A research group at the University of Exeter investigated a modular, agrivoltaics-powered hydrogen production concept for households. Rooftop agrivoltaics power an electrolyzer that produces hydrogen for hydrogen vehicles and for insulated gasochromic smart windows. The windows are a form of thermally insulating glass that darkens or clears through reversible reactions with hydrogen and oxygen, enabling control of light and heat.

“This research presents a new building-integrated energy concept, linking agrivoltaics, hydrogen, smart façades, and mobility. It offers a fresh perspective on how buildings could become active, multifunctional energy hubs, an idea with growing relevance for future urban energy systems,” researcher Aritra Ghosh told pv magazine. “While the limited roof area naturally restricts total hydrogen output, the value of the concept lies in its system integration and novelty, rather than large-scale production.”

Using multiple software tools, the team simulated a real double-story residential house in Birmingham, England. The building has a total floor area of about 142.7 square meters, a height of 4.8 meters, and 55 square meters of rooftop area available for agrivoltaics. It includes 16 windows across nine thermal zones. Birmingham experiences moderate temperature extremes, with peak summer temperatures of about 21 degrees Celsius and winter lows near 1 degree.

On the flat roof, 12 solar modules were installed in three configurations: vertical, dome-shaped at a 20-degree tilt, or an optimized 30-degree tilt. Each configuration was tested with either 600 W monofacial modules or 605 W bifacial modules. Tomatoes were grown beneath the panels, requiring six to eight hours of direct sunlight per day and nighttime temperatures of about 13 degrees.

A 7 kW electrolyzer with an efficiency of 88% was used to produce hydrogen from the solar output. The hydrogen was modeled for three uses: fueling a 2017 Toyota Mirai, powering the gasochromic windows, or both. The performance of vacuum gasochromic windows was also compared with double-glazing, electrochromic, and standard gasochromic alternatives.

“Using a 55 m2 rooftop area, the system was able to produce enough hydrogen to meet the annual demand of the smart glazing, which was calculated at just 52.56 grams per year,” Ghosh said. “In addition, when the hydrogen output is assessed in terms of mobility, the same rooftop system — using a bifacial PV configuration tilted at 30 degrees – could theoretically support up to 64.23 km of driving per day. This estimate is based on the performance of a 2017 Toyota Mirai, which has a hydrogen tank capacity of 5.6 kg.”

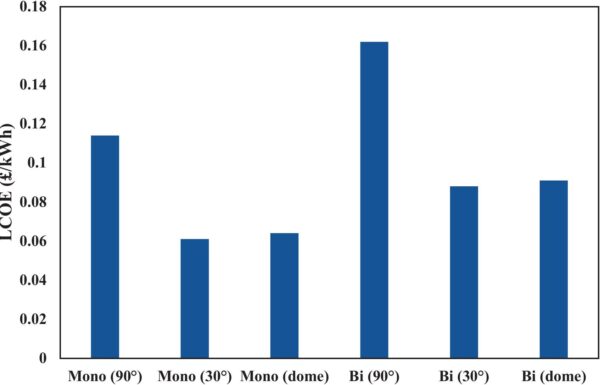

The results showed that the bifacial system at a 30-degree tilt generated the most electricity, at 7,919 kWh annually, while the monofacial 30-degree configuration delivered the lowest levelized cost of electricity at GBP 0.061 ($0.082)/kWh. Tomato yields were consistent across configurations at 0.31 kg per square meter. Among glazing options, vacuum gasochromic windows achieved the best thermal performance, with a U-value of 1.32 W per square meter-kelvin, though at a greater thickness of 24.62 mm.

“While the absolute hydrogen volumes are modest, the results demonstrate how small rooftop areas can support multiple building-scale hydrogen applications, reinforcing the potential of modular, onsite PV–hydrogen systems,” Ghosh said. “The impact of agrivoltaics on home insulation and the optimal use of the produced hydrogen for home heating will be the goal of our further research.

The results were published in Energy and Buildings under the title “Rooftop agrivoltaic powered onsite hydrogen production for insulated gasochromic smart glazing and hydrogen vehicles: A holistic approach to sustainable residential building.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.