A research team led by the Indian Institute of Petroleum and Energy (IIPE) has developed a novel solar panel passive evaporative cooling system that utilizes a still seawater layer over a horizontally oriented module.

“Complete or partial submersion of PV modules in water for cooling may cause quality degradation and corrosion of module frames, causing the need for extra protection for the module junction box,” corresponding author H. Sharon told pv magazine. “Hence, we propose a concept where seawater will be allowed to stand still over the module, while the immersion of frames and the junction box is avoided. Moreover, water circulation is also avoided. The concept is safe, economic, and has less environmental impact.”

That cooling technique was experimentally tested against a reference uncooled module, and with varying seawater layer thickness.

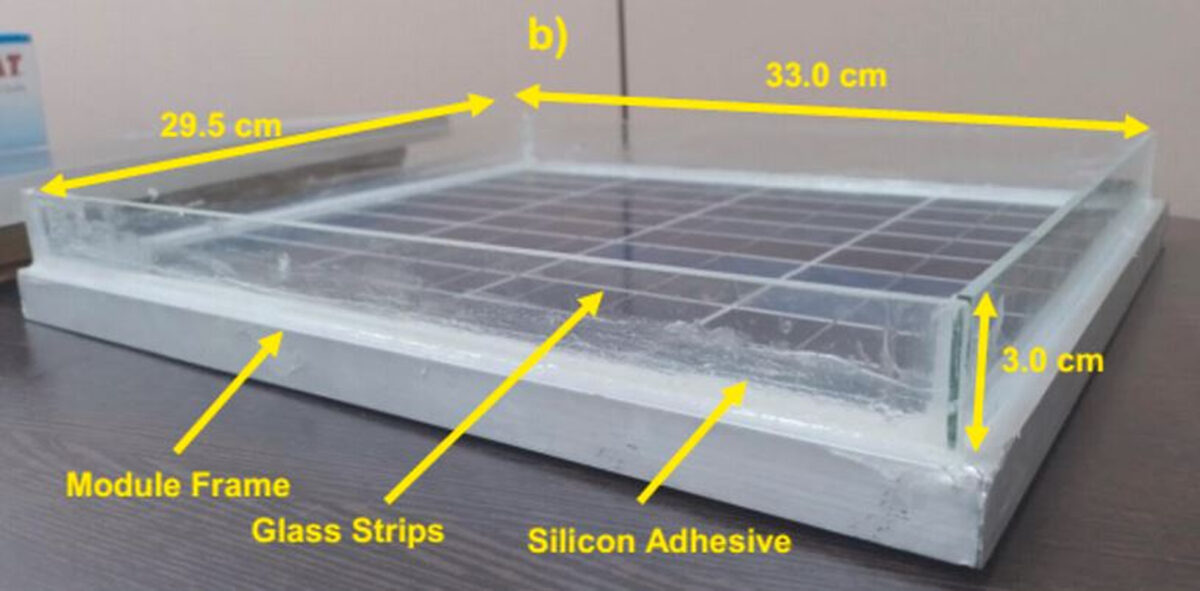

For their study, the group has used a 10 W polycrystalline module, with an area of 0.105 m2. Four clear window glass strips, each 0.003 m-thick and 0.03 m-high, were placed along the module's inner perimeter using silicone adhesive, creating space for seawater. The salinity of the seawater was 30.00 PPT with a pH level of 8.04. The thickness of the seawater layer was either 30 mm, 5 mm, or 4 mm.

“The experiments were conducted on the terrace of the IIPE, Visakhapatnam, India, during four consecutive days in October 2023,” the team said. “In this work, no pumps were utilized, and the seawater was poured manually over the Cool PV module just before the start of each day's experiments. At the end of each day's experiment, the unevaporated water over the module was discarded, and the experiment was resumed the next day with a new batch of seawater. Each experiment lasted from 10:00 to 15:00 h each day, and all the essential readings were manually recorded every 30 min and were used for analysis.”

Image: Indian Institute of Petroleum and Energy (IIPE), Unconventional Resources, CC BY 4.0

On day 1, testing the module with 30 mm of seawater, the average solar radiation intensity was 602.0 W/m2, and the ambient temperature was 30.8 C. On day 2, the layer had a thickness of 4 mm, while the average solar radiation intensity was 555.0 W/m2, and the ambient temperature was 30.5 C. On days 3 and 4, the thickness was 5 mm, the radiation was 781.0 W/m2 and 631.0 W/m2, and the temperatures were 31.8 C and 31.5 C, respectively.

The Cool PV module with an initial 30.0 mm layer of seawater was found to generate 42.2% less daily energy than the reference module because the thick water layer significantly reduced light transmission. In contrast, the module with a 5.0 mm seawater layer produced about 2.57–8.86% more daily energy than the reference module.

Image: Indian Institute of Petroleum and Energy (IIPE), Unconventional Resources, CC BY 4.0

The scientists also found that Cool PV had daily average operating temperatures around 7.6 C, 8.0 C, and 8.0–10.0 C lower than those of the reference module, for thicknesses of 40 mm, 4 mm, and 5 mm, respectively. In addition, salt deposition was observed on the Cool PV module, with a 4.0 mm-thick seawater layer due to dry-out induced by rapid evaporation, aided by relatively low relative humidity and strong wind speed. As a result, its daily energy output dropped by 12.14% compared to the reference module.

“We are planning to do more experimental studies in the near future under different climatic conditions with changing seawater depths and salt concentrations to understand the cool PV module's thermal management ability and year-round performance in a better way,” Sharon concluded.

The passive cooling tech was described in “Photovoltaic module cooling with still seawater layer – Experimental study,” published in Unconventional Resources. Researchers from the Indian Institute of Petroleum and Energy (IIPE), India's Andhra University, and Spain's University of Jaén have participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.