Indian manufacturer orders 1.2 GW solar production line

Gujarat-based solar panel maker Solex Energy will buy the production equipment from China’s Jinchen Machinery. The company also has plans for a cell line.

A repair tape for cracked backsheets

Backsheet failures have plagued the industry, causing hefty financial burdens to many asset owners. DuPont has launched a product it says allows for easy repair of modules.

Cadmium-free kesterite solar cell with 9.82% efficiency

Researchers in South Korea have fabricated a cadmium-free heterojunction kesterite solar cell based on a zinc sulfide oxide Zn(O,S) buffer layer. They used a one-minute ammonium sulfide (NH4)2S treatment process for surface cleaning and passivation of the cell’s CZTSSe absorber.

Nepal wants to support renewables up to 1 MW through viability gap funding

Nepal’s Alternative Energy Promotion Centre (AEPC) is seeking proposals for renewable energy projects not exceeding 1 MW in size.

Italy installed 152 MW of PV in Q1 2021

The country installed 35 MW more solar in the first three months of the year than it did in the same period a year earlier. Its cumulative capacity surpassed 22.1 GW by the end of March.

Cleaning solar modules with sand and wind, on Mars

NASA scientists have partially cleaned up the solar modules of the Insight lander operating on Mars, by using grain sands collected nearby and trickling them on the panels during the windiest time of the day. This handmade technique has made it possible, according to them, to increase the PV array’s yield of about 30 watt-hours of energy per ‘sol,’ or Martian day.

Australian research prompts rethink on silicon heterojunction cell production

Defect engineering for silicon heterojunction solar cells has come a long way. But Matthew Wright, a solar researcher at the University of New South Wales, asks whether these proven efficiency gains could be applied more effectively.

Watch how this solar array will boost the International Space Station’s power capacity

The solar cells for the space station were provided by Boeing’s subsidiary Spectrolab.

Developing standards for solar & wildlife habitat

A group of researchers in the U.S. analyzed recent developments in efforts at dual land use projects, combining solar energy with habitat for pollinators and other wildlife. Based on recent projects and studies, they offer a list of best practices for developing the habitats; and warn that without careful oversight the promising concept could amount to little more than greenwashing.

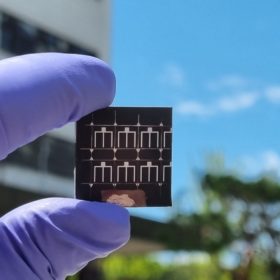

Four-terminal III-V solar cell with 32.57% efficiency

Scientists at the US National Renewable Energy Laboratory have simulated a III-V solar cell by stacking gallium arsenide films onto interdigitated back contact silicon solar cells with a glass interlayer. The scientists have already done some initial mini-module integration work, but significant size scaling will ultimately be needed to reach commercialization. The cell currently has an active area of 1 cm2.