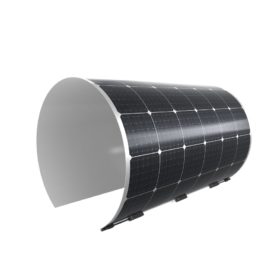

Flexible solar panel for BIPV from Sunport

The module is available in five versions with power output ranging from 310 W to 330 W and efficiencies between 20.22 and 21.53%. The Chinese manufacturer claims the BIPV panel has an oustanding flexibility with minimum curve radius of 25 cm.

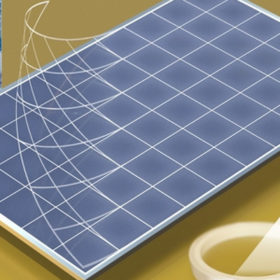

Solar film with integrated optics to increase performance of PV panels

Finnish company ICS has developed a foil which it claims can significantly increase the yield of solar panels, when applied to the edges of a PV module. Germany’s Fraunhofer ISE has confirmed that the increase in performance for conventional solar modules with the solar film is ranging from 5% to 10%.

Trina reveals 600 W module

The Chinese giant has leapt ahead of rivals who recently announced their intent to work towards the next generation of mega panels by pledging to have its 600 W Vertex product on sale by the end of March.

Jinko claims 24.79% efficiency for n-type monocrystalline cell

The Chinese manufacturer has claimed a world record for a large-size, contact-passivated solar cell. The result, certified by Germany’s Institute for Solar Energy Research in Hamelin, betters the company’s previous record by almost 0.6%.

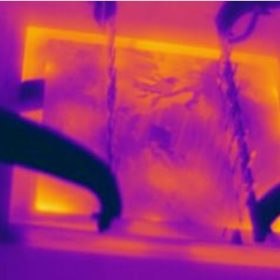

New protocols identify solar cell failures during production

Two new pass/fail protocols are said to be able to separate cells which present high hot-spot possibility, show high current leakage and demonstrate intermediate behavior. The sorting technique relies on a manual solar simulator, an infrared camera and a tool to measure isolation.

The cost of building stronger PV systems

Scientists in the U.S. have estimated the expense of strengthening solar systems. The researchers stressed that the upfront investment needed to take 13 key measures may be outweighed by the benefits.

India’s ReNew Power to build 2 GW factory

The Haryana-based developer will invest up to $266.9 million to set up a new solar cell and module manufacturing facility.

Chinese PV Industry Brief: TCL acquires Zhonghuan, distributed-generation PV soars

TCL, one of China’s biggest electronics manufacturers, has acquired Zhonghuan Semiconductor. The National Energy Administration, meanwhile, reported record growth for the distributed-generation PV segment in June.

URE announces Taiwan factory disposal

The Taiwanese manufacturer said it has sold its Jhunan Kebei plant to a Taiwan-based maker of masks for semiconductor production. However, it will increase capacity at its manufacturing facility in Tainan by up to 200 MW in the third quarter.

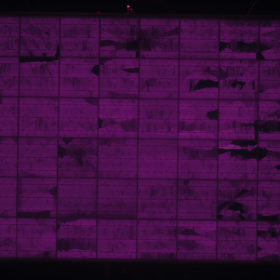

How the cracks are forming

Scientists in the United Kingdom have investigated the formation of cracks in PV cells, confirming that the high temperatures cells are exposed to during soldering for interconnection are a leading cause of cracking. Their findings will aid future research into module reliability and predictions of how cracks are likely to form.