Scientists from Qatar's Hamad Bin Khalifa University have designed a novel solar-driven system for brine management and hydrogen production.

Using the engineering equation solver (EES) software, the team simulated the setup and conducted a thermodynamic assessment that included energy, entropy, and exergy balances.

“Brine, if not managed properly, poses severe ecological risks to marine environments. On land, improper brine disposal can cause soil salinization, rendering agricultural lands unproductive and contaminating groundwater supplies,” the researchers said. “This dual challenge of meeting energy demands while mitigating environmental damage highlights the urgent need for integrated solutions that can simultaneously manage brine efficiently and produce clean energy.”

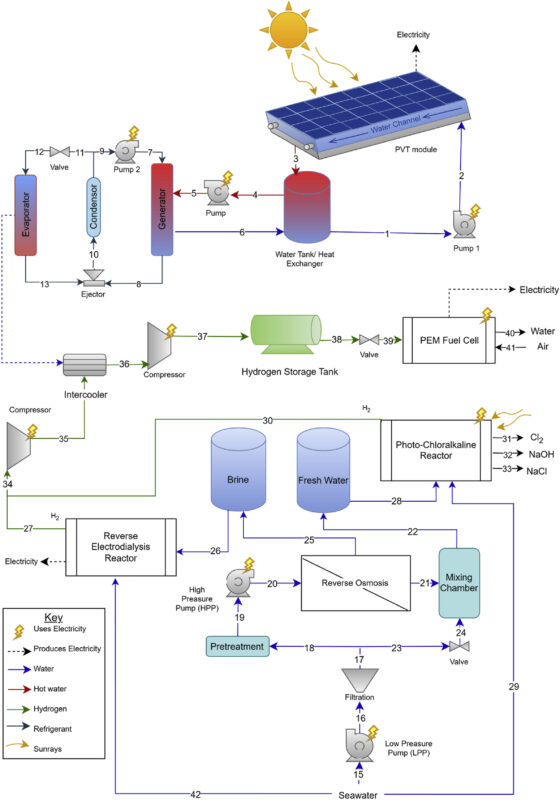

The suggested system is based on a photovoltaic-thermal (PVT) unit that uses the produced energy to power the different system components and the thermal energy to supply its cooling operation. It also includes a reverse osmosis (RO) desalination unit that converts seawater into freshwater and another byproduct. A reverse electrodialysis (RED) then utilizes the salinity from the rejected RO brine, as well as a tank of low-salinity water, to generate electricity and hydrogen.

Further, a photo-chloralkali (PCA) process converts leftover brine into hydrogen, chlorine, and sodium hydroxide, with the help of photo-active material Cu₂O. In addition, the proton exchange membrane (PEM) fuel cell utilizes hydrogen produced in both RED and PCA to generate electricity. An ejector cooling system uses thermal energy from the PV/T unit to provide cooling for different system parts.

Image: Hamad Bin Khalifa University, International Journal of Hydrogen Energy, CC BY 4.0

“The following assumptions are made during the system's analysis: the reference temperature and pressure considered during analysis are 298 K and 101.325 kPa; the sun surface temperature is assumed to be 5700 K; the seawater brine is composed of NaCl. And feed streams to the RED system is the solution of water and NaCl; the isentropic efficiency of the pump and compressor are considered as 85%; the outlet temperature of fluid leaving the PV/T system is 65 C; the system is operating 8 h/day due to solar irradiation limitations,” said the team.

Among different parameters, the academics set an irradiance of 800 W/m2. 610 PV/T panels with a maximum electrical generation of 300 W were placed to power the system, converting up to 20% of the solar energy into electricity, while the rest is used for its thermal product. The RP system had a recovery rate of 0.6, the RED used 100 cell pairs, the PEM used 200 cells, and the PCA unit used 2.5 V.

The system was found to achieve energy and exergy efficiencies of 66.9% and 23.1%, respectively, with the PVT subsystem showing the highest exergy destruction rate. It could produce 18.78 kg/day of hydrogen and 120.6 m³/day of freshwater.

“The RED system generates hydrogen at 0.00041 kg/s, where the production rate increases with rising current density, while the PCA system produces hydrogen at a rate of 0.00024 kg/s,” the academics explained. The PEM fuel cell generates 4.9 kW of electricity, though its efficiency decreases with higher current density.”

They introduced the novel concept in “Thermodynamic analysis of solar-driven integrated system for efficient brine management and hydrogen production,” published in the International Journal of Hydrogen Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.