Researchers from Romania’s Transilvania University of Brașov have investigated the impact of particularly thick layers of dust on the performance of different PV technologies.

“If the effects of climate change escalate, resulting in less rainfall and more frequent sandstorm events originating from the Saharan region, then extreme scenarios are very likely to occur in Europe,” the research's corresponding author, Abubaker Younis told pv magazine.”Logically, the majority of dust is expected to settle in Southern European countries, with occasional dust storm events reaching Central Europe.”

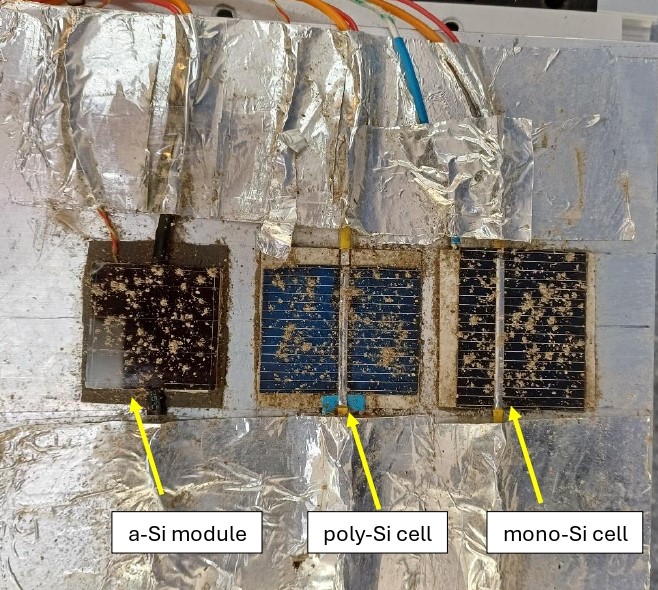

The scientists conducted their tests on amorphous silicon (a-Si), monocrystalline and polycrystalline panels, on which they simulated relatively extreme dust conditions. They used a mini a-Si module with dimensions of 30 mm × 30 mm, a monocrystalline panel measuring 41.6 mm × 33.9 mm, and a polycrystalline device with a size of 33 mm × 40.4 mm. On them, they deposited natural dust collected from the surroundings of the Eastern Romanian city of Brașov. The non-homogeneous layers were deposited using a sieve.

The academics tested the modules under varying conditions, in the lab, in the field, and under different irradiations. Furthermore, they compared their performance with that of reference modules without dust.

For the field test, they placed the modules on the rooftop of one of Transilvania University of Brașov’s campuses and took measurements once irradiation reached 800 W/m2, 900 W/m2, and 1,000 W/m2. The same irradiation levels were simulated in the lab experiment using a solar simulator.

Under all of those conditions, the modules were tested for I-V characteristics as well as front and back temperatures.

“The dust layer thickness averaged 25.8 μm (or 0.01936 μm mm-2) when formed on the mono-Si mini cell surface and 32.25 μm (or 0.02287 μm mm-2) when deposited on the poly-Si small cell surface,” they highlighted. “However, the same measurement technique, which relies on the emission of ultrasonic waves, was not applicable to the a-Si mini-module. This is because a metallic substrate is required for the gauge to function, and such a substrate is typically not part of the module composition in the case of a-Si PV technology.”

The research group found that the maximum drop in short circuit current and maximum power point between a clean and a dusty module happened in the scenario of the poly-Si mini-cell at 800 W/m2, outside and inside. In the field test, the short-circuit current decrease was 38.14% and 45.35% in maximum power point, while in the lab, it was 33.38% and 32.02%, respectively.

As for the temperature of the front surface, in the outdoor case, the polysilicon panel under 1,000 W/m2 irradiation displayed the most significant increase – of 3.7 C. In the indoor case, the largest temperature jump was 1.3 C, on the polysilicon module under 800 W/m2 and the a-Si module with 900 W/m2.

When calculating the rise in temperature of the back surface, the largest increase in the field was 2.3 C in the a-Si under 1,000 W/m2 case, and in the lab, it was the monocrystalline panel under the same irradiation, with 0.9 C higher temperatures compared to the clean module.

“It was observed that the outdoor setup yielded better results than the indoor setup due to the randomness and inconsistency in the latter’s results,” they emphasized. “This abnormality was attributed to the lack of a standard method for conducting laboratory-based experiments on dust deposition, which would reduce the impact of uncontrollable errors.”

Their results were presented in “Dust impact on electrical and thermal photovoltaic performance: Insights from field and laboratory experiments,” published on Energy Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

5 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.