MACl organic salt additives and thermal annealing at 200 C. Compared to a reference film without the additive, the efficiency was 0.68% higher.

“The unique automated robotic experiments and findings presented in this study will benefit scientific research on PV materials by accelerating the discovery process,” the research group concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.