Scientists at the Technical University of Denmark have built a prototype of a magnetocaloric heat pump (MCHP) intended for use in residential buildings.

“We are still working on system optimization and cost reduction, which can advance the real application,” the research's corresponding author, Jierong Liang, told pv magazine. “The system is mainly responsible for relatively low-temperature heating and can work well with PV, which is responsible for a higher temperature level.”

MCHPs use the magnetocaloric effect to perform heating and cooling. This effect consists of the cooling or heating of magnetic materials with the variation of an externally applied magnetic field. It is commonly utilized to develop highly energy-efficient cooling or heating systems that require no harmful refrigerants at all.

In MCHPs, the temperature changes through a variation of the magnetic field, with these caloric effects being employed to transfer thermal energy and produce heating or cooling power. All of these systems ar relying on an active magnetic regenerator (AMR) concept, where a heat transfer fluid is actively pumped through a bed of magnetocaloric material in order to transfer thermal energy to hot and cold side heat exchangers.

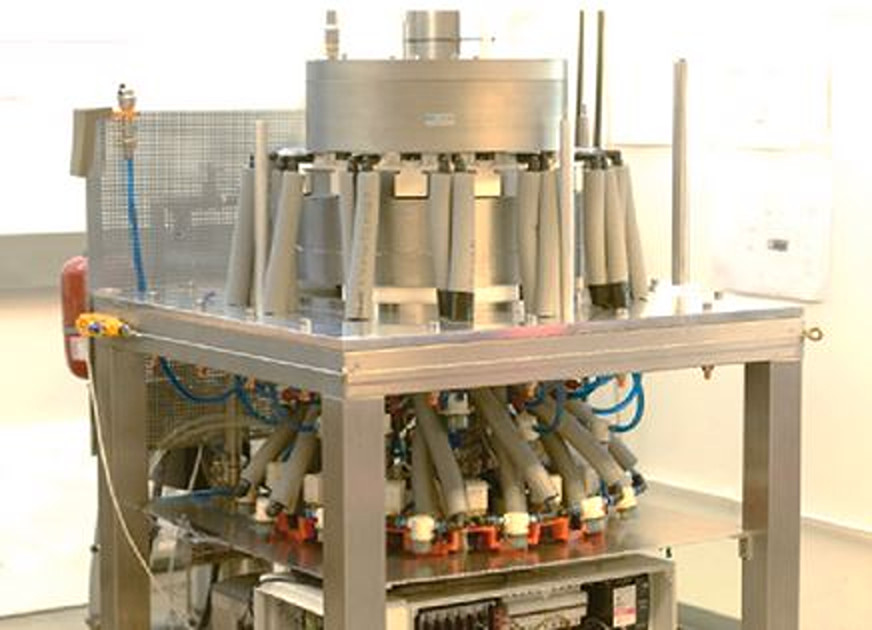

The group built a full-scale MCHP prototype with 13 parallel AMR beds filled with 4.4 kg of pure gadolinium (Gd) particles as a magnetocaloric material (MCM). The system uses a computer-controlled solenoid valving system to manage both inter-AMR flow imbalances and intra-AMR flow imbalances in real time. It also features a rotary two-pole permanent magnet with a maximum flux density of 1.46 Tesla.

“The MCMs act as both heat storage heat exchanger and being heated and cooled by the ramping-up and ramping-down magnetic field, respectively,” the scientists said. “As the MCM is magnetized, heat transfer fluid is pumped through the AMR bed in the cold-to-hot direction, transferring heat from the MCM to the heat transfer fluid, and vice versa during demagnetization.”

They also explained that the control of the displaced volume of fluid for each AMR and each blow is achieved by tuning the local blow fraction by adjusting the opening timing of each solenoid valve, without the need for additional components. “Different measurement-feedback control strategies, including AMR cold outlet temperature, AMR hot outlet temperature, and both as control feedback parameters, are explored to understand the trade-off between multi-bed operation controllability and device economics,” they added.

The system also uses a fluid flow system based on solenoid valves, a pump, check valves, and manifolds, which enables continuous circulation of the heat transfer fluid while facilitating reciprocating flow in each AMR bed.

Named MagQueen, the multi-bed MCHP prototype was designed to meet the heating demands of a low-energy single-family house in Denmark. Two control strategies, namely measurement feedback control and model predictive control, were used to optimize its performance.

“Model predictive control offers a solution to expedite control convergence by providing an initial valve setting estimation for all valves in a single step,” the group emphasized. “Integrating model predictive control frameworks with machine learning algorithms can help identify potential system failures, such as component aging, in advance.”

The analysis showed that, in the modeling, uneven flow resistance, porosity, and magnetocaloric effect negatively impacted the heat pump efficiency. Measurement feedback control, however, was able to improve heating capacity by 36.9%.

“Model Predictive Control achieves positive results for major outliers, demonstrating the potential for faster control convergence, while addressing overshooting for minor outliers requires further refinement,” the team further explained. “The control convergence speed is estimated to be seven times faster compared to the measurement feedback control strategy.”

The researchers also found that model predictive control improves heating capacity by up to 30.9% and coefficient of performance (COP) by up to 10.7%. By accommodating uneven magnetocaloric effects, it also improved COP by around 3.5%.

“Despite advancements in magnetocaloric heat pumps, challenges remain, particularly in adapting control strategies to multi-layer regenerators with varying Curie temperatures and magnetocaloric effects,” they said, referring to the future direction of their work.

Their findings are available in the study “Scaling up magnetocaloric heat pump for building decarbonization initiatives,” published in Energy. “The prototype costs were not yet estimated, as some components are oversized. As mentioned before, we keep working on cost reduction and hopefully can make it affordable in the future. We don’t have a plan for a field test so far due to the budget problem,” Liang concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Measured performance of 258 watts at a COP of 1.9