Eindhoven-based startup LionVolt has completed the acquisition of AMTE Power’s business and assets in Scotland, including a battery cell production line in Thurso.

Due to ongoing delays in securing the necessary funds, AMTE Power – an Oxfordshire-based developer and manufacturer of lithium-ion and sodium-ion battery cells – went into administration in December. However, FRP Advisory ran an accelerated mergers and acquisitions process and said last week that it had completed the sale of the company’s business and assets to LionVolt.

The sale enables the battery production facility to be repurposed for producing LionVolt’s 3D technology and includes the transfer of 20 jobs based in Thurso. AMTE Power's remaining 15 employees in Milton, England, have been made redundant.

“The acquisition by LionVolt presented the best opportunity to secure jobs and fulfil our statutory duties to creditors,” said Richard Bloomfield, director of FRP Advisory and the joint administrator of AMTE Power Plc. “The transaction follows an exhaustive sales process and search for new investment. Critically, it preserves a large number of jobs and provides a continuation of battery cell manufacturing in Scotland.”

For LionVolt, the acquisition of the battery production site brings “new complementary capabilities to the company for its next phase of growth.”

Sandeep Unnikrishnan, the CTO of LionVolt, described the transaction as a “dream scenario.”

“It helps us mature our innovative 3D battery technology quicker by leveraging the manufacturing expertise from the team in Scotland, thereby reducing time-to-market,” said Unnikrishnan.

The acquisition comes hot on the heels of LionVolt’s announcement that it is building a pilot production line at the Brainport Industries Campus (BIC) in Eindhoven, the Netherlands.

LionVolt was spun off from the Netherlands Organization for Applied Scientific Research (TNO) in 2020 with a mission to develop and scale its 3D solid-state thin-film battery technology. The technology is said to deliver enhanced energy density, superior cycle-life, higher charging speed, and enhanced safety compared to conventional lithium-ion batteries and be particularly suitable for wearables and electric vehicle applications.

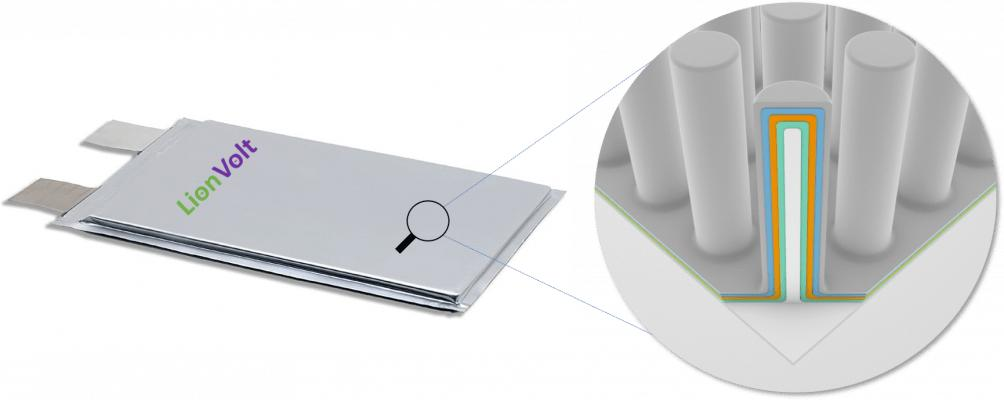

LionVolt's batteries are made by covering billions of pillars with thin layers of functional material, creating a 3D structure with a very large surface area and very short distances between both battery electrodes. Charging and discharging times are reduced, as the lithium-ions only have to travel a short distance.

The manufacturer said this approach enables the technology to overcome two major hurdles to its commercial rollout – the conformal coating of the full battery stack and the development of scalable manufacturing tools. The creation of the micropillar arrays is reportedly able to reduce the technological challenge of conformal coating, and the open and regular structure facilitates the deposition of consecutive layers.

LionVolt said its battery configuration is fully retrofittable into existing commercial formats and a production line can be set up in a very short time. Almost 80% of the supply chain needed to build a production line can be sourced locally, according to the Dutch company.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

AMTE specialised in both lithium and sodium ion cells – so does this Lionvolt deal end the sodium side of things completely? Or can/will Lionvolt’s solid-state tech be applied to and adapted for the production of theoretically much lower-cost solid-state sodium batteries – or can we really now realistically only depend on China and companies like CATL, BYD and HiNa to keep the cost-slashing sodium cell dream alive? As in: Build Your Dreams of a cost-crushing sodium revolution – but only in China?

Paul G