Terawatt scale by 2050

In a new paper published in the journal of Renewable and Sustainable Energy, renowned PV scientist Pierre Verlinden examines the solar industry’s trajectory towards the 70 TW of installed capacity that will be needed by 2050, as the best choice for meeting climate targets set out in the 2015 Paris agreement. Silver consumption and recycling, according to Verlinden, will be the biggest challenges in the years to come, as well as ensuring balanced growth and avoiding a major installation rush in the years close to 2050.

Best tech for intermediate-band solar cells

Researchers in Spain have analyzed the most important technologies for the development of intermediate-band solar cells (IBSC), a solar PV technology that was conceived to exceed the Shockley–Queisser limit. They identified four established technologies that are currently being adopted to manufacture IB materials and IBSC prototypes. Their future goal is to find the appropriate material to fabricate cheap and very efficient IBSCs.

Omnidirectional anti-reflective coating from Canada

Founded in 2018, Edgehog Advanced Technologies has developed an omnidirectional anti-reflective glass for solar panels, which increases their production, especially at the start and end of the day.

The weekend read: Something truly new

You can try to succeed by making a better version of your competitors’ product, or you can try to do something completely new. NexWafe has chosen the second path. It is developing plans to manufacture wafers for high-efficiency solar cells in Bitterfeld, Germany, that are produced more sustainably and at lower cost than any other products available today.

Chinese PV Industry Brief: PV additions hit 18.7 GW in January-September period

Just as the nation posted strong deployment figures, two major module manufacturers reported solid earnings for the nine months to the end of September.

Perovskite-based solar window tech from NREL

NREL’s new solar window darkens in the heat of the sun, producing electricity via embedded perovskite film. The tech is based on formamidinium-based metal halide perovskite, an inherently thermochromic material exhibiting significant optical changes.

REC Silicon could restart poly production at Moses Lake

The Norwegian polysilicon maker has been been frozen out of the Chinese solar market by political tensions between Beijing and the U.S. and mothballed its Washington State production line last year. However, two recent business agreements could change all that.

Plasma passivation process to cut silicon cell costs

Scientists in Saudi Arabia have developed a new passivation process for n-type silicon solar cells, which they say could offer a simpler, lower-cost alternative to current processes used in manufacturing. The group fabricated wafers using this process with promising results, and now plans to integrate the process into a full silicon cell.

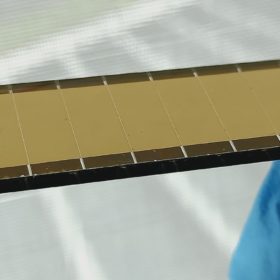

Mini perovskite solar panels with 18.4% efficiency

Researchers in Singapore have developed a 6.4 cm2 solar module based on co-evaporated methylammonium lead iodide (MAPbI3). They claim that the panel is a step forward in the industrialization of perovskite mini-modules.

US startup wins $7.6 million in funding for ribbon silicon furnaces

Leading Edge Equipment Technologies falls in the kerfless solar wafer or direct solar wafer category. Its “drop-in” manufacturing tech cuts wafer costs by 50%, drives up commercial PV power by 7%, and reduces manufacturing emissions by 50%. It’s the emissions piece that may be winning over investors.