Chinese PV Industry Brief: Two major deals for PV production equipment

JSG has sold several ingot furnaces to Shuangliang Eco-Energy and Jinchen Machinery will provide Yingli with production equipment totaling 3.5 GW.

Gallium arsenide nanowire solar cell with 7.7% efficiency

Norwegian scientists have developed a gallium arsenide (GaAs) nanowire solar cell that can be used as a top cell in a dual tandem cell with a bottom silicon cell. The device is claimed to be the most efficient single-junction GaAs nanowire solar cell grown on a silicon substrate so far.

New laser-cutting system for half-cut, shingled PV cells

German manufacturer 3-D Micromac said it has developed a new machine that can produce more than 6,000 wafers per hour. It is suitable for solar cells with temperature-sensitive coatings, or depositions such as heterojunction devices.

Quantum dot solar window with 3.6% efficiency

U.S. manufacturer UbiQD has developed a solar window with laminated glass and luminescent solar concentrators, based on copper indium sulfide and zinc sulfide quantum dots. It is now testing pilot installations in Nevada.

Floating PV tested at water treatment plant in South Africa

The pilot system was built with the Hydrelio floating platforms developed by French specialist Ciel&Terre. The project performance will be evaluated during a full seasonal weather cycle.

End-of-life management of solar PV waste in India

A new study proposes an ‘extended producer responsibility’ regulatory framework for end-of-life solar PV management in India.

Which crops pair well with solar?

Rapidly falling prices of solar panels have created an impetus for the construction of solar fields, which are often perceived as competing with crop production.

How PV performs close to radio, TV antennas

Researchers in Kenya have analyzed the performance of an off-grid PV system located near an isotropic antenna as an emitting source.

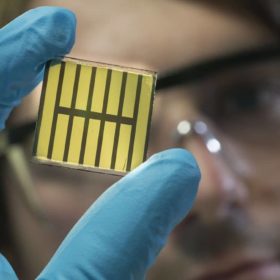

Established thin film processing for 18%-efficient perovskite mini-modules

Scientists in Germany applied vapor-based deposition techniques and laser scribed interconnection – both well established processes in existing thin-film solar manufacturing – to fabricate perovskite mini modules. The group achieved a maximum efficiency of 18% for a device measuring 4cm². Relying on these processes, they say, could simplify processing and reduce losses associated with scaling up to commercial-sized devices.

Growatt unveils EV chargers for residential and commercial applications

The charging stations are available as both AC and DC chargers. They are compatible with all branded electric vehicles and PV modules.