Researchers at France's National Solar Energy Institute (INES) – a division of the French Alternative Energies and Atomic Energy Commission (CEA) – have published a paper describing the technical features of the industrial-scale prototype of a silicon heterojunction (SHJ) module that was announced early last year.

“The paper explains all technical details and complementary results,” corresponding author, Timea Béjat, told pv magazine, noting that the team used an internal ECO PV tool for Life Cycle Assessment (LCA) studies to optimize PV module design for low environmental impact. Béjat also pointed out that a key result of the research was that the very low carbon designs could be achieved with technologies that are available today.

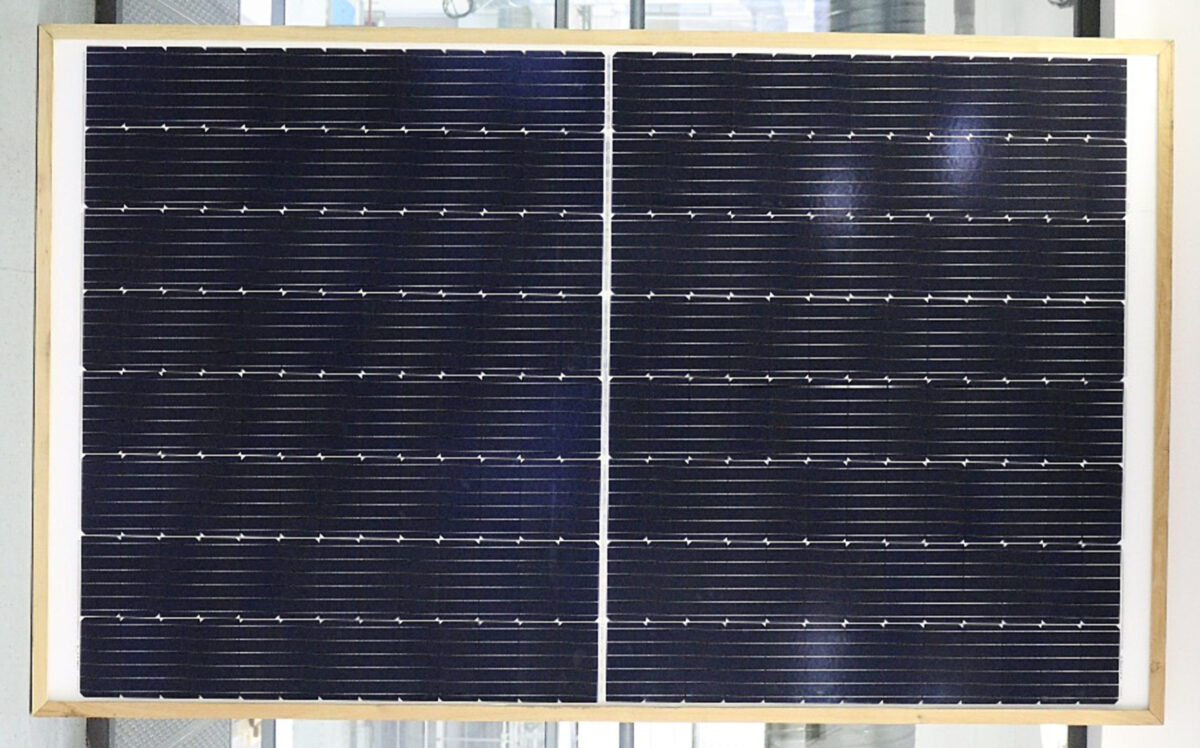

The scientists built the panel by using a CEA-INES pilot line. They used 130-μm M2 Czochralski wafers, vapor deposition, and transparent conductive oxide on both sides in a 6-busbar design cured at 200 C for 15 minutes. The cell bifaciality factor was in the range of 92%, noted the team.

“For a standard PV module, we identify the main steps to improve in order to reduce its environmental footprint,” the research team said. “This guided us to tackle the components with the highest impact on the carbon footprint, namely the wafer, glass front sheet and aluminum frame.”

At the cell level, the academics reduced the thickness of the wafers, which they claim were acquired via “the European value chain.” Metallization and cell interconnection were optimized to reduce silver consumption. At the module level, glass thickness was reduced, and conventional aluminum framing was replaced by a timber one packaged with a glass-backsheet configuration.

“In addition, we applied a ‘design for recycling’ approach for the choice of encapsulant and backsheet,” stated the team. “The combination of these innovations led us to the realization of a 566-W recyclable module using a tiling interconnection, cells with an average efficiency of 22.57% with a carbon footprint of 313 kgCO2eq/kWp.”

The prototype’s reported carbon footprint of 313 kgCO2 eq/kW is better than today’s conventional modules, which the team said varies between 700 kgCO2eq/kWp and 800 kgCO2eq/kWp.

Popular content

Purportedly, it is also lower than that of products from the “pioneering manufacturers” that have achieved sub-450 kgCO2eq/kWp modules, such as Korea’s Qcells, Belgium’s Bisol, Singapore’s REC, and Chinese manufacturers JinkoSolar, Trina Solar and Huasun, as noted by the research team in a non-exhaustive list.

As for the bill-of-material, the group said it took a “design for recycle” approach, which meant choosing a thermoplastic encapsulant, fluorine-free backsheet, and thin front glass. Moreover, the use of a timber frame instead of aluminum reduced the carbon footprint by more than 50–60 kgCO2eq/kWp, the researchers noted, but they also emphasized that the full qualification of this type of framing material is not complete.

The team concluded that by optimizing technical parameters and selecting environmentally friendly materials, it was “able to develop an eco-designed PV module with a very low carbon footprint,” and it showed the importance of finding a compromise between environmental impact optimization and module performance and durability.

Future work will attempt to improve performance and reduce material consumption, such as silver, both at the cell and module level, as well as integrate recycled material content at all stages of the value chain, according to the team. The team also plans to investigate alternative backsheet materials without aluminum and fluorine materials and to work on establishing the reliability of the alternative framing material.

The “Design for the environment: SHJ module with ultra-low carbon footprint” study was recently published in Progress in Photovoltaics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.